Hey everyone, hope you had a good weekend. I'd be grateful for you opinions on whether or not this hub needs machining on a lathe or just a good passover with sandpaper o glass beading?

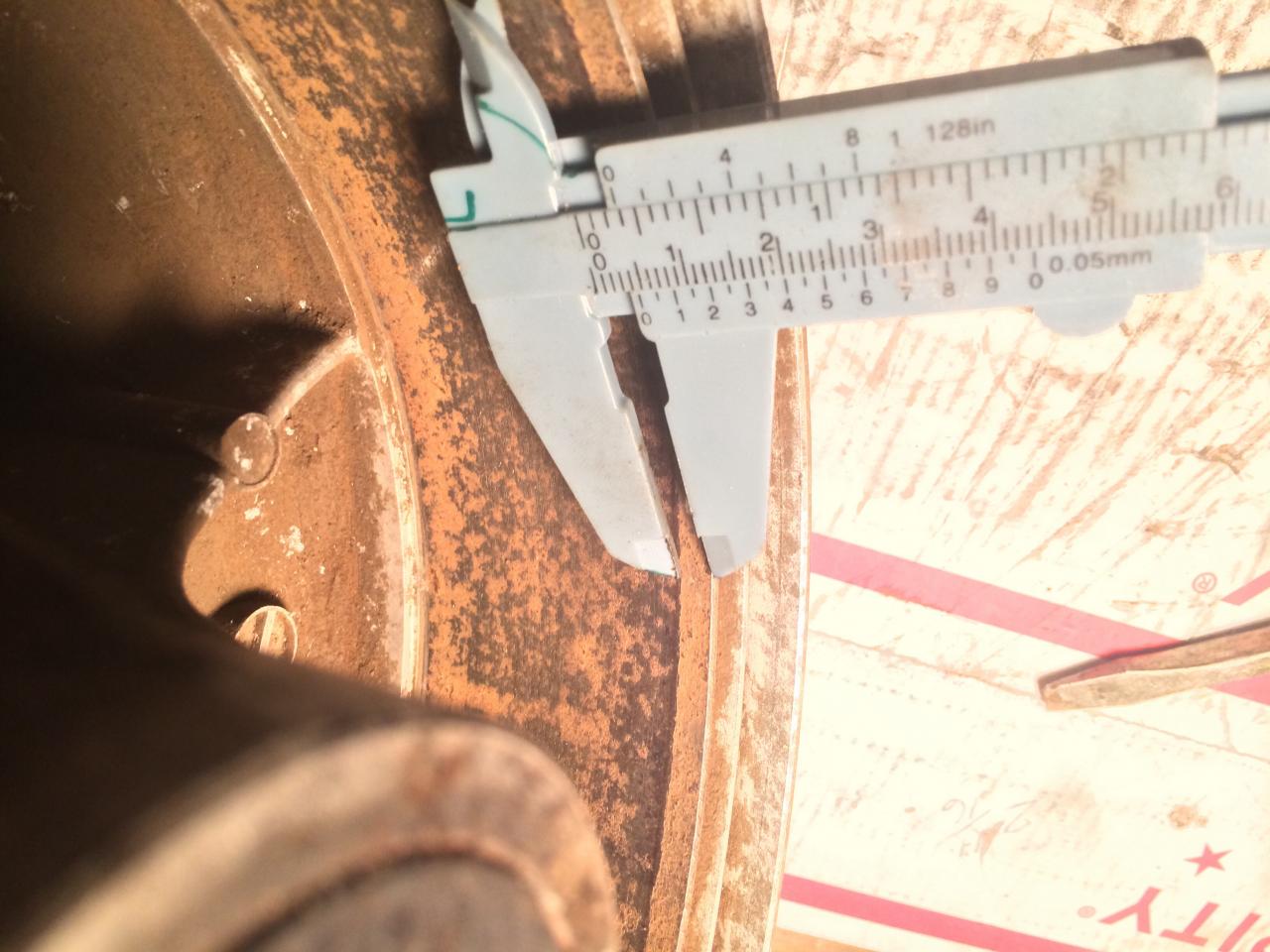

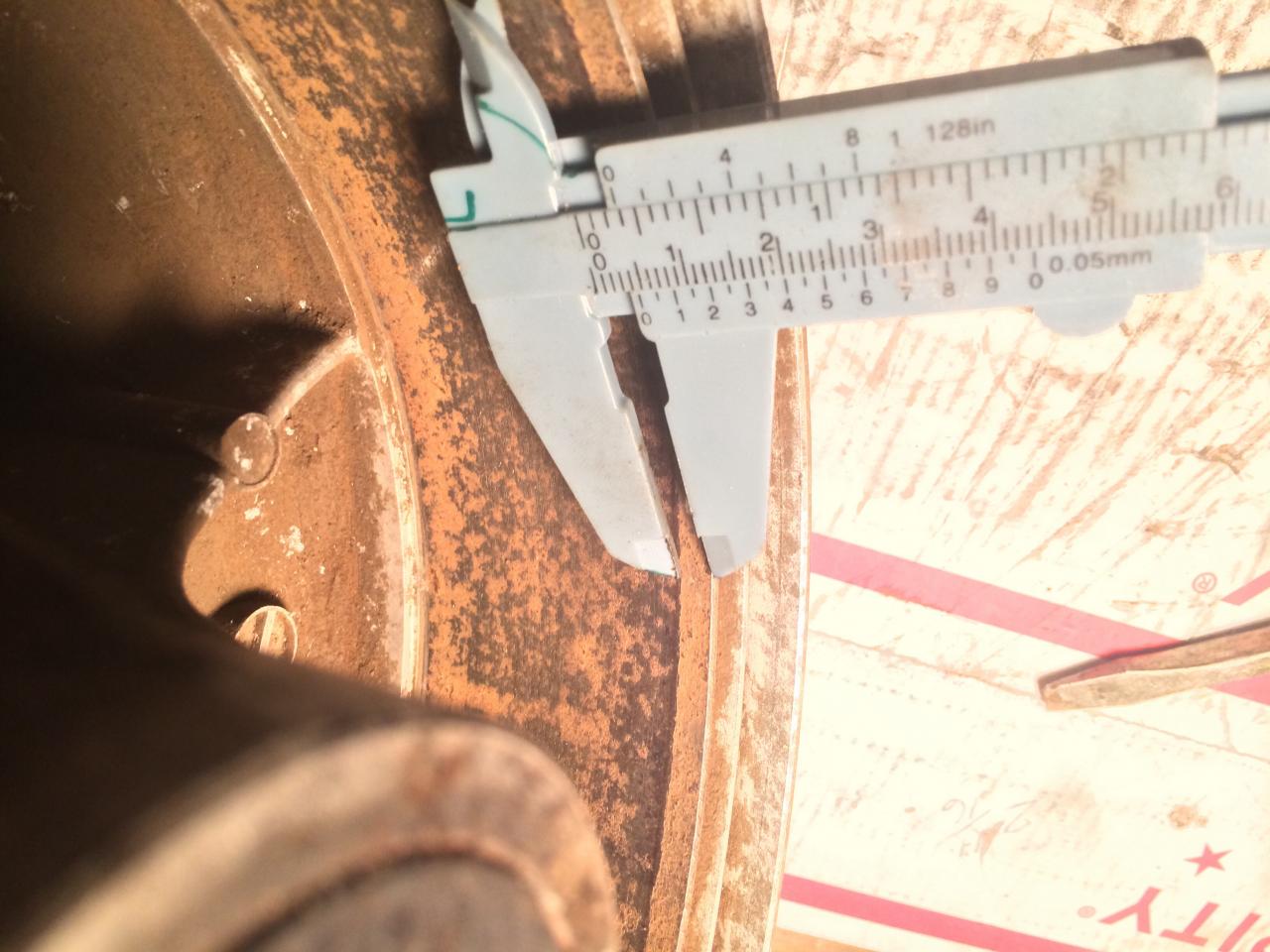

As background, there was a pronounced 3-4mm wide lip that was about 1mm high at the edge of the hub. The "lip" is in the pics with my high quality calipers and the small screwdriver pointing to "lip" area.

I originally thought this lip was due to worn brake pads grinding down the iron of the inner hub, leaving the 3-4mm of metal on the edge.

But I scrubbed the insides down with steel wool a little and the lip scrubbed off, so cool. I think it was just 40 years of brake dust build up.

I don't have any experience with brake rotors, but I DID read 5Twins excellent posting on refurbishing rear hubs, and I will do this.

But I didn't find a lot on when you should machine a hub.

The brake shoes are shot, and I'll be getting new ones. What would you do with this hub? Do brake shops machine motorcycle hubs? I'll call around but wanted to float it by you all first. I believe that if I machine it on a latheI should wait until after the hub is laced up with the rim.

As background, there was a pronounced 3-4mm wide lip that was about 1mm high at the edge of the hub. The "lip" is in the pics with my high quality calipers and the small screwdriver pointing to "lip" area.

I originally thought this lip was due to worn brake pads grinding down the iron of the inner hub, leaving the 3-4mm of metal on the edge.

But I scrubbed the insides down with steel wool a little and the lip scrubbed off, so cool. I think it was just 40 years of brake dust build up.

I don't have any experience with brake rotors, but I DID read 5Twins excellent posting on refurbishing rear hubs, and I will do this.

But I didn't find a lot on when you should machine a hub.

The brake shoes are shot, and I'll be getting new ones. What would you do with this hub? Do brake shops machine motorcycle hubs? I'll call around but wanted to float it by you all first. I believe that if I machine it on a latheI should wait until after the hub is laced up with the rim.

Flapper sounds good, better than milling jk

Flapper sounds good, better than milling jk

50 HP won't do Mach1? I'll be hard pressed to do 80mph.

50 HP won't do Mach1? I'll be hard pressed to do 80mph.