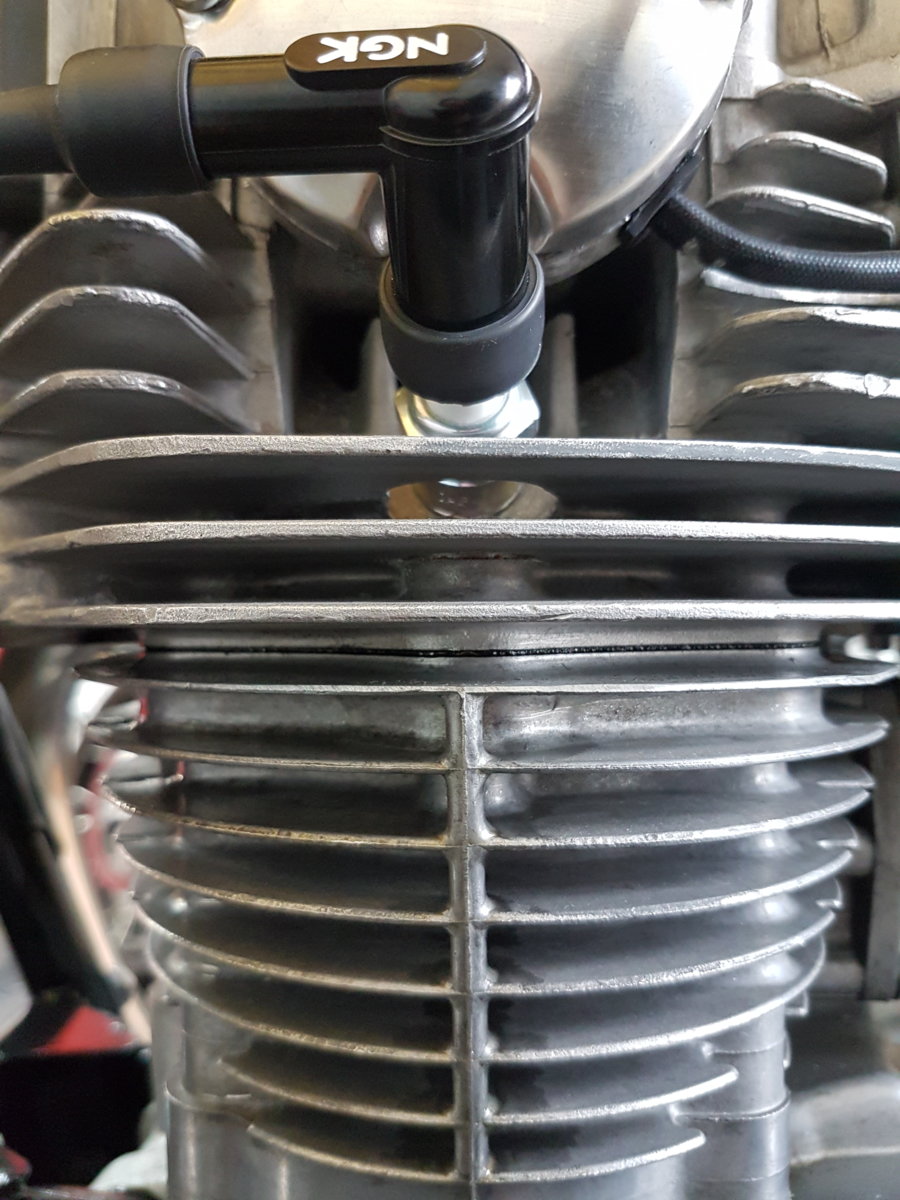

Ok, the points housing is 100% clean of oil. Oil was definitely coming from that gasket. I have been busy searching the site for info, I found this written by yourself:

"I pull the 8 large acorns, one at a time, clean if need be, anti-seize, then torque up to 25. When all 8 have had that done, I go back around and bring them up to 30. Then I pull the ones under the plugs, one at a time and follow the same routine - clean and anti-seize. These get torqued to a lower value though because they're smaller, 16 I think. Those are the only bolts and nuts that effect the head and base gasket. The other small ones on top of the head just hold the top cover on. There is that little M6 bolt back down between the carbs that is part of the head gasket pattern but it doesn't do a whole lot and you probably can't get at it anyway. Most head gasket leaks don't occur in the back by that little bolt anyway. They usually occur across the front and along the sides"

I'm going to follow this, is this still the method you use? I read it's also good practice to replace the 4 x outer rubber coated acorn washers with bronze or brass (thick) ones, I will need to find these before I start.

One last thing, your torque ratings are in ft/lb - I have converted these to NM for Metric reference:

25 ft/lb = 34 Nm

30 ft/lb = 41 Nm

16f ft/lb = 22 Nm

If anyone has the size of the cylinder head nut washer I would be grateful - imperial fine/I can convert - Yambits in the UK only stock the original rubber coated type which I do not want!