Steve C

XS650 Addict

Feel like my COVID Quarantine build is finally starting to get off the ground! I got this bike almost a year ago. Several projects in front of it are done and sold the bike it's taking the place of...('79 GS 425).

Here's some pics of the bike when I got it...

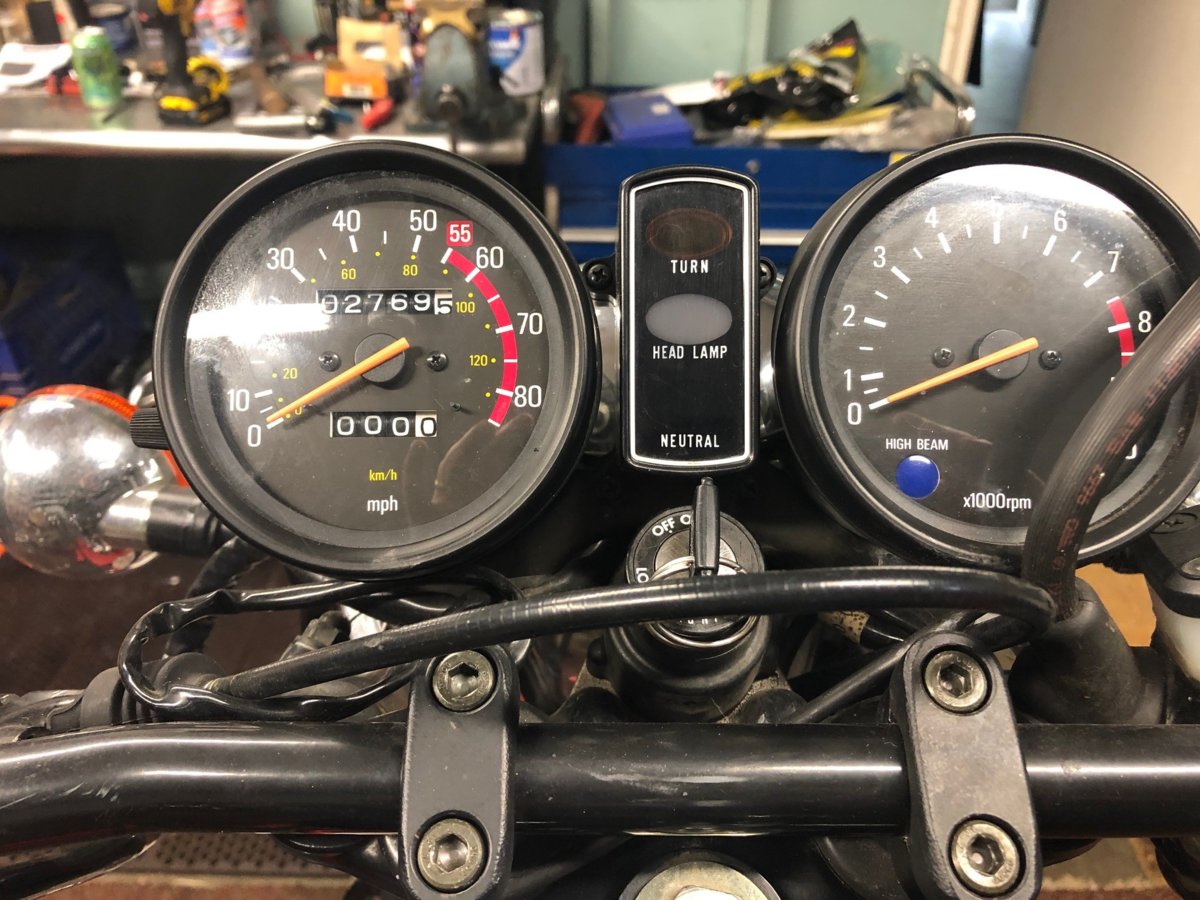

Very clean! clocks say 2770 miles, numbers match, gave $800 for it because....wait for it...Death whine in the engine. Crank alignment WAAAYYY off, Gary Hoos knows. So apart it comes. I love how clean it is, no rust, minimal grime, good starting place. Apologies to the 'Special' fans out there but I wanted to knock some of the ugly off this thing so pulled it down to the frame, cut all the extraneous tabs and escutcheons off. Here's where I'm at with the chassis:

More to come.

Here's some pics of the bike when I got it...

Very clean! clocks say 2770 miles, numbers match, gave $800 for it because....wait for it...Death whine in the engine. Crank alignment WAAAYYY off, Gary Hoos knows. So apart it comes. I love how clean it is, no rust, minimal grime, good starting place. Apologies to the 'Special' fans out there but I wanted to knock some of the ugly off this thing so pulled it down to the frame, cut all the extraneous tabs and escutcheons off. Here's where I'm at with the chassis:

More to come.