-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

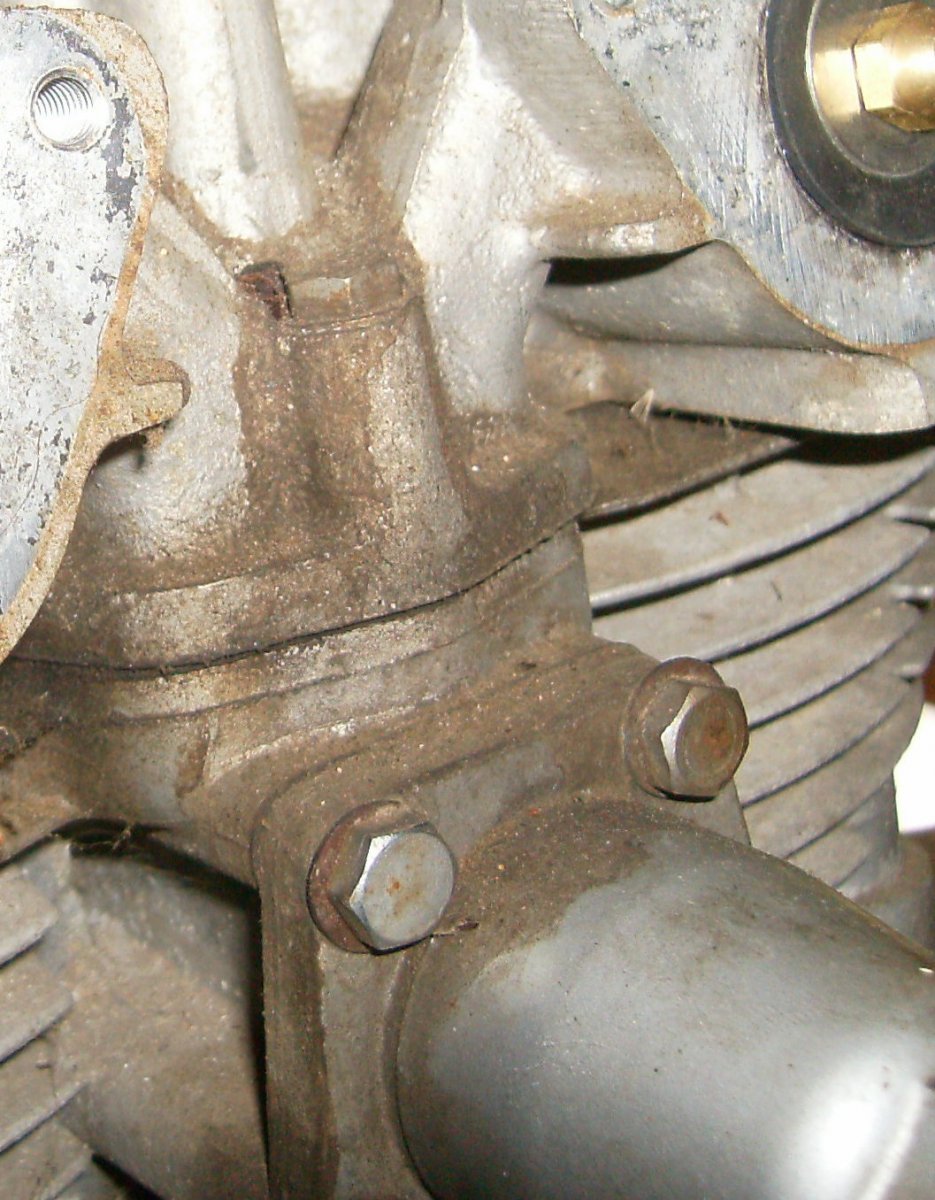

Broken bolt on rebuild asembly

- Thread starter yzwizard

- Start date

Well, I guess it's possible, if you're able to get in there with a drill and then try an EZ-out on it. How much torque were you trying to put on it? Being a small M6 bolt, the spec is only 6 or 7 ft/lbs.

Can you post a pic? Any chance of a Dremel cut off blade could carve out a straight slot to fit a straight blade?

So you’re saying the bolt is bottomed out? If not and just the head broke off flush you may be able to get it out with a little ingenuity. The easy-out is probably the best option but can you post a pic?

DO NOT USE THOSE TAPERED LEFT HAND THREADED "EASY OUTS" !!

Use something like the Ridgid (Ridge Tool Co ?) extractors. They come in a kit with drill guides, drill bits, straight extractors with 6 ribs, and hexagonal "drive nuts"

If you cannot borrow or buy a set, I have had good luck using Torx sockets or bits as extractors. Just select a suitable Torx size, and use a drill bit just large enough to allow you to hammer the Torx bit into the broken stud or bolt.

Use something like the Ridgid (Ridge Tool Co ?) extractors. They come in a kit with drill guides, drill bits, straight extractors with 6 ribs, and hexagonal "drive nuts"

If you cannot borrow or buy a set, I have had good luck using Torx sockets or bits as extractors. Just select a suitable Torx size, and use a drill bit just large enough to allow you to hammer the Torx bit into the broken stud or bolt.

IIRC the hole/threads extend all the way to the cam tensioner passage so it might go "out the bottom".

Last edited:

Your going to struggle with that because of its position.

Here’s on I did but it was easier to access.

I used a torx bit knocked in after drilling into the stud.

Here’s on I did but it was easier to access.

I used a torx bit knocked in after drilling into the stud.

Attachments

It will be well worth the effort to have a sleeve you can drill through so the drill doesn't nick into the threads..

I'm with Arctic on the rigid extractors and the set includes sleeves. They ain't cheap, but often in hindsight......................

I'm with Arctic on the rigid extractors and the set includes sleeves. They ain't cheap, but often in hindsight......................

Is the engine in the frame? Is it working okay the way it is...?

I too don't like easy-outs. If they break off you have a bigger problem. I think of it as do you really think it's not going to break off, if the bolt is so tight it itself broke off?

If the hole does go all the way through, a normal drill bit might eventually catch and turn it on through. If it doesn't go all the way through, it's the kind of thing I would take to a machine shop, personally, and they don't like you if there's a broken easy-out in it.

I too don't like easy-outs. If they break off you have a bigger problem. I think of it as do you really think it's not going to break off, if the bolt is so tight it itself broke off?

If the hole does go all the way through, a normal drill bit might eventually catch and turn it on through. If it doesn't go all the way through, it's the kind of thing I would take to a machine shop, personally, and they don't like you if there's a broken easy-out in it.

I might be tempted to attach a drill bit to a piece of speedometer cable to get access.

It's kind of weird the bolt broke, normally the threads strip out of the cylinder.

It's kind of weird the bolt broke, normally the threads strip out of the cylinder.

The sleeve in the head is as long as the shank on the bolt. The threads are broken off in the cylinder head. So the bolt is broken down in a hole that is an inch deep.

I am taking this out of memory and have not done it myself. saw is somewhere on youtube

If it is broken down in the hole people sometimes take the same size bolt and drill at center hole trough it in a lathe

that hole makes drilling simpler the bolt with the hole made in the lathe is giving guidance for the drill not damaging the thread.

Not sure how drilling is possible at this location if there are room enough for a chuck with angle

There exists also drills with left hand drill bit. It can come loose by that

If not --- the left hand drill bit makes a hole that can be used for extraction

I would put some oil and heat on it first.

Such a difficult location to access with the engine in the frame.

What about just procrastinating on the fix until there is another need to disassemble the engine? Just how important is that bolt to the head anyway? Its hidden, I doubt the head would "warp" if it were left as is while focusing on the rest of the XS's needs this winter..

-R

What about just procrastinating on the fix until there is another need to disassemble the engine? Just how important is that bolt to the head anyway? Its hidden, I doubt the head would "warp" if it were left as is while focusing on the rest of the XS's needs this winter..

-R

For sureI too don't like easy-outs. If they break off you have a bigger problem.

IIRC the hole/threads extend all the way to the cam tensioner passage so it might go "out the bottom".

View attachment 181930

The hole does not pass through , it is 15mm deep from the top of the case.

OK y'all made me think  I had one with stripped threads, drilled it though, tapped it and used a longer bolt.

I had one with stripped threads, drilled it though, tapped it and used a longer bolt.

Back to the OP's prollum.

Back to the OP's prollum.