YL82

Perpetual Restorationist

I've got (work) access to some high-grade granite Starrett Surface Plates to check my cylinder head for any warpage or un-flatness

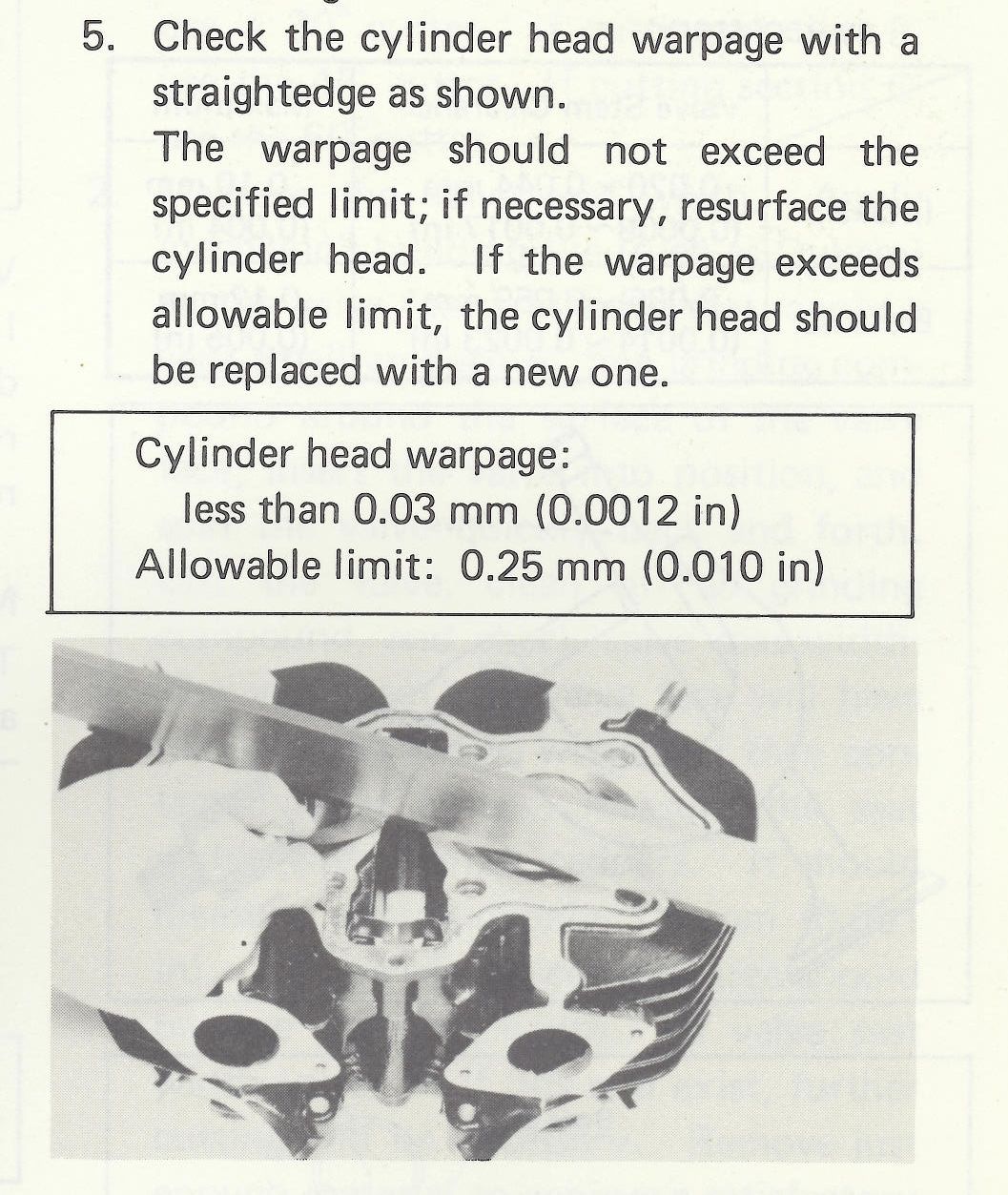

Do I need to use something so accurate or is using a precision straightedge and feeler gauges at several locations generally adequate?

Or even using plate glass to check for any rocking?

Perhaps a silly question, but does the top of the cylinder block also need to be checked as well or just the cylinder head?

Thanks.

Do I need to use something so accurate or is using a precision straightedge and feeler gauges at several locations generally adequate?

Or even using plate glass to check for any rocking?

Perhaps a silly question, but does the top of the cylinder block also need to be checked as well or just the cylinder head?

Thanks.