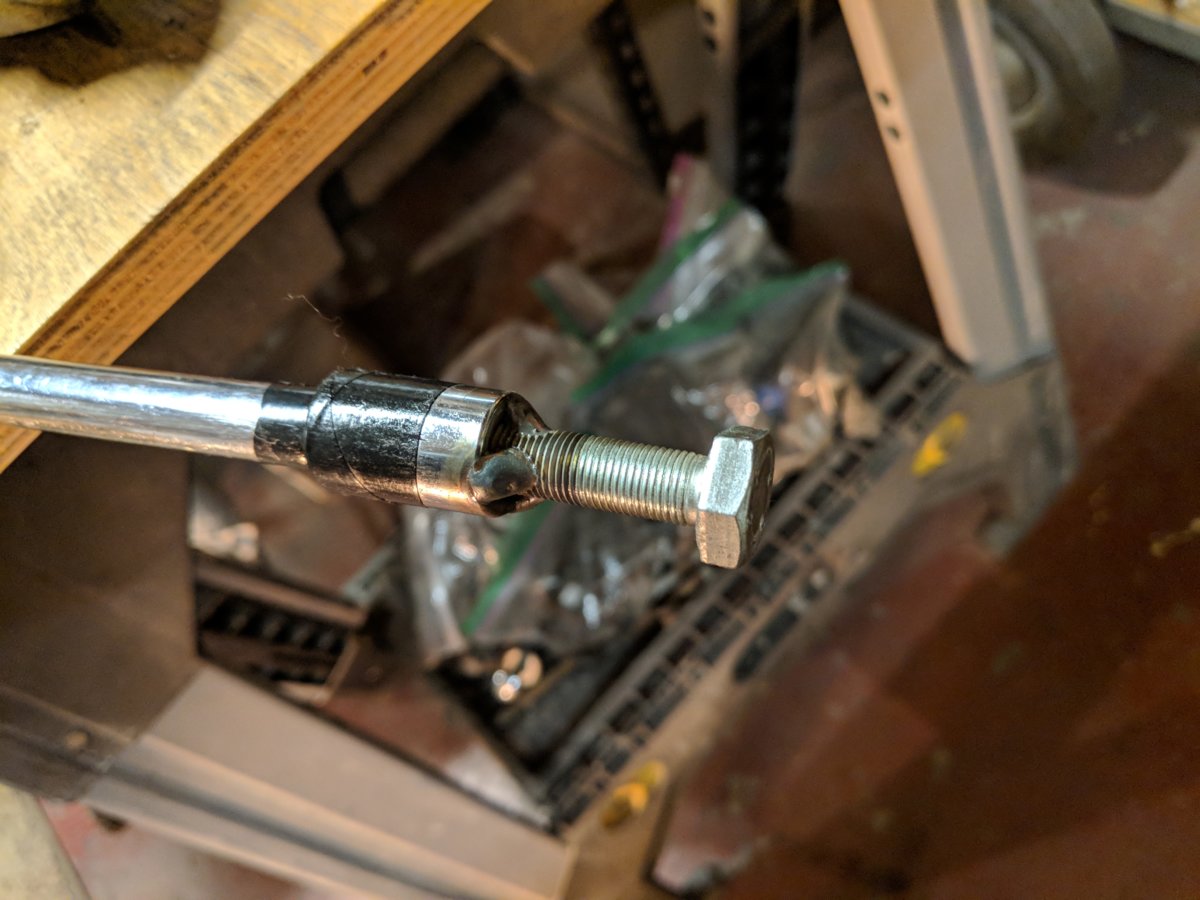

I read lots of stuff on this site about ways to make a simple tool for holding the damper rod on late 35mm forks, but if you don't have welding kit to hand then spending a while with a file (no bench grinder or lathe available) and a wheel spindle key is time well spent. Well, it worked for me today! My one has a 3/8 drive and a 3/8 to 1/2 adapter:

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cheap fork rebuild tool

- Thread starter nighthog

- Start date

That’s an excellent adaptation nighthog!

Note: the 34mm forks on ‘76 and earlier XS650s use a totally different fork rod fitting from that depicted above.

Note: the 34mm forks on ‘76 and earlier XS650s use a totally different fork rod fitting from that depicted above.

Yup. But hopefully this may help someone with the late ones like I have. If you zoom in on the pic you'll see where the filing was done, enough to allow it to pass down inside the stanchion. Crude but effective

My next problem is removing the seals. The damned things feel like they're welded in - shifting them without damaging the sliders looks tricky. The usual approach of jamming a big flat blade screwdriver tip under and twisting (not levering) got me nowhere. They're presently soaking in WD40 and it'll be a couple of weeks until I can attack them again, but all suggestions/advice gratefully received.

My next problem is removing the seals. The damned things feel like they're welded in - shifting them without damaging the sliders looks tricky. The usual approach of jamming a big flat blade screwdriver tip under and twisting (not levering) got me nowhere. They're presently soaking in WD40 and it'll be a couple of weeks until I can attack them again, but all suggestions/advice gratefully received.

Yup - when I did mine (‘76 - so the slightly smaller 34mm dia. units) they were stuck and I found that a previous owner HAD gouged the inside of the LH slider. I dressed it with a dremel wheel and a bit of emery cloth and it seems ok.

If you search for “Forking around with Lucille” - you can see nice photos of the damage.

I eventually used one of those nasty seal puller hooks - but as you say....BE CAREFUL.

Pete

If you search for “Forking around with Lucille” - you can see nice photos of the damage.

I eventually used one of those nasty seal puller hooks - but as you say....BE CAREFUL.

Pete

Last edited:

Yes, these seals can be pretty stuck in there, lol. It's best you make up some sort of protection for the top of the fork lower so you don't damage it by prying. A simple little protection "tool" can be make up from a piece of scrap aluminum angle with a couple slits cut in one side and a "finger" tab bent down. It will sit in and on top of the lower all by itself and protect it while you pry .....

For removal, I "sacrificed" a big old square shank screwdriver I had laying around by filing the tip round. The square shank keeps it from rolling while in use. This, combined with the protection angle, makes up my special little fork seal removal "tool kit" .....

I work my way around the seal, prying a little bit in multiple spots, until it breaks free. I've encountered some tough ones but haven't met one yet that has defeated my special little "kit".

For removal, I "sacrificed" a big old square shank screwdriver I had laying around by filing the tip round. The square shank keeps it from rolling while in use. This, combined with the protection angle, makes up my special little fork seal removal "tool kit" .....

I work my way around the seal, prying a little bit in multiple spots, until it breaks free. I've encountered some tough ones but haven't met one yet that has defeated my special little "kit".

5Twins - brilliant!!

You Sir - ARE the Man.

I’m savin’ that one!!!

Pete

You Sir - ARE the Man.

I’m savin’ that one!!!

Pete

Agreed! Love that idea and I have an old tax disc holder I can cut and bend ...

Thanks

Thanks

I took these pics to illustrate the use of the "special tools". The wire retaining ring and metal washer are still in place on top of the seal. Obviously, you have to remove those first before trying to get the seal out. Thought I better mention that, lol.

You took the forks off your bike just to reply to this thread? Now I'm REALLY impressed

Last edited:

Sorry, kinda figured those pics weren't taken in the last few hours but it was too good a leg pulling opportunity to miss!

I soak a rag in hot water and wrap that around the slider where the seal sits for 2-3 min. and then use a flat tire iron with a protecter on top of the slider acouple bumps and they pop out. The hot water expands the aluminum to help let go of the seal.

Nighthog - FYI, 5Twins has the most incredible library of well composed photos of darned near everything in, on or related to XS650s.

As I said, he IS the Man.

As I said, he IS the Man.

I used one of these star socket thingeys.... can't remember what they're called. Size E-14

And then pounded a bolt with a 17mm head into it. I went ahead and welded it.... just because I can, but as hard as it was pounding it in, I'd bet it would stay without welding.

And then pounded a bolt with a 17mm head into it. I went ahead and welded it.... just because I can, but as hard as it was pounding it in, I'd bet it would stay without welding.

Pete, I wouldn't disagree for a moment. I sincerely hope I didn't offend.

For the fork seals I make these....

First thing you do is cut as much of the seal rubber out as you can. Only takes a sec.

Install the angles and bolt together....

Take a steel rod and insert in the other end 'till it slips into the nut....

Set the lower in a soft jaw vise....

Give 'er a sharp smack or two on the rod, and out pops the seal on the other end. Easy peazy....

No worries about damaging the lower this way...

First thing you do is cut as much of the seal rubber out as you can. Only takes a sec.

Install the angles and bolt together....

Take a steel rod and insert in the other end 'till it slips into the nut....

Set the lower in a soft jaw vise....

Give 'er a sharp smack or two on the rod, and out pops the seal on the other end. Easy peazy....

No worries about damaging the lower this way...

Last edited:

I like these fork seal removal ideas.

I have found that a Harbor Freight tire tool works great. I love 5 twins aluminum protector and going to make one at work. In the past I just used whatever I had lying around.

I have found that a Harbor Freight tire tool works great. I love 5 twins aluminum protector and going to make one at work. In the past I just used whatever I had lying around.

Pete, I wouldn't disagree for a moment. I sincerely hope I didn't offend.

Oh heck no nighthog. That was just information and to encourage you to ask questions. We’re all pretty hard to offend here!

JIM - I really like that little gizmo you made. Very clever!

I installed the new seals in Lucille with a threaded rod rig - the thought of using a hammer near a hard to replace chunk of aluminium does not appeal to me.

Jim, that's excellent, I really like the thinking behind it. Nice one.

Similar threads

- Replies

- 20

- Views

- 4K