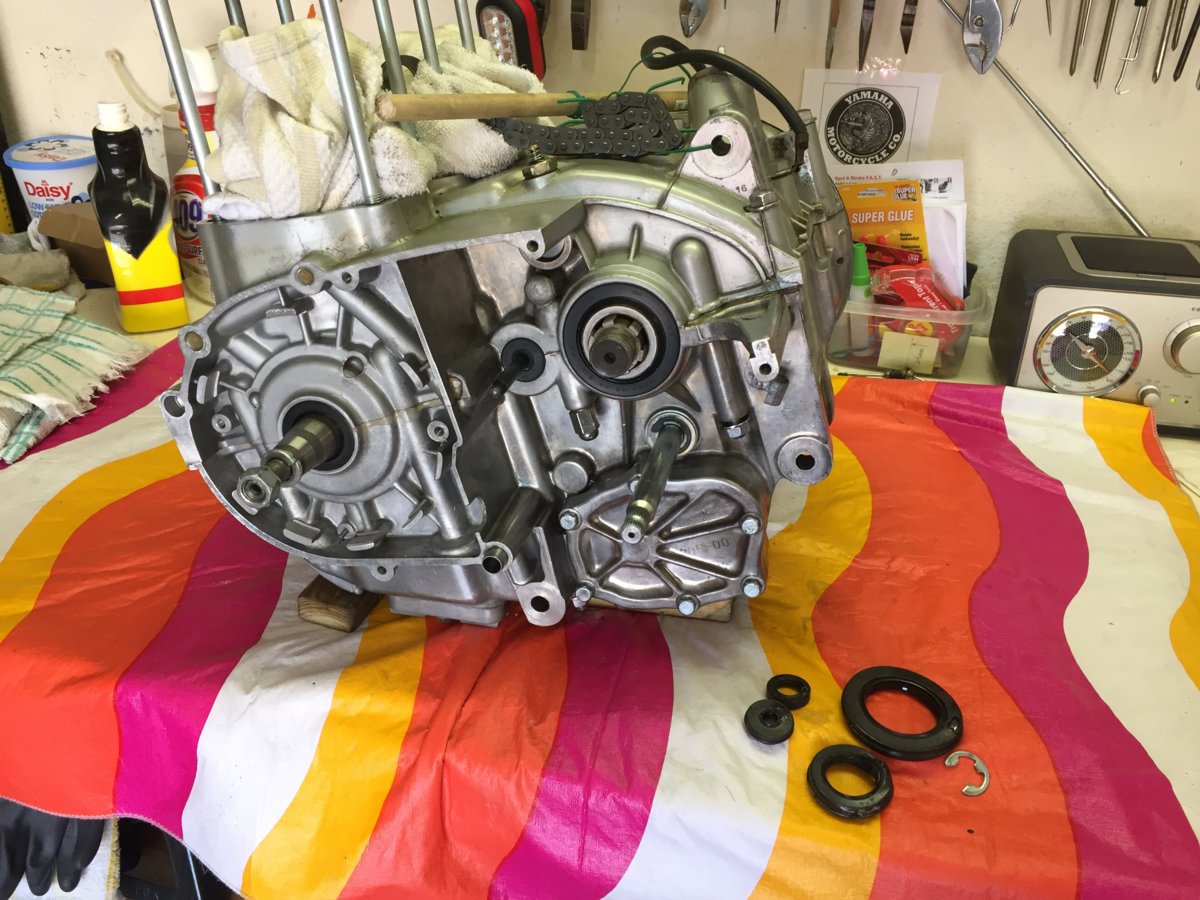

In this installment of engine seal replacements I shall be tackling the big dogs under the left side case, the crankshaft seal and the driveshaft seal. For both of these seals I’ll be relying on using my seal puller. Available online or through Harbor Freight, and probably auto part stores.

In the past I have just placed the tip against a seal and drove it into the seal with a hammer, but I thought I would try to be a little more precise by drilling an entry point into the seal exactly where I want it.

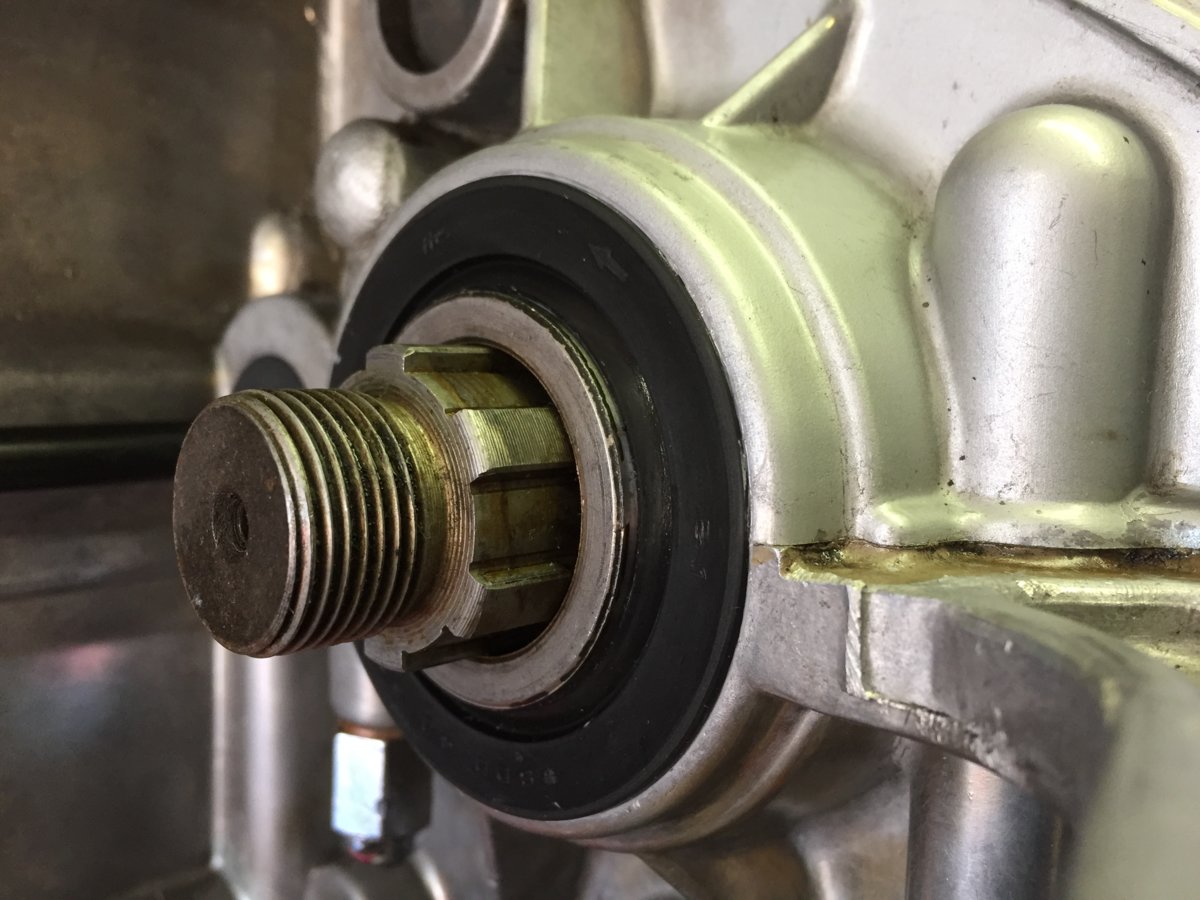

So I started with the drive shaft seal. I drilled a small hole right in the lettering on the outside of the seal. I’ve discovered that if you go right into the lettering it puts you in just the right place on the seal, you’ll see in a moment. It turned out I needed a slightly larger hole due to the awkward angle I had to enter from. So I opened it up a little and then drive my puller into the hole with a small hammer, and pried against a block of wood so I didn’t mar the case.

Same position viewed from below.

Here you can see how it entered the seal from the front ( I cut the rubber away to view ) and then an inside view to show you how the puller hooks into the inside of the seal. There is a steel band that is penetrated.

The case opening for the driveshaft is a machined edge and is sharp. It will need to be beveled with a deburring tool prior to installing the seal. This tool is available on eBay or at your local hardware store.

Be sure to clean up the case opening thoroughly. I vacuum out the opening just to be sure there is no debri.

Wipe everything down so you have a clean surface , and if needed , I used an Xacto knife to carefully scrape old sealant off of the case opening. This seal and the crankshaft seal will get a thin smear of Yamabond around the outside edge, before installing.

Once again I am forgoing any sort of driver in favor of a small 1 X 2 block of wood to slowly , lightly tap the seal into place. I find the block of wood gives me a great feel and view of what’s going on.

The seal is now in, just wipe it clean and I’m done.

There really is no point in doing a separate write up for the crankshaft seal , since it is another large seal that goes in the same way. The only thing I would add is that since the crank seal will be sliding over the crankshaft, I wiped the shaft and the inner seal with silicone to get a smooth installation and avoid damaging the seal. Also the crankshaft seal opening in the case has a relieved edge and does not need to be deburred.

So, all my seals on the left side have now been replaced. It’s really not hard and you don’t have to have a lot of fancy tools. The only ones I bought specifically for replacing seals was the puller and the deburring tool.

I hope someone, someday finds this helpful.

-Bob

In the past I have just placed the tip against a seal and drove it into the seal with a hammer, but I thought I would try to be a little more precise by drilling an entry point into the seal exactly where I want it.

So I started with the drive shaft seal. I drilled a small hole right in the lettering on the outside of the seal. I’ve discovered that if you go right into the lettering it puts you in just the right place on the seal, you’ll see in a moment. It turned out I needed a slightly larger hole due to the awkward angle I had to enter from. So I opened it up a little and then drive my puller into the hole with a small hammer, and pried against a block of wood so I didn’t mar the case.

Same position viewed from below.

Here you can see how it entered the seal from the front ( I cut the rubber away to view ) and then an inside view to show you how the puller hooks into the inside of the seal. There is a steel band that is penetrated.

The case opening for the driveshaft is a machined edge and is sharp. It will need to be beveled with a deburring tool prior to installing the seal. This tool is available on eBay or at your local hardware store.

Be sure to clean up the case opening thoroughly. I vacuum out the opening just to be sure there is no debri.

Wipe everything down so you have a clean surface , and if needed , I used an Xacto knife to carefully scrape old sealant off of the case opening. This seal and the crankshaft seal will get a thin smear of Yamabond around the outside edge, before installing.

Once again I am forgoing any sort of driver in favor of a small 1 X 2 block of wood to slowly , lightly tap the seal into place. I find the block of wood gives me a great feel and view of what’s going on.

The seal is now in, just wipe it clean and I’m done.

There really is no point in doing a separate write up for the crankshaft seal , since it is another large seal that goes in the same way. The only thing I would add is that since the crank seal will be sliding over the crankshaft, I wiped the shaft and the inner seal with silicone to get a smooth installation and avoid damaging the seal. Also the crankshaft seal opening in the case has a relieved edge and does not need to be deburred.

So, all my seals on the left side have now been replaced. It’s really not hard and you don’t have to have a lot of fancy tools. The only ones I bought specifically for replacing seals was the puller and the deburring tool.

I hope someone, someday finds this helpful.

-Bob