And to add to that.... the SR guide has the rubber raised in the center. That means the polished rollers of the chain ride on the rubber instead of the links riding in a C channel like the original (and Mikes reproduction). That's gotta be better on the rubber life.Yes, and the whole point of this is so you don't have to buy that questionable MikesXS guide. It's cheaper and may even prove to be a better alternative than an O.E.M. 650 replacement. Like I mentioned in some other threads, I've never heard of an SR guide going bad. The rubber never comes loose and they don't fall apart. I guess bonding rubber to steel works better than trying to bond it to aluminum.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

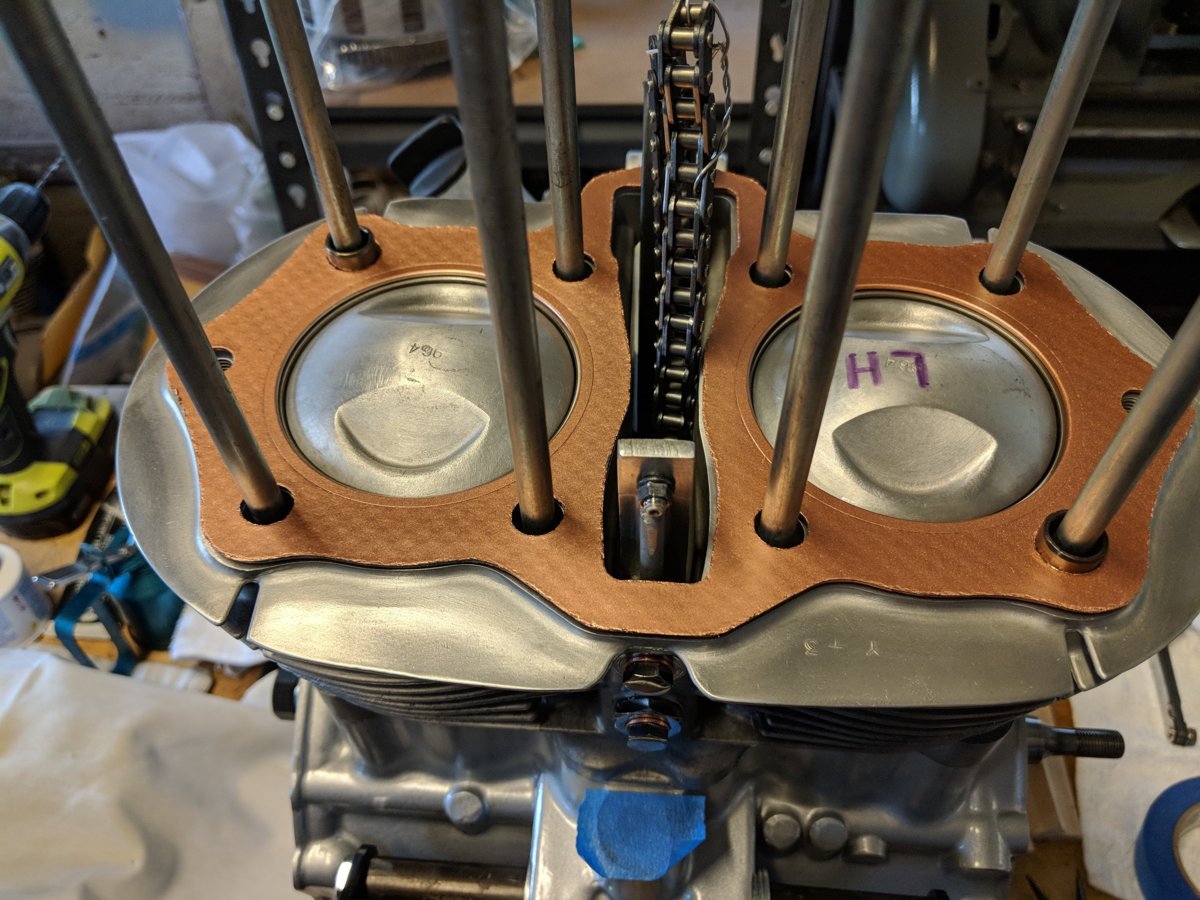

Cam Chain Guide Mod

- Thread starter Jim

- Start date

-

- Tags

- cam cam chain cam chain guide

Gotcha - thanks!

Pete

Pete

Scripto VU

Dukes Speed and Custom

good morning,

the talent on this site never ceases to amaze me. articles like you just posted are what make you as well as many others on this site a 650 a legend a god.

i am still working on my side car frame and my 6 iron. when i get enough courage i will post some pics.

the talent on this site never ceases to amaze me. articles like you just posted are what make you as well as many others on this site a 650 a legend a god.

i am still working on my side car frame and my 6 iron. when i get enough courage i will post some pics.

Hey 5T before you start on this how about making an aluminum block to bolt the SR guide to the 650 cylinder leaving the original guide out of it entirely?

Jim did you consider this? How stiff is that steel on the SR guide? Could it be refolded, bent?

Jim did you consider this? How stiff is that steel on the SR guide? Could it be refolded, bent?

I'm afraid I don't have the fancy tools needed to properly fab up the aluminum block. I don't have a mill, lathe, band saw, or disc sander, and only a very small basic drill press. I think that block is going to take some real machining. It's not just a simple rectangle shape.

C'mon 5T if Allen Millyard can build v12 motors in his back yard... really a drill press should be the only power tool needed.

hmm take one like this SR500 guide.C'mon 5T if Allen Millyard can build v12 motors in his back yard... really a drill press should be the only power tool needed.

make a mount that could be adjusted through one of the existing holes so you could "index" the cam....

And there goes Jims short concise guide thread.

It's just mild steel Gary. It could be re-bent fairly easily. Making a new mounting block is entirely doable. If I had a CNC mill and wanted to do a production run, that would be the way to go. But for a one off like mine.... modding the existing mount is probably your best bet.Hey 5T before you start on this how about making an aluminum block to bolt the SR guide to the 650 cylinder leaving the original guide out of it entirely?

Jim did you consider this? How stiff is that steel on the SR guide? Could it be refolded, bent?

I like that idea.make a mount that could be adjusted through one of the existing holes so you could "index" the cam....

Stuff happens.....And there goes Jims short concise guide thread.

Gary, I don't suppose you have the dimensions on that guide, do you? Looks like it could replace the existing tensioner in the XS and have "raised rubber" guides all around. At $60 from Boats, it's also cheaper than Mikes.

Lovely bit of work.If you want to read the conversation that precipitated this modification,

.

Countersunk HT 4mm or 5mm Allen fastenings are more easily available here, so that's an option. If necessary the head can be ground shallower, depending on hex hole depth.

I'd be inclined to look at also epoxying the new section to the old one, as a belt and braces approach.

Thanks Grimly. I think what I'll do after it's fitted correctly is pull it back apart and bond it with an oil and heat compatible RTV.Lovely bit of work.

Countersunk HT 4mm or 5mm Allen fastenings are more easily available here, so that's an option. If necessary the head can be ground shallower, depending on hex hole depth.

I'd be inclined to look at also epoxying the new section to the old one, as a belt and braces approach.

Something else to try might be an available teflon extrusion or molding riveted to a guide with the face ground flat. It wouldn't have to be anything but a flat slab, I don't think, but it could be milled to ride on the rollers. I appreciate this stuff, especially if the oem guide is not available again. I'm not sure how suspicious we ought to be of mike's guide, I don't know of any specific tales to back it up, all I've read of is successes, but the more sources and alternatives and improvements the better. Complacency isn't what prompts these things.

One thing to remember is if the deflection is not the same the the timing will be off.

One thing to remember is if the deflection is not the same the the timing will be off.

Last edited:

I'm planning a sidecar build in the future. I'd love to see pics of yours!!!i am still working on my side car frame and my 6 iron. when i get enough courage i will post some pics.

nah just grabbed pic off fleabay, it is also off (an older?) sr500Gary, I don't suppose you have the dimensions on that guide, do you? Looks like it could replace the existing tensioner in the XS and have "raised rubber" guides all around. At $60 from Boats, it's also cheaper than Mikes.

Not if it's built anew with one of these in it. Initial setup would be right, and remain right, irrespective of the guide, because this guide is the fixed one. The most it could be would be half a tooth out on initial build and if necessary an adjustable sprocket could be used, if anyone's that fussed about it.One thing to remember is if the deflection is not the same the the timing will be off.

^That's a good point. It's possible only for it to be off by half a tooth worse case  Not sure how significant half a tooth is. Might even help with some old chains... Deflection should still be taken into account for best use of adjuster travel though. And of course keeping stock chain length.

Not sure how significant half a tooth is. Might even help with some old chains... Deflection should still be taken into account for best use of adjuster travel though. And of course keeping stock chain length.

Last edited:

Yes, a little more deflection on the front run would help with an old, worn chain. When the tensioner on the rear chain run pushes the slack out, it rolls the cam back slightly. That retards the timing a little. More and more chain wear/stretch means more and more of a timing change. That's why you eventually run out of timing adjustment on the points plate with a really stretched chain.

But, it would probably be difficult to install a new chain if the front guide stuck in more. A new chain is bow string tight with a stock guide, at least during assembly. I guess they loosen a little rather quickly once you start running the motor. One of the key construction points when making this modded guide is to sand the old guide base down enough so the completed guide doesn't stick in too far. Even if you could get a new chain installed, it might chew into the new guide rather quickly if that guide was pushing in on the chain too much.

But, it would probably be difficult to install a new chain if the front guide stuck in more. A new chain is bow string tight with a stock guide, at least during assembly. I guess they loosen a little rather quickly once you start running the motor. One of the key construction points when making this modded guide is to sand the old guide base down enough so the completed guide doesn't stick in too far. Even if you could get a new chain installed, it might chew into the new guide rather quickly if that guide was pushing in on the chain too much.

Front guide is installed in the motor. The clearance from the top Hi-lok to the head was right at 1/8". I'll put up another comment when I run it.

Similar threads

- Replies

- 39

- Views

- 2K