I made myself a short list of checks before closing the crankcases which was very helpful to me as this is the first XS650 engine I have worked on. I didn't even have the advantage of stripping the engine myself as I bought it already stripped in a box of bits. I thought perhaps this might be useful to anyone else rebuilding their engine for the first time.

PARTS REQUIRED

Clutch pushrod oil seal 8x25x6mm, Crankshaft oil seal 26x40x9m, Output shaft oil seal 40x62x9mm

The following M8 fixings 2x 75mm bolts, 1x 90mm bolt and 1x 55mm bolt, 12x plain washers, 6x copper washers, 6x Acorn nuts and 12x plain nuts (all M8 )

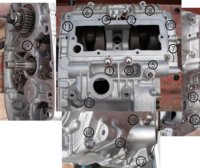

LAST CHECKS BEFORE CLOSING THE CRANKCASE

1. Check that the crankshaft bearings are seated correctly by trying to spin the bearing cases

2.Check imput and crankshaft half moon retaining rings are fitted and the 2x case locating dowels.

3. Check cam chain seated on crankshaft sprocket and tails hanging equal length when crank is at TDC

4. Check primary and output shafts seated correctly and turning

5. Check correct gear change operation through all the gears

6. Check cross over shaft and pinions fitted to lower case. (easier when cases are open)

7. Check that the rubber or aluminium bung is fitted to end of gear drum selector shaft

8. Check clutch pushrod bush for play (renew if required)

9. Apply Yambond or similar to the 3x oil seal housings in the upper case half and fit the 3x oil seals

10. Liberally lubricate the cross over shaft ,pinions , bearings, gear clusters, gear selector drum etc , carefully avoiding any mating surfaces of the crankcases

11. Apply liquid gasket to the mating face of the lower crankcase and the 3x oil seal housings .Small makeup brush is ideal !

12. Lower the lower crankcase onto upper crankcase and persuade to close with rubber hammer.

If the cases do not close to within 2-4mm before tightening then something is not right and you may need to lift the lower case off again and recheck that everything is seated properly, particularly the 4x crankshaft bearings and each of the 3x oil seals .

It then just remains to tighten all the 18 No nuts and bolts to 14 ft-lbs in sequence. Minimum of 4 tightening stages are recommended ( note that 4x of the bolts are underneath on the jug side of the case and 3x of the nuts are to the sides of the case)

PARTS REQUIRED

Clutch pushrod oil seal 8x25x6mm, Crankshaft oil seal 26x40x9m, Output shaft oil seal 40x62x9mm

The following M8 fixings 2x 75mm bolts, 1x 90mm bolt and 1x 55mm bolt, 12x plain washers, 6x copper washers, 6x Acorn nuts and 12x plain nuts (all M8 )

LAST CHECKS BEFORE CLOSING THE CRANKCASE

1. Check that the crankshaft bearings are seated correctly by trying to spin the bearing cases

2.Check imput and crankshaft half moon retaining rings are fitted and the 2x case locating dowels.

3. Check cam chain seated on crankshaft sprocket and tails hanging equal length when crank is at TDC

4. Check primary and output shafts seated correctly and turning

5. Check correct gear change operation through all the gears

6. Check cross over shaft and pinions fitted to lower case. (easier when cases are open)

7. Check that the rubber or aluminium bung is fitted to end of gear drum selector shaft

8. Check clutch pushrod bush for play (renew if required)

9. Apply Yambond or similar to the 3x oil seal housings in the upper case half and fit the 3x oil seals

10. Liberally lubricate the cross over shaft ,pinions , bearings, gear clusters, gear selector drum etc , carefully avoiding any mating surfaces of the crankcases

11. Apply liquid gasket to the mating face of the lower crankcase and the 3x oil seal housings .Small makeup brush is ideal !

12. Lower the lower crankcase onto upper crankcase and persuade to close with rubber hammer.

If the cases do not close to within 2-4mm before tightening then something is not right and you may need to lift the lower case off again and recheck that everything is seated properly, particularly the 4x crankshaft bearings and each of the 3x oil seals .

It then just remains to tighten all the 18 No nuts and bolts to 14 ft-lbs in sequence. Minimum of 4 tightening stages are recommended ( note that 4x of the bolts are underneath on the jug side of the case and 3x of the nuts are to the sides of the case)

Its good to know that it was useful to somebody .

Its good to know that it was useful to somebody .