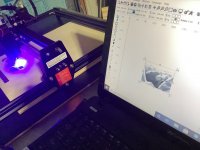

Ok guys, I know I started a build thread that has stalled for a minute and I’m guilty of putting some things off until it cools down outside but nobody ever really explained to me how much time I would have in retirement to pursue things I enjoy doing without schedule constraints. That being said I will get back to the “76 next month on another trip down to hang with pops but in the meantime I have to share my latest toy. I have always been an avid woodworker/furniture maker but used professional basic tools. I decided to up my game so I pulled the trigger on this.

I’m looking at options for software as I’d love to be able to run this with my tablet.

I’m looking at options for software as I’d love to be able to run this with my tablet.

I’m looking at options for software as I’d love to be able to run this with my tablet.

I’m looking at options for software as I’d love to be able to run this with my tablet.