I have measured the pick up hot and cold. Values are somewhat high with 850 ohms hot (2x) and 780 cold. Both wires give the same reading.

Before I left I disconnected the tacho when the bike was running weird, it didn't affect it. I checked the wiring in the headlight, it's fine and undamaged.

I got a modern fuseholder, I can try your suggestion with lower A Fuses.

And regarding the exhaust, I understand but this is electrical for sure. We checked the spark last time it died. We didn't see any sparks, but my friend did get zapped. Maybe it is or was sparking super weak.

Let's see what happens today. At least the view is nice

View attachment 175142

OK New INFO

We checked the spark last time it died. We didn't see any sparks, but my friend did get zapped. Maybe it is or was sparking super weak.

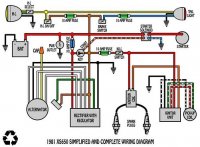

I have had problems with Boyer Bransden at times ..I then sometimes draw separate wires outside the wiring loom

from Battery to ignition parts Coil and Ignition Box Ground to minus on battery

At this point in time I still have those extra ground wires there. did not remove them last time.

+ 12 V Positive can not be there permanently because the box dont withstand that

But I feel it is OK for a short while testing . Fuse there is of course good. But I did not have one.

Later on the + 12 V can go via ignition lock .and wiring loom.

When the spark is there please notice if any difference.Right or Left

Boyer is a Waste spark system so one can move the spark plug caps ..between sides

I dont know if Yamahas box is the same.

I this manner ( Extra wires ) one can ensure that the Ignition parts have the right " Physics " IN

Since 2 boxes been there it is not the box most likely.

....

....