I am Carbon

shade tree mechanic

Nice work guys,problem is they all look the same if everybody uses the same pattern!

That okay in my case I have the only xs650 in my town

Nice work guys,problem is they all look the same if everybody uses the same pattern!

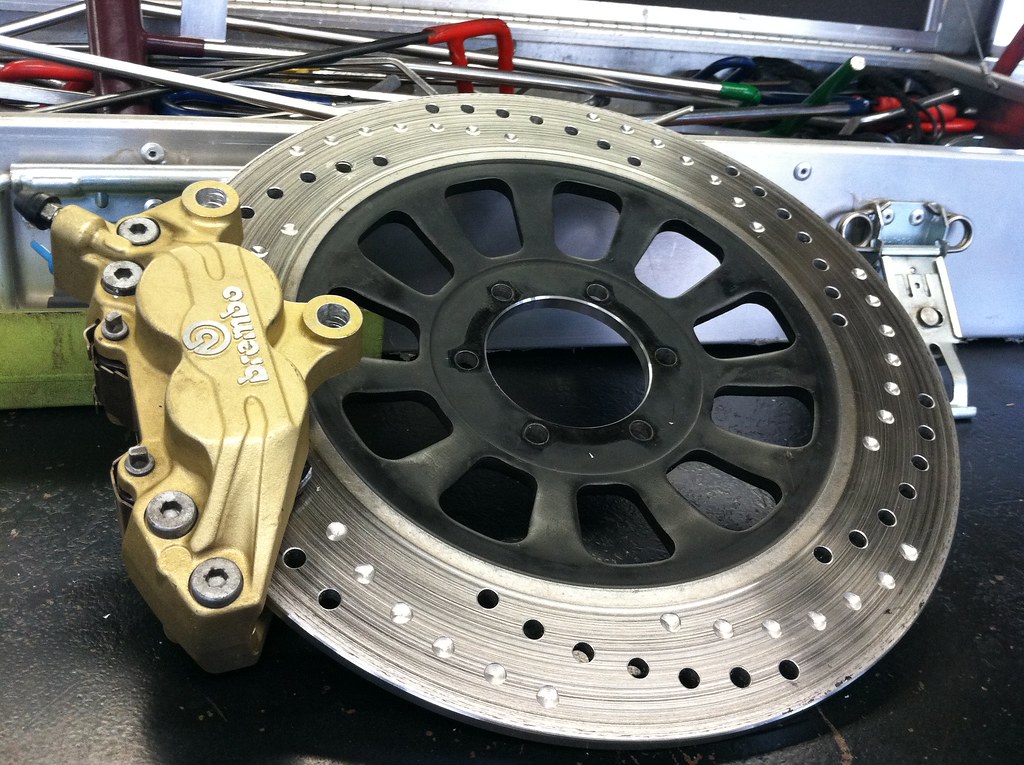

No, you're no idiot, that would be the guy posting fucked up patterns, lol. The one for the front is messed up as well. If you use it, delete the bottom hole in each "swirl" and add one more to the top. If you don't, you'll end up with a FUBAR'd rotor like Carbon's in post #30. That bottom hole is off the pad's swept area and therefore useless. The missing top hole means the entire swept area will not get drilled.

The patterns aren't fucked up.. I figured you could probably handle using scissors to trim where needed to have them line up.. seems everyone else that used the patterns could figure it out just as easy. The patterns worked perfectly for myself, posted them as a guide.. I'm sure a little COMMON sense in using them will help.

Used pretty much the same method. I used the depth gauge on my drill press to make the dimples.....

Untitled by Matt Francosky, on Flickr

p!nK

Hi Kent,My bad. I could have sworn they were the same diameter.

Kent