Just a quick rambling outline of how I raked mine back in '74.

Strongly encourage the welders and frame builders here to chime-in and crotique this method.

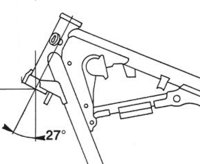

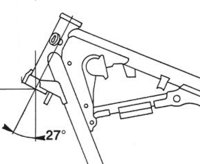

Starting with a side view of a standard frame.

The frame gusseting will have to be removed to do this method.

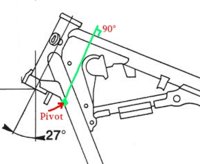

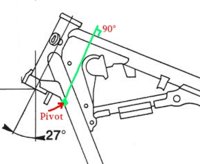

Draw a line perpendicular to the backbone thru to the downtubes.

Where this line meets the front of the downtubes will be the pivot point for the rake angle.

Depending on the amount of additional rake, and material removal, this needs to be planned carefully.

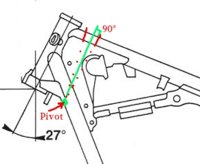

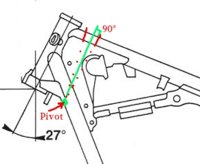

The idea here is to cut the backtube equally from both sides of the centerline, so that the ends will align after bending, to make a non-jogged butt-joint.

I wanted to be as close to the neck as possible, so had to calculate the sine of half the angle to find a suitable setback distance.

I wanted a total rake of 45°. Stock rake is 27°, so needed to cut-out 18° pie sections, 9° either side of the centerline.

The downtubes will also be cut as pie-sections, centered on their perpendicular line.

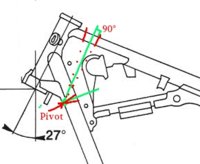

The cut lines are shown in red.

Do not cut all the way through. The front of the downtubes need to remain uncut.

This is the pivot point for the rake job, and retains strength in that area.

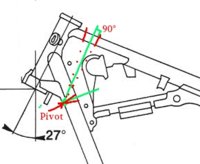

After cutting, chamfer the edges for welding. Tube slugging is recommended.

I fashioned a short piece of tubing that I could fit thru the pie-cut and slid forward into the neck side of the backbone.

Slide a pipe through the steering neck, lash the top of that pipe to a rear section of the frame.

Heat the pivot points of the downtubes and tighten the lashing, pulling the pie-cut joints together.

Then weld the joints. I used chrome-moly rod back then, to match the metalurgy of the frame tubes.

And, this was the final result:

More info:

http://www.baycitydesign.com/xs650/

http://www.xs650.com/threads/newby-chopping-a-72.26419/

http://www.xs650.com/media/raking-the-neck.5552/