Lets face it... we ain't gettin no younger. I don't know about you guys, but 15-20 minutes of stop and go traffic (which is common here in KC) and my forearms feel like I spent and hour in the gym.

So, here's an idea I been thinkin about for years but never pulled the trigger on: An electric clutch assist using a 12V pull solenoid like this...

This particular one has an inch and a half throw with 4lbs. of force. Only uses 10 Watts of power and costs about 25 bucks. It would take some measuring and a little trial and error to pin down exact figures but lets roll with this one for now...

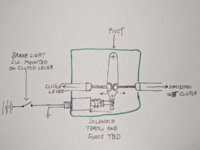

My idea is to mount this solenoid in an "intermediate box" that could be hidden under the tank. The clutch cable would go from the lever to the box and another cable would go from the box to the engine (clutch). A brake light switch mounted to the clutch lever would energize the solenoid, helping pull the clutch cable through a lever, giving a slight mechanical advantage. When the clutch lever is released, spring pressure would (already does) unload the throw out bearing. Here's a quick drawing...

Lets say for shits and grins that it takes 10lbs. pull on the lever to disengage the clutch. As soon as you pull the lever, the solenoid energizes and it would be instantly reduced to 5lbs. Could even use a stronger solenoid for even more reduction. When you release the lever, solenoid would release and the full 10lbs would engage the clutch just as it does now.

The cool part is that this is scalable to any bike and could probably be made for under a hundred bucks.

I smell patent materiel here Like any good science project though, first ya gotta try and poke holes in it. So poke away guys! Lets talk this out and see if it will actually work.

Like any good science project though, first ya gotta try and poke holes in it. So poke away guys! Lets talk this out and see if it will actually work.

I guess the first question is... has this been done before? Am I pissin in the wind re-inventing the wheel?

So, here's an idea I been thinkin about for years but never pulled the trigger on: An electric clutch assist using a 12V pull solenoid like this...

This particular one has an inch and a half throw with 4lbs. of force. Only uses 10 Watts of power and costs about 25 bucks. It would take some measuring and a little trial and error to pin down exact figures but lets roll with this one for now...

My idea is to mount this solenoid in an "intermediate box" that could be hidden under the tank. The clutch cable would go from the lever to the box and another cable would go from the box to the engine (clutch). A brake light switch mounted to the clutch lever would energize the solenoid, helping pull the clutch cable through a lever, giving a slight mechanical advantage. When the clutch lever is released, spring pressure would (already does) unload the throw out bearing. Here's a quick drawing...

Lets say for shits and grins that it takes 10lbs. pull on the lever to disengage the clutch. As soon as you pull the lever, the solenoid energizes and it would be instantly reduced to 5lbs. Could even use a stronger solenoid for even more reduction. When you release the lever, solenoid would release and the full 10lbs would engage the clutch just as it does now.

The cool part is that this is scalable to any bike and could probably be made for under a hundred bucks.

I smell patent materiel here

I guess the first question is... has this been done before? Am I pissin in the wind re-inventing the wheel?