ANLAF

XS650 Guru

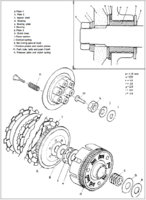

I am about to re-assemble my clutch on my 1979 XS-SF. TwoMany has warned me to be careful of the washer/bearing/spacer stacking sequence so I been reading through some threads and there are a great number of posts about the clutch warning of inaccurate schematics and manuals (not showing parts that should be there). I wonder if anyone can point me to the CORRECT SCHEMATIC DIAGRAM.

I have been trying to trace the cause of the inability to select neutral. All the clutch mechanisms (worm gear, push rods, clutch cable) have now been cleaned, lubricated and adjusted - perhaps my clutch plates I've just taken out had something to do with it (they measured just 2mm).

ANLAF

I have been trying to trace the cause of the inability to select neutral. All the clutch mechanisms (worm gear, push rods, clutch cable) have now been cleaned, lubricated and adjusted - perhaps my clutch plates I've just taken out had something to do with it (they measured just 2mm).

ANLAF