Thanks, 2M. So it really is the whip as well as the slap - I had been wondering because I've yet to see a drive chain on a bike with a guide on the top run, and the same principle must surely apply. But as you can probably tell, I'm no engineer!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cam Chain Guide Mod

- Thread starter Jim

- Start date

-

- Tags

- cam cam chain cam chain guide

The key difference between a cam timing chain and a final drive chain is that:

- the relationship between the rotational position of the crankshaft and the camshaft in the engine is crucial and if it is not correctly maintained, the engine won’t run properly

- for a final drive chain, the rotational position of the countershaft sprocket and the rear wheel simply doesn’t matter that much. A bit of extra slack in the chain (obviously within reason) won’t hurt anything or affect how the bike operates to any great extent.

Understood, Pete, but what I was thinking about (but didn't mention) was chain life. If controlling sideways whip makes such a difference to wear, then wouldn't that apply to a drive chain too?

Problem with the drive chain of course is that only one sprocket is in a fixed position so maybe that renders any kind of 'whip controller' impractical.

I do like chewing these thoughts over though

Problem with the drive chain of course is that only one sprocket is in a fixed position so maybe that renders any kind of 'whip controller' impractical.

I do like chewing these thoughts over though

Indeed - and yes, a fully guided and lubed chain in an enclosure is best - that’s just not practical for a drive chain.

I mentioned in another thread that I had made up a little holding tool for the old guides to help hold them and keep them square to the table while sanding them down. Jim asked if I'd post a couple pics. The "tool" is nothing more than a short length of angle iron with 2 holes drilled in it. The holes needed to be quite low to get the guide to sit square to the table. It required a bit of grinding to provide bolt head clearance. This was accomplished with a cut-off wheel in a Dremel .....

A simple effective solution. That's the best kind. I like it. Thanks for sharing.

Not to 'muddy the waters', Jim, but during the disassembly of "The Basketcase" (I was saving this for "Episode II - The Phantom Motor"), which, in its defense, has only 9,333 miles, the cam chain guide looked virtually pristine! Completely intact, no missing chunks, no delamination, nothing! I was going to put it back in when the motor goes back together... I will replace it, eventually, I'm sure. And when I do, your SR500 mod will certainly be considered. Great write up!

Hokey dokey sportsfans:

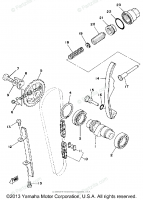

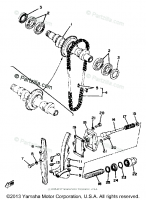

I have finally cleared away some of the nonesense that I laughingly call “my life” and have taken a few photos of the “JimD Frankenguide” alongside a standard OEM XS650 timing chain guide. The photo below shows a perspective and an end-on view of the SR500 Frankenguide (right) and a slightly used OEM guide on the left. Note that the OEM guide has a channel running down its length while Jim’s SR500 adaptation has a raised centre “rail” instead.

Totally aside from the differences in the wear strip material (discussed below) - I feel (and I think that Jim may agree) that the central rail SR500 design is superior to the older XS650 “channel” geometry because the rail contacts only the nice smooth surfaces of the chain rollers rather than the potentially sharp edges of the chain links themselves. That is important because the typical failure mode on the XS650 guide is that those thin raised edges of the channel wear and eventually fall off and then the entire plastic slipper surface eventually fails and drops off the metal guide shoe. That is what happened with Lucille’s guide during the middle of the summer.

Jim’s design addresses both failure modes by using the new SR500 slipper surface with its raised rail design and by incorporating mechanical fasteners on the assembly to keep things together. See below: the upper photo is the XS650 and the lower one is Jim’s Frankenguide.

On the matter of the slipper surface materials:

My conclusion is that the old hard shiny stuff has been superseded in recent times by the softer dull-toned material - on just about all timing chain guides and that makes it OK in my book. In addition, I would bet that if the XS650 had stayed in production much longer, Yamaha would have moved to the raised rail timing chain guide geometry as they did on the more recently designed SR500 engine.

CONCLUSION

So, I continue my reign as The King of Timing Chain Guides as I now have two MikesXS guides (un-used), a used 1975 guide which looks quite OK to me and Jim’s SR500/XS650 Frankenguide. I will likely freshen up the top end of my ‘81 Special cafe bike at some point in the next year or so and I will use Jim’s guide in that bike.

In the meantime, we can look forward to Jim’s testing of his guide in his shiny snazzy Special and that will help to confirm that the Frankenguide is a viable alternative to the MikesXS guide - which definitely has some manufacturing issues.

I think that we all owe Jim a huge vote of thanks for his innovation on this. He has addressed a key durability issue on the XS650 with the incorporation of the new OEM Yamaha SR500 timing chain guide - and that is important as the supply of NOS Yamaha XS650 timing chain guide parts seems to have totally dried up in the last few months.

Cheers,

Pete

I have finally cleared away some of the nonesense that I laughingly call “my life” and have taken a few photos of the “JimD Frankenguide” alongside a standard OEM XS650 timing chain guide. The photo below shows a perspective and an end-on view of the SR500 Frankenguide (right) and a slightly used OEM guide on the left. Note that the OEM guide has a channel running down its length while Jim’s SR500 adaptation has a raised centre “rail” instead.

Totally aside from the differences in the wear strip material (discussed below) - I feel (and I think that Jim may agree) that the central rail SR500 design is superior to the older XS650 “channel” geometry because the rail contacts only the nice smooth surfaces of the chain rollers rather than the potentially sharp edges of the chain links themselves. That is important because the typical failure mode on the XS650 guide is that those thin raised edges of the channel wear and eventually fall off and then the entire plastic slipper surface eventually fails and drops off the metal guide shoe. That is what happened with Lucille’s guide during the middle of the summer.

Jim’s design addresses both failure modes by using the new SR500 slipper surface with its raised rail design and by incorporating mechanical fasteners on the assembly to keep things together. See below: the upper photo is the XS650 and the lower one is Jim’s Frankenguide.

On the matter of the slipper surface materials:

- the OEM XS650 guide (reportedly removed from a 1975 bike) is made of a very hard and shiny material;

- the slipper surface on the SR500 guide is a softer dull-toned material - just about identical to the stuff used in the new generation MikesXS guides

My conclusion is that the old hard shiny stuff has been superseded in recent times by the softer dull-toned material - on just about all timing chain guides and that makes it OK in my book. In addition, I would bet that if the XS650 had stayed in production much longer, Yamaha would have moved to the raised rail timing chain guide geometry as they did on the more recently designed SR500 engine.

CONCLUSION

So, I continue my reign as The King of Timing Chain Guides as I now have two MikesXS guides (un-used), a used 1975 guide which looks quite OK to me and Jim’s SR500/XS650 Frankenguide. I will likely freshen up the top end of my ‘81 Special cafe bike at some point in the next year or so and I will use Jim’s guide in that bike.

In the meantime, we can look forward to Jim’s testing of his guide in his shiny snazzy Special and that will help to confirm that the Frankenguide is a viable alternative to the MikesXS guide - which definitely has some manufacturing issues.

I think that we all owe Jim a huge vote of thanks for his innovation on this. He has addressed a key durability issue on the XS650 with the incorporation of the new OEM Yamaha SR500 timing chain guide - and that is important as the supply of NOS Yamaha XS650 timing chain guide parts seems to have totally dried up in the last few months.

Cheers,

Pete

Last edited:

I absolutely agree Pete.... and thanks for the comment. As 5twins has previously stated, he's never seen the rubber come off the SR500 guide. And the Hiloks give us about a thousand lbs. of sheer force... yeah, way overkill there. Those facts and the ones you stated should make for a guide that will last practically forever.I feel (and I think that Jim may agree) that the central rail SR500 design is superior to the older XS650 “channel” geometry because the rail contacts only the nice smooth surfaces of the chain rollers rather than the potentially sharp edges of the chain links themselves.

When I put my SG engine together I had the choice of a NOS guide, a Mikes guide or the frankenguide. I chose the frankenguide 'cause I think it's the better, longer lasting one.

The raised center is good, but I think there are benefits to having the sides forming a channel like in the original. Because -- if the chain is way loose or the guide crooked, or etc., the chain my simply slip off the guide = nightmare. Maybe combine the two ideas. I'm not following this thread at all but someday will probably benefit from y'all's work here.... I feel (and I think that Jim may agree) that the central rail SR500 design is superior to the older XS650 “channel” geometry because the rail contacts only the nice smooth surfaces of the chain rollers rather than the potentially sharp edges of the chain links themselves. ...

Pete

I could probably make the argument that if one lets the chain get that loose, this hobby's really not for you....The raised center is good, but I think there are benefits to having the sides forming a channel like in the original. Because -- if the chain is way loose or the guide crooked, or etc., the chain my simply slip off the guide = nightmare. Maybe combine the two ideas. I'm not following this thread at all but someday will probably benefit from y'all's work here.

Truth is there isn't room for it to slip off.

I don't think the front run of the chain gets very loose. The crank is pulling down on it, pulling it taught. The slack or slop ends up in the rear run of the chain where Yamaha put the spring-loaded (and adjustable) tensioner. That's probably why they put it there.

If there isn't room for it to come off that's good then.I could probably make the argument that if one lets the chain get that loose, this hobby's really not for you....

Truth is there isn't room for it to slip off.

But the thought that if you let it get that loose you shouldn't have it is wrong -- when you design something you must absolutely make it idiot proof. In business it keeps the phone from ringing, and it's just good conscientious engineering practice. Blaming the customer for something you could have prevented doesn't work. I've seen it many times and it was always the worst solution to the problem

The fact that there ain't room for it to fall off kinda makes it idiot proof.... no?when you design something you must absolutely make it idiot proof.

I ain't in business... problem solved.In business it keeps the phone from ringing

I ain't an engineer....and it's just good conscientious engineering practice.

We'll leave aside for a second that I don't have customers to blame.... There was nothing there for me to prevent. Again, there ain't room for the chain to fall off.Blaming the customer for something you could have prevented doesn't work.

Looks to me like your saying I should have engineered a fix to a problem that don't exist to satisfy some customers I don't have. Or have I completely misunderstood?

It does. That's what I meant by "that's good". No problem. But if it could come off, if the user was being an idiot, and it comes off, everyone will rightly say why did he make it so it could come off... If a plane control cable comes loose if the pilot is being an idiot, what you must do is make it so it won't come loose even if he is being an idiot. Not harping, just being theoreticalThe fact that there ain't room for it to fall off kinda makes it idiot proof.... no?

OK. 'theoretically speaking'....

The chain needs to be tightened periodically. Either you do it yourself, or you pay someone to do it. But if the manual says it needs to be tightened periodically (it does)... and the owner blows that off to the point it causes damage... then I'm sorry, but it's the owner that's the idiot, not the engineer who plainly stated "hey this chain wears. Tighten it up at X interval."

Even aircraft control cables aren't "absolutely idiot proof." They're cables... they stretch. On any aircraft I've ever worked on, they're checked and adjusted every 100 hrs. A pilot is the final authority to determine an aircraft is safe for flight. If he flies an airplane that's gone... say 500-1000hrs. without the cables being inspected and adjusted... then yeah... he's an idiot. Stuff wears. Chains and cables stretch. Engineers tell us that because you can't "idiot proof" normal wear, here's a periodic maintenance schedule to account for that. If you don't follow it, you're an idiot.

Someone once said that you can't make something idiot proof.... 'cause idiots are so smart. There's a grain of truth there.But the thought that if you let it get that loose you shouldn't have it is wrong -- when you design something you must absolutely make it idiot proof.

The chain needs to be tightened periodically. Either you do it yourself, or you pay someone to do it. But if the manual says it needs to be tightened periodically (it does)... and the owner blows that off to the point it causes damage... then I'm sorry, but it's the owner that's the idiot, not the engineer who plainly stated "hey this chain wears. Tighten it up at X interval."

Even aircraft control cables aren't "absolutely idiot proof." They're cables... they stretch. On any aircraft I've ever worked on, they're checked and adjusted every 100 hrs. A pilot is the final authority to determine an aircraft is safe for flight. If he flies an airplane that's gone... say 500-1000hrs. without the cables being inspected and adjusted... then yeah... he's an idiot. Stuff wears. Chains and cables stretch. Engineers tell us that because you can't "idiot proof" normal wear, here's a periodic maintenance schedule to account for that. If you don't follow it, you're an idiot.

Last edited:

Guys, please! We're dabbling in the rarified air of experimental R & D here. Postulating on the theoretical...  JimD has been spending a lot of time and effort on one of the Xs's greatest weaknesses. And this motorcycle doesn't have many. But if it was a perfect machine (ya know, like the '98 Mauser, the DC-3... okay, I'm out of examples

JimD has been spending a lot of time and effort on one of the Xs's greatest weaknesses. And this motorcycle doesn't have many. But if it was a perfect machine (ya know, like the '98 Mauser, the DC-3... okay, I'm out of examples  ), would we be doing all this wonderfully inspirational tinkering?

), would we be doing all this wonderfully inspirational tinkering?

JimD has been spending a lot of time and effort on one of the Xs's greatest weaknesses. And this motorcycle doesn't have many. But if it was a perfect machine (ya know, like the '98 Mauser, the DC-3... okay, I'm out of examples

JimD has been spending a lot of time and effort on one of the Xs's greatest weaknesses. And this motorcycle doesn't have many. But if it was a perfect machine (ya know, like the '98 Mauser, the DC-3... okay, I'm out of examples  ), would we be doing all this wonderfully inspirational tinkering?

), would we be doing all this wonderfully inspirational tinkering?

FB71

Expert Turd Polisher

^^^ A-10 Thunderbolt II

Similar threads

- Replies

- 39

- Views

- 2K