Hey Guys,

New to the XS family. These forums have been an amazing resource, so thank you for sharing all your knowledge!

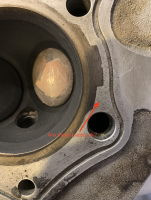

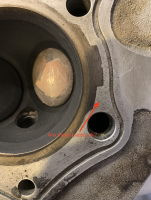

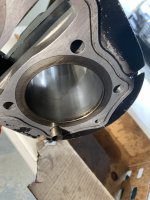

Just completed my first top end tear down on my "new to me" 1980 XS650 and everything looks pretty good.

I'm not coming into this too green, I have past motorcycle experience & I've been trolling this forum, reading as much as I can. Although, this is my first attempt and there are several things I am encountering for the first time. I wanted to share some photos with a much more knowledgeable XS650 community to get some more in-depth advice, insight and best practices in regards to this 40 year old motor.

Thanks in advance for all the help and insight you guys provide!

New to the XS family. These forums have been an amazing resource, so thank you for sharing all your knowledge!

Just completed my first top end tear down on my "new to me" 1980 XS650 and everything looks pretty good.

I'm not coming into this too green, I have past motorcycle experience & I've been trolling this forum, reading as much as I can. Although, this is my first attempt and there are several things I am encountering for the first time. I wanted to share some photos with a much more knowledgeable XS650 community to get some more in-depth advice, insight and best practices in regards to this 40 year old motor.

Thanks in advance for all the help and insight you guys provide!

Last edited:

) reason why i am assuming it could be contributing to this acceleration problem.

) reason why i am assuming it could be contributing to this acceleration problem.