Yeah.... does sound low. Depends on the gearing. Can you give me a tooth count on your sprockets? Fwiw.... if that tach is bad, I'll give you another one.When I was going around 65 on the highway in 4th the tach read around 3.5-4. That seems too low?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First highway run; engine bogs at 60

- Thread starter tzimmerm

- Start date

With stock gearing, sprockets, and wheels, in 5th gear, you can guesstimate rpms from speed as 15mph per 1,000 rpms.

1,000 rpms = 15mph

2,000 rpms = 30 mph

3,000 rpms = 45 mph

4,000 rpms = 60 mph

5,000 rpms = 75 mph

6,000 rpms = speeding ticket

4,000 - 4,500 rpms are in a zone that's sensitive to exhaust reversion, especially if running open pipes.

Describe your exhaust....

1,000 rpms = 15mph

2,000 rpms = 30 mph

3,000 rpms = 45 mph

4,000 rpms = 60 mph

5,000 rpms = 75 mph

6,000 rpms = speeding ticket

4,000 - 4,500 rpms are in a zone that's sensitive to exhaust reversion, especially if running open pipes.

Describe your exhaust....

there has to be something seriously wrong with your engine if you can only manage 65-70mph .!

My bike will get to 70mph in third gear in a matter of seconds up a steep hill ! It will rev comfortably to 6000rpm, probably more but its unnecessary to do so ...better to change up around 5500rpm I find with no loss of performance

I am not sure what benefit there is diagnostically to red line the engine ?

I would start with the basics and try and find out what the engine is doing.

Don't remove your carbs yet ...better to do some diagnostics to establish what is wrong first.

1. Post a picture of your spark plugs but keep them identified with the cylinder they came out of.

2. carry out a compression test of both cylinders .

3. tell us what happens when you open the throttle to increase speed does the engine cough and splutter? or does it bog down like its fuel starved ?

Does the engine backfire at all ? or just seem sluggish to increase speed .

My bike will get to 70mph in third gear in a matter of seconds up a steep hill ! It will rev comfortably to 6000rpm, probably more but its unnecessary to do so ...better to change up around 5500rpm I find with no loss of performance

I am not sure what benefit there is diagnostically to red line the engine ?

I would start with the basics and try and find out what the engine is doing.

Don't remove your carbs yet ...better to do some diagnostics to establish what is wrong first.

1. Post a picture of your spark plugs but keep them identified with the cylinder they came out of.

2. carry out a compression test of both cylinders .

3. tell us what happens when you open the throttle to increase speed does the engine cough and splutter? or does it bog down like its fuel starved ?

Does the engine backfire at all ? or just seem sluggish to increase speed .

Diversion: I saw a note back in the thread about fuel lines. For the last year I have been using Tygon F-4040-A fuel line. This is transparent and colored yellow to clearly identify it as fuel line. It remains flexible and shows only the slightest swelling with UK petrol. I use the 6.4mm ID tube. Currently selling at £10 for a 1 meter length which is enough to refit my 81' 3 times. It is widely used on all those model planes with their special nitro-fuels and small petrol machines like hedge trimmers and chainsaws. Expensive compared to most tubing, but does the job very well!

Why is your idle so.???......... High Have you set the idle with the idle stop screw to 1500 yourself???.............1100-1200 is where it should be.

Everything on the bike is stock, sprockets, exhaust; wheels. The exhaust is rusted out toward the back of the pipes and you can hear it when you’re riding. I set the idle with the adjustment screw. Much lower and it will die. The bike does backfire occasionally. I’ll try to get pics of everything. God this is already becoming a huge expensive project that I can’t afford. I’m already way over budget and I’m spending more on tools. It’s very discouraging.

I just went through this entire thread.

Yellow, oily stuff on or near the carbs is evaporated gas residue.

Do the slide drop test.

Replace the carb boots and gasket OR at the least throw some non hardening "form a gasket" seal on the intake gasket.

Count the teeth on those gears, front and rear.

Bench synch the carbs.

Yellow, oily stuff on or near the carbs is evaporated gas residue.

Do the slide drop test.

Replace the carb boots and gasket OR at the least throw some non hardening "form a gasket" seal on the intake gasket.

Count the teeth on those gears, front and rear.

Bench synch the carbs.

I’m trying to upload a video of me coldstarting the bike this morning. It’s taking it a while. It’s probably too big. I do have to make a correction to my previous statement about idle-I have the idle set at just over 1000 rpm’s. You can see it in the video.

Wrap those gaps in duct tape and see how it runs, I don't think you'll see much of a difference.

I saw your avatar, thought you were working on the open-pipe chopper. Now understand it's sold, and you're working on a stocker. Forget the exhaust query.

Try this:

At 25mph, in 3rd gear, fully accelerate to 75 mph.

Rpms in 3rd gear:

25 mph - 2,000 rpms

35 mph - 3,000 rpms

40 mph - 3,500 rpms

50 mph - 4,500 rpms

60 mph - 5,500 rpms

75 mph - 6,500 rpms

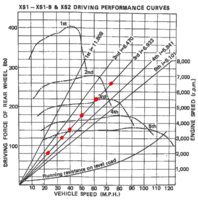

From this chart:

During the acceleration, note any dips in power, report back...

Try this:

At 25mph, in 3rd gear, fully accelerate to 75 mph.

Rpms in 3rd gear:

25 mph - 2,000 rpms

35 mph - 3,000 rpms

40 mph - 3,500 rpms

50 mph - 4,500 rpms

60 mph - 5,500 rpms

75 mph - 6,500 rpms

From this chart:

During the acceleration, note any dips in power, report back...

its unlikely that the rusty exhausts will effect your engine sigificantly but that said if your baffles and wadding have collapsed your silencers could be restricting exhaust flow.

They are so rusty you might as well cut off the rusty tips anyway before they blow off and then clear the silencers out and test with straight through silencers. You can then add some baffles and wadding later

They are so rusty you might as well cut off the rusty tips anyway before they blow off and then clear the silencers out and test with straight through silencers. You can then add some baffles and wadding later

As mentioned, do the slide drop test. Small holes in your diaphragms can exhibit symptoms like you have. The bike will only go so fast because the slides won't lift beyond a certain point. Small holes will allow a small amount of vacuum to be created, enough to partially lift the slides, but they won't lift fully.

Very helpful JMB website TM. Good instructions regarding diaphragms and their fitting. Just how important is the gluing step? Has anyone had to do this to get a tight seal?

Their following link gives loads of information about diaphragms and caring for them e.g. do not use compressed air on the carburetor with the diaphragms fitted and watch out for lean back firing:

http://www.jbmindustries.com/Dimensions.html

Their following link gives loads of information about diaphragms and caring for them e.g. do not use compressed air on the carburetor with the diaphragms fitted and watch out for lean back firing:

http://www.jbmindustries.com/Dimensions.html

Last edited:

I found a bit of a gap, mebbe 2 mm that the replacements don't fill in on the recess of the slide that the hard plastic of the stock diaphragms covered. These were on a junker that I had picked up where the PO had an idea but no clue.

I got that bike running and running well but it would fail after a short ride. The slides were turning, and with the bs38's and their bevel, they can't be turning.

I found some "O" rings to fill the gap but the slides still turned. It was then that I read about the glueing. I glued them along with the O rings in place to fill the gap and so far, so good. Prolly don't need the O rings but Hey, it's done now.

I got that bike running and running well but it would fail after a short ride. The slides were turning, and with the bs38's and their bevel, they can't be turning.

I found some "O" rings to fill the gap but the slides still turned. It was then that I read about the glueing. I glued them along with the O rings in place to fill the gap and so far, so good. Prolly don't need the O rings but Hey, it's done now.

Last edited:

bluesman650

XS650 Enthusiast

I just noticed while looking at the picture of your muffler that you are missing the locknut on your chain adjuster bolt.View attachment 117893 View attachment 117892 Here is the stock exhaust with huge holes rusted in it. Could that be fucking up the way my engine runs?

Yeah, I forgot to grab some. Those are actually just grade 8 bolts I picked up at the hardware store. When I got the bike one side was completely missing the adjuster bolt and the side that had one was missing the locknut. I ground down the ends to a taper with a cheap bastard file and they work well enough. I figured after torquing down the axle it’s not going to move on me. Or am I wrong?

A Gr. 8 bolt would be an SAE size - but your Yamaha is entirely metric....at least, mine are. I'd be cautious about mixing systems on a bike - its too easy to mess up a tapped hole.

Similar threads

- Replies

- 7

- Views

- 719