This is a continuation of the Experimental Clutch thread:

http://www.xs650.com/threads/yamaha-xs650-experimental-clutch.47498/

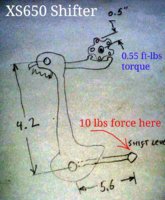

In that thread, I've determined that the clutch isn't the primary cause of difficulty in trying to find Neutral while stopped and the transmission is in 1st or 2nd gear. In this this thread, I'll be experimenting with the shifting components, starting with the more easily accessed starwheel parts.

This video shows typical XS650 shifter actuation:

http://www.xs650.com/threads/yamaha-xs650-experimental-clutch.47498/

In that thread, I've determined that the clutch isn't the primary cause of difficulty in trying to find Neutral while stopped and the transmission is in 1st or 2nd gear. In this this thread, I'll be experimenting with the shifting components, starting with the more easily accessed starwheel parts.

This video shows typical XS650 shifter actuation: