Highside

Lord of the Flies

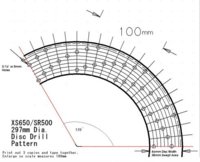

Is there a quick and easy pattern for drilling holes in a stock front rotor? or do I just have to sit and try to figure out a hole pattern myself??

I could do this on mastercam, but I'm having a lazy moment.

I could do this on mastercam, but I'm having a lazy moment.

check out the Vault in 650 rider

check out the Vault in 650 rider