I'm going to build one as an "adapter" that will allow me to mount it on my full-size engine stand. When I get it done, I'll take photos and measurements and post them here.

I did one when I was futzing with a 750 Triple a few years back, and it's WELL worth the time to fab one up so you don't have to screw around trying to balance the motor on a bench while torquing something.

BTW, I still have the one for the 750 if anyone wants it. I won't be needing it again.

I did one when I was futzing with a 750 Triple a few years back, and it's WELL worth the time to fab one up so you don't have to screw around trying to balance the motor on a bench while torquing something.

BTW, I still have the one for the 750 if anyone wants it. I won't be needing it again.

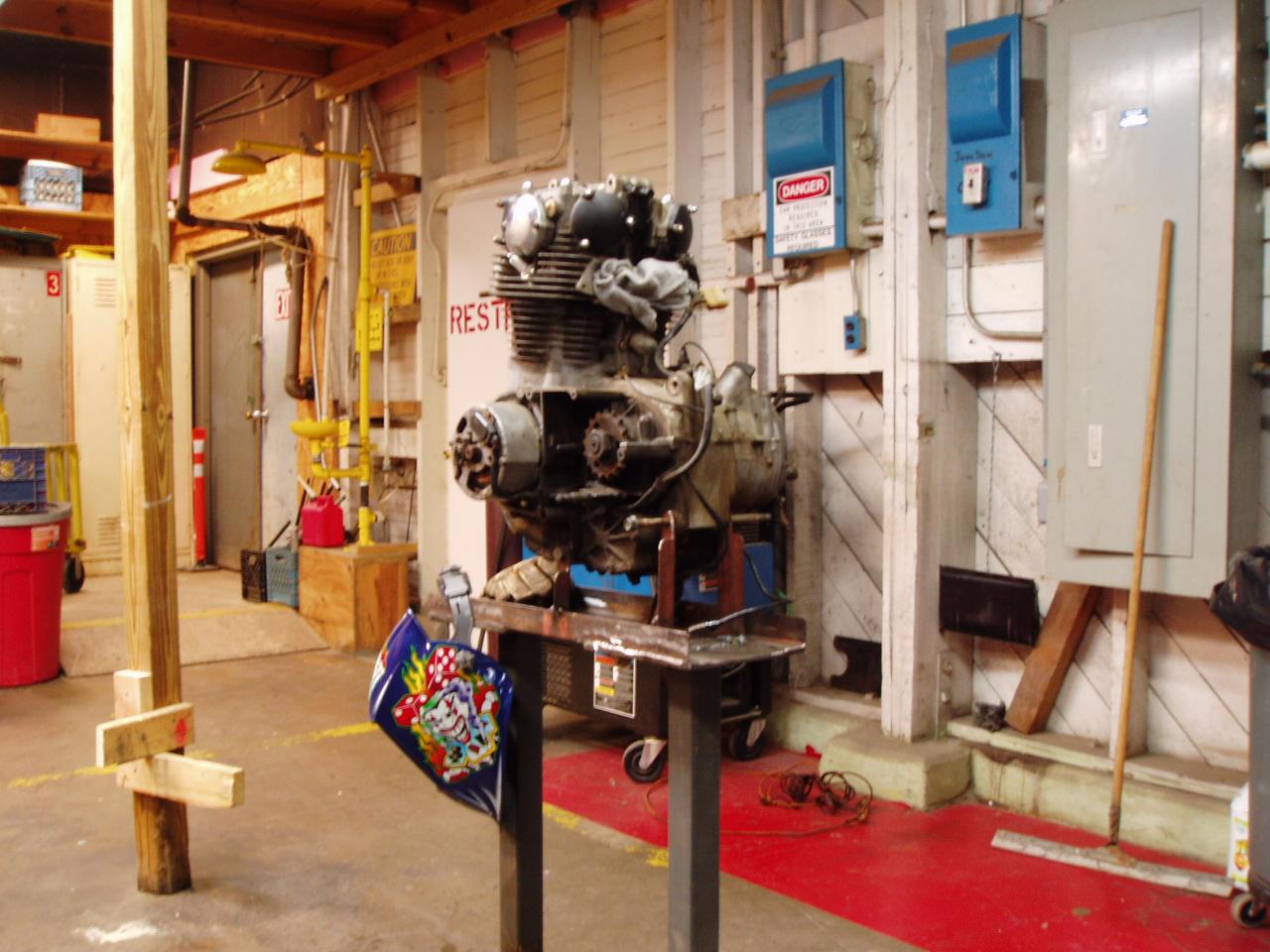

Ill take a pic and put it here I think the engine mounting post are backwards they should be swiched

Ill take a pic and put it here I think the engine mounting post are backwards they should be swiched