Hello my fellow restoration addicts. This article will cover the process involved in re facing your old, faded and cracked speedometer and tachometer dial faces with new reproduction decals. I will not be covering how to disassemble your gauges because that has already been covered in my other thread. Starting here at post #162 The instructions are pretty comprehensive, with a most excellent addition from 2M.

http://www.xs650.com/threads/mailman’s-xs2-a-sympathetic-restoration.51520/page-9

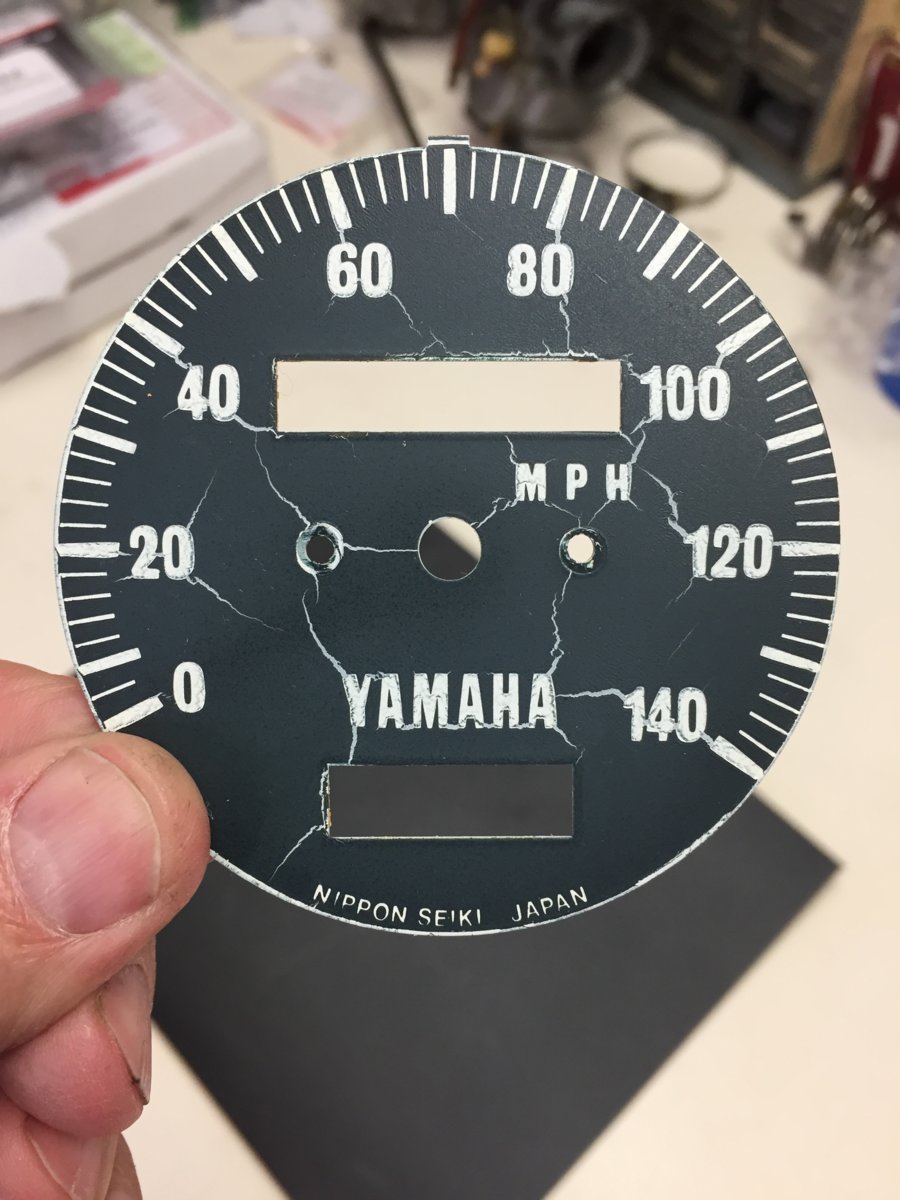

So this is what I’m starting with,

The original gauge face is silk screened and the paint has dried and shrank and it just looks nasty.

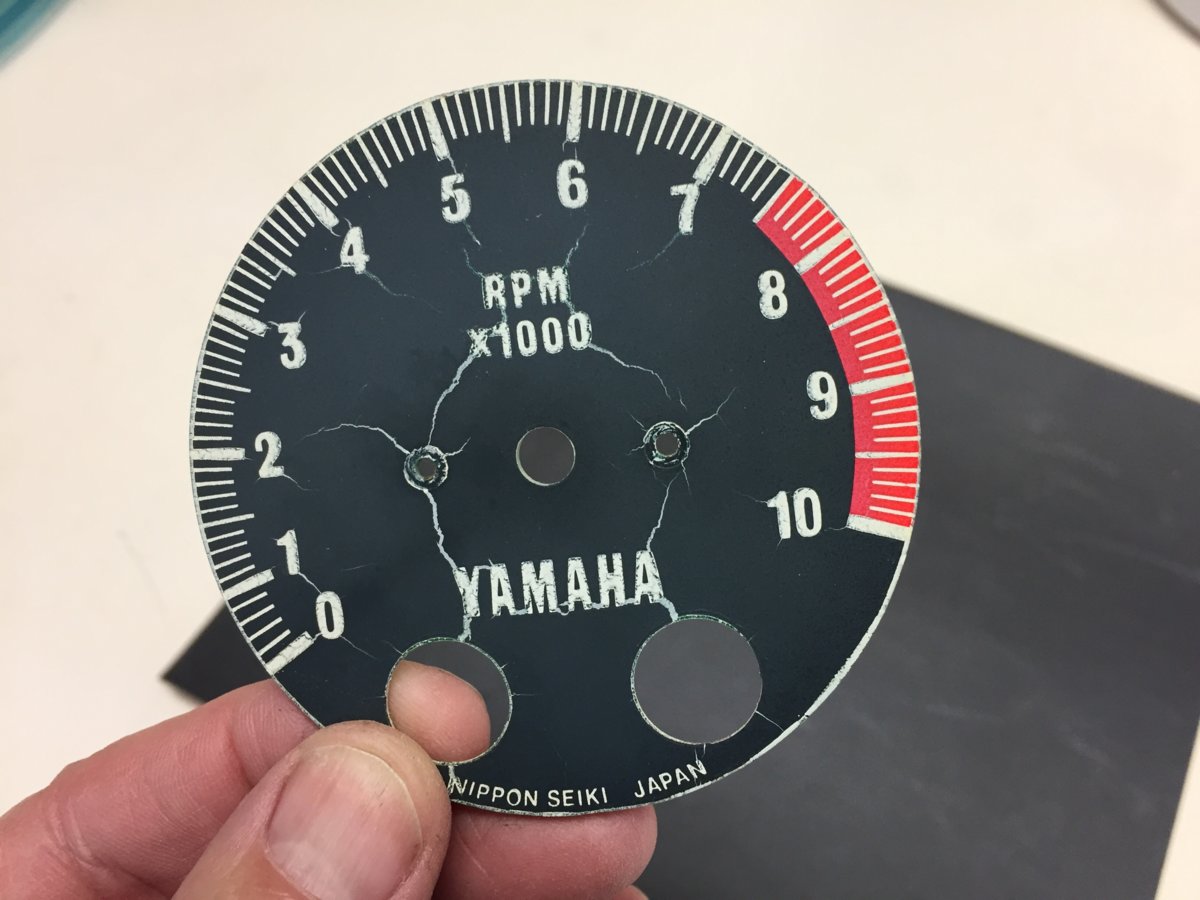

After disassembling the gauges here are the faces.

Note that the chrome bezels around all of the openings have already been removed. Now in order to apply the new decals, the old paint must be removed. This is best accomplished by wet sanding. I did the first step with 400 grit wet sandpaper laid on a flat surface and with a liquid dish soap added.

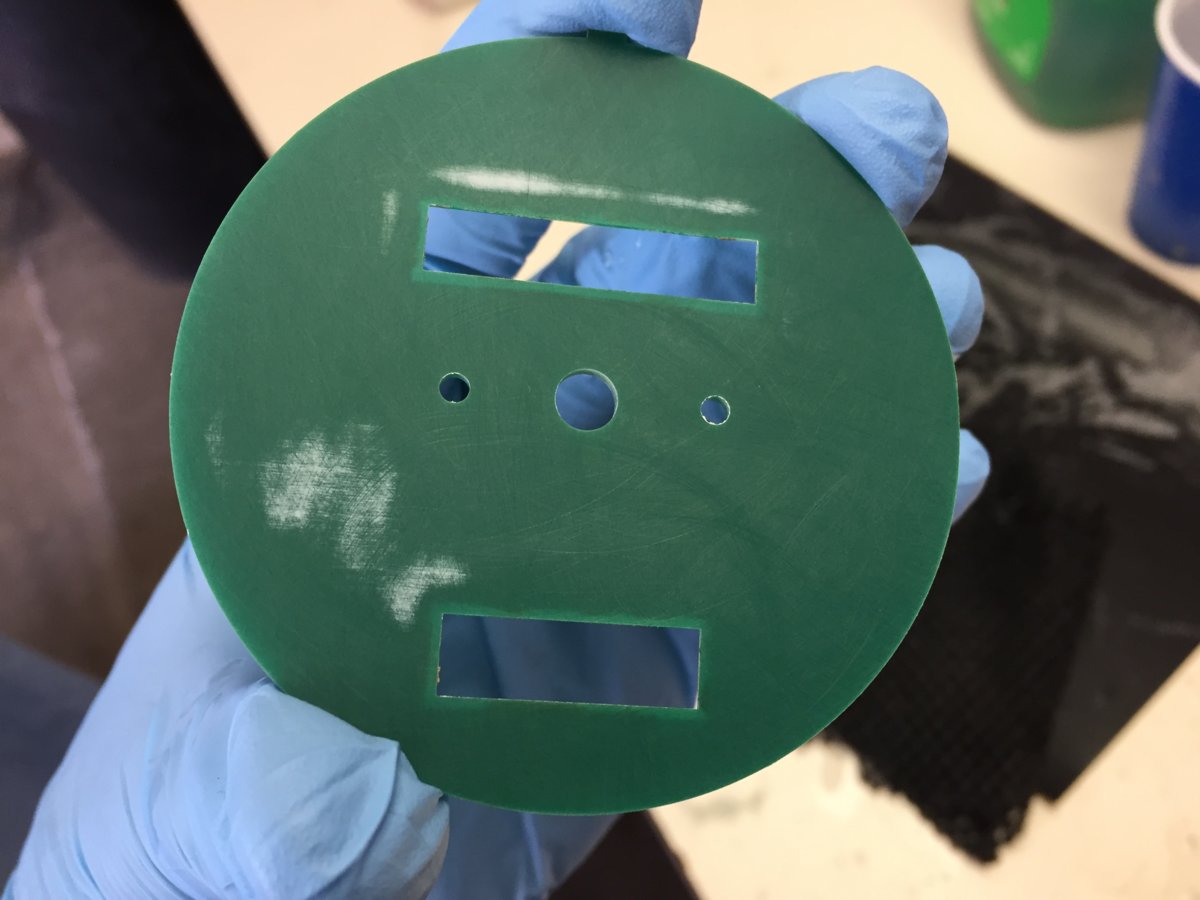

Here are the initial results with 98% of the paint removed.

You can see a lot of scratch marks and we want a smoother surface before applying our decals so I did it again with 1000 grit wet sandpaper. Now we are ready to apply the decals. I got these decals from Diablo Cycle / Reproduction Decals and they are of a high quality for a reasonable price. Throw these guys some business!

http://www.diablocycle.com/search.php?mode=search&page=1

Now on to the application. Here is my set up ready to go. My two decals , my clean gauge faces, a plastic credit card and a micro fiber cloth to work out the bubbles.

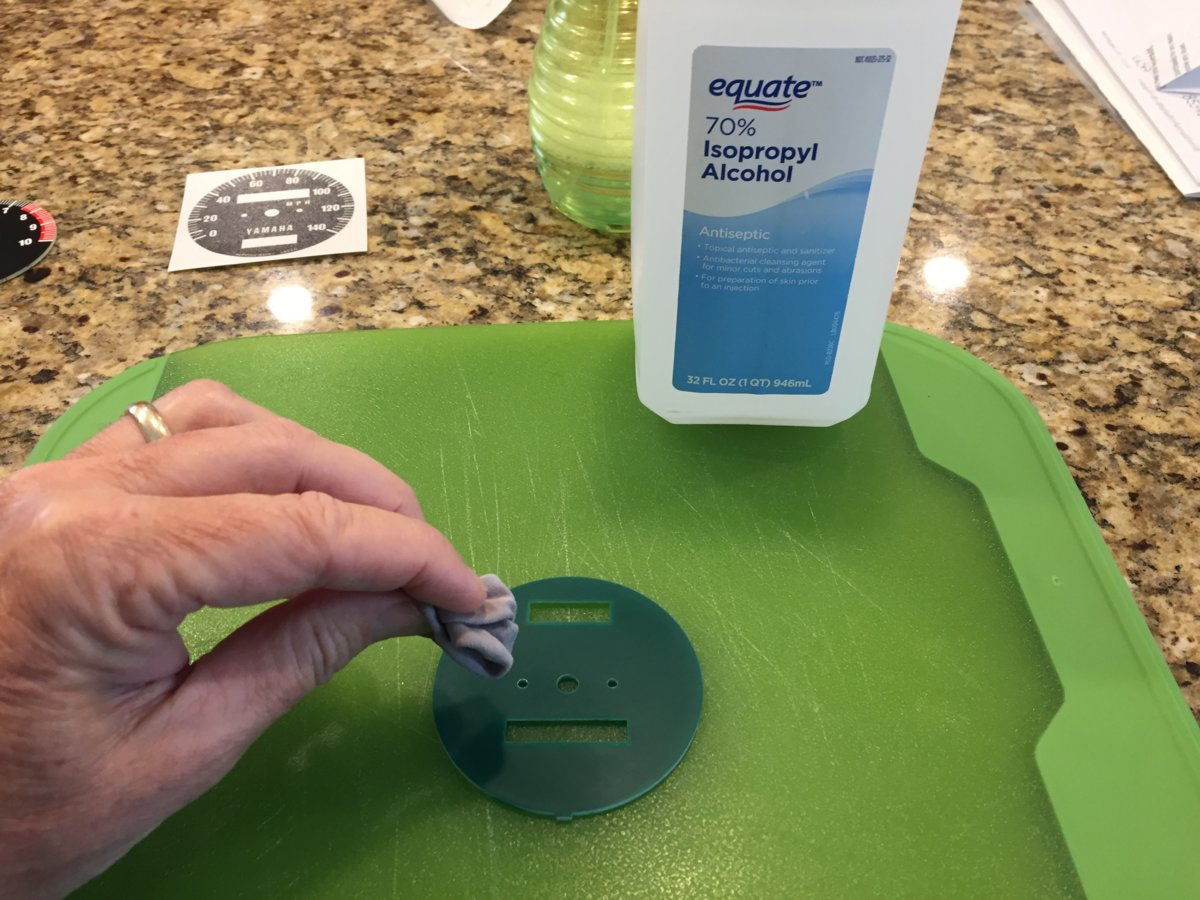

First clean the gauge faces thoroughly with alcohol and let dry.

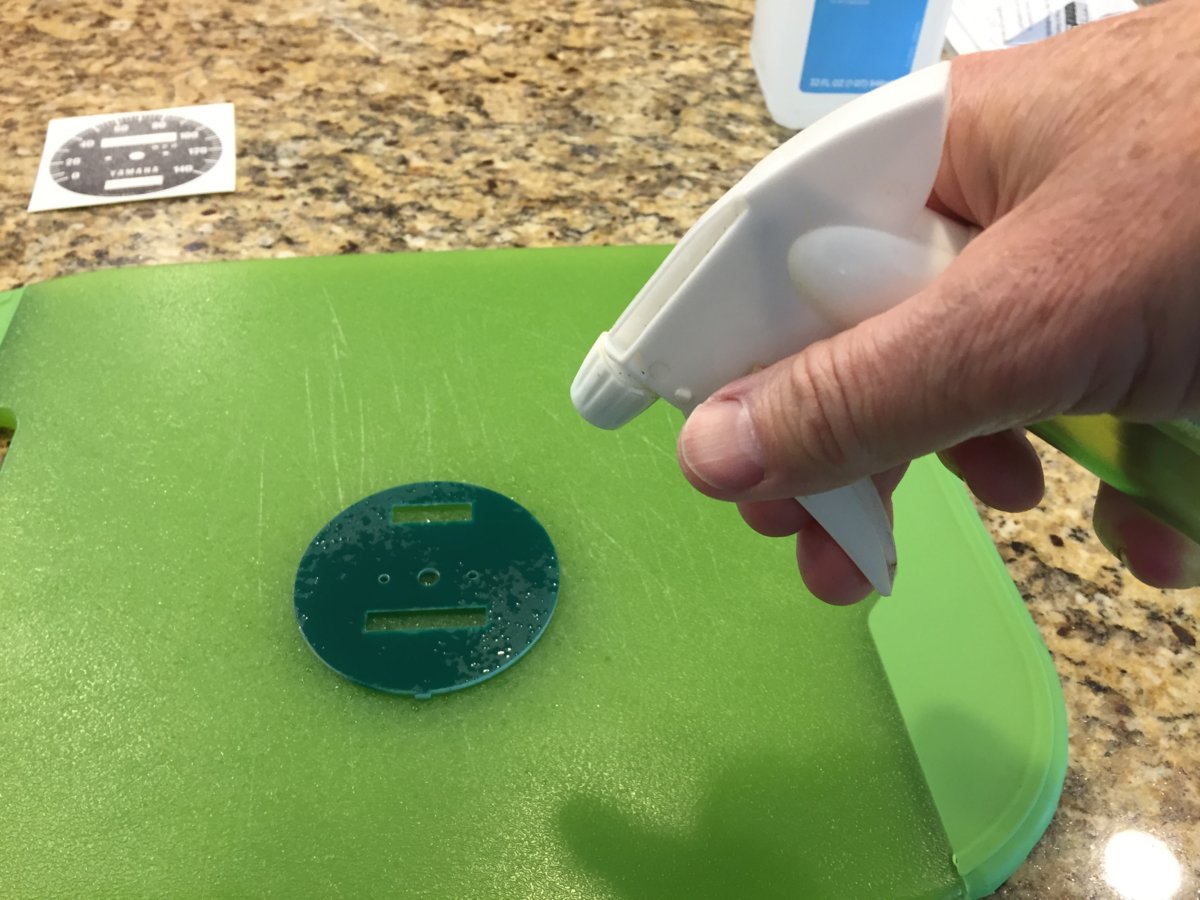

Then have a small spray bottle with some water and a single drop of dish soap in it. This will allow you to lift and reposition the decal. If you have ever applied a screen protector on an electronic device the method is similar. Make sure you have washed your hands and your fingertips are free of oils. Then wet the dial faces.

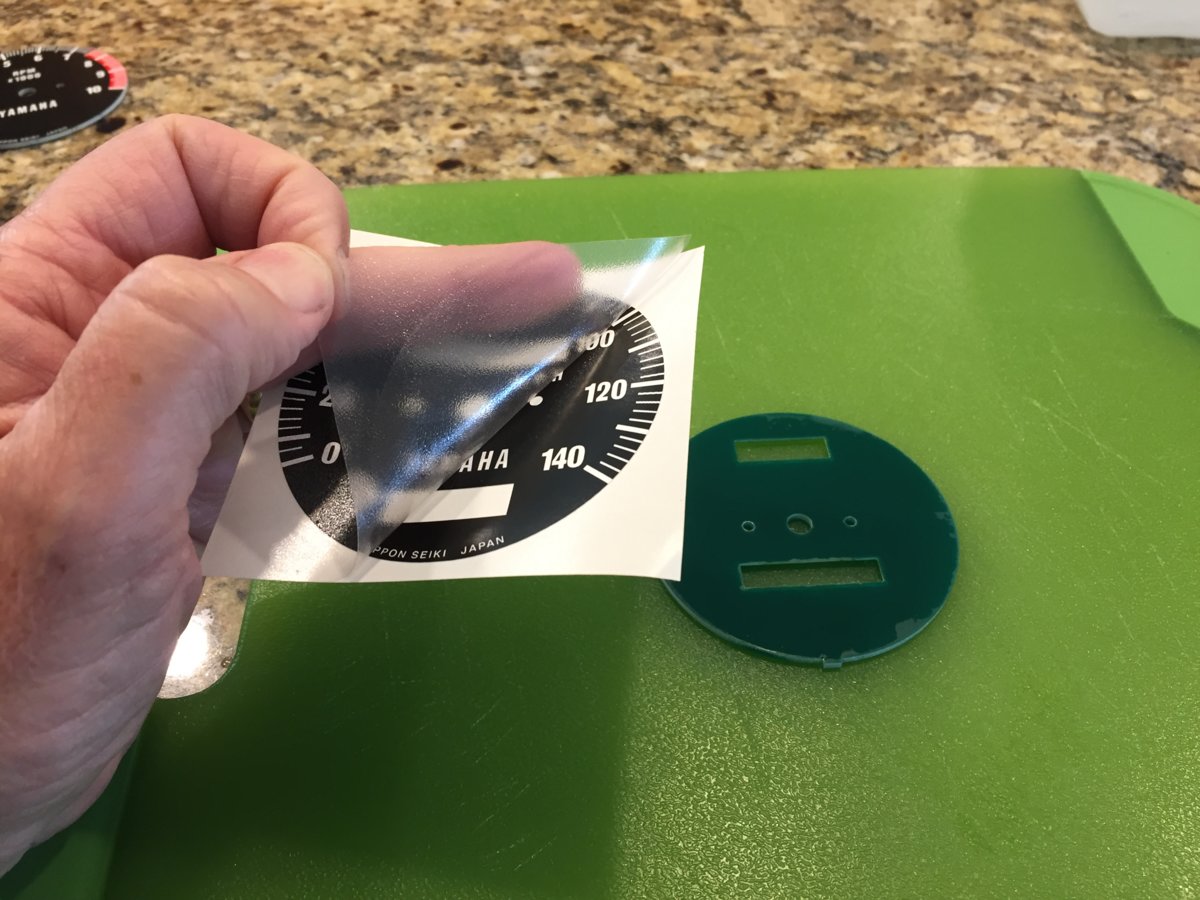

Peel the protective cover from the decal.

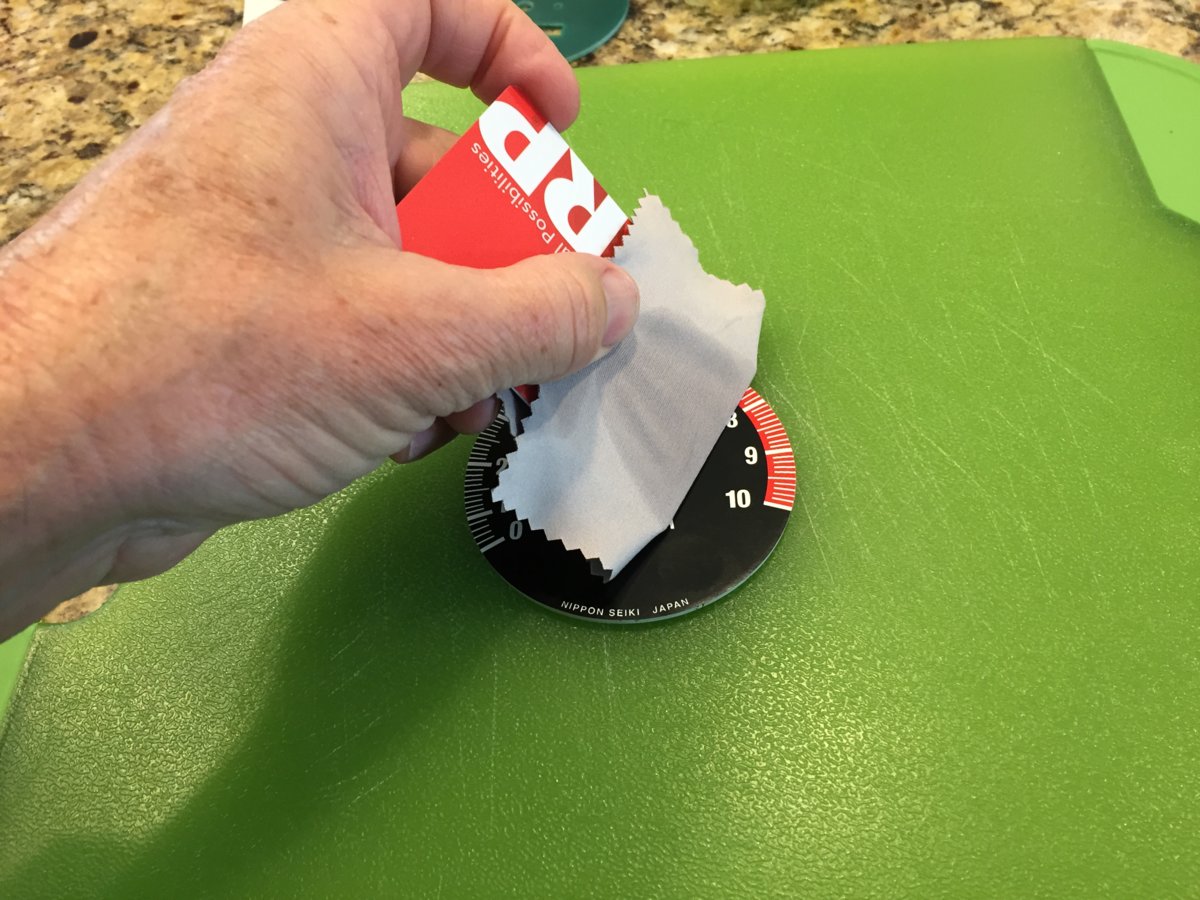

And then carefully peel the decal from the paper back and align it on your dial face. Once you’ve done that, take your credit card covered with a micro fiber cloth (so you don’t scratch the decal ) and work any water bubbles towards the edges.

Beautiful!

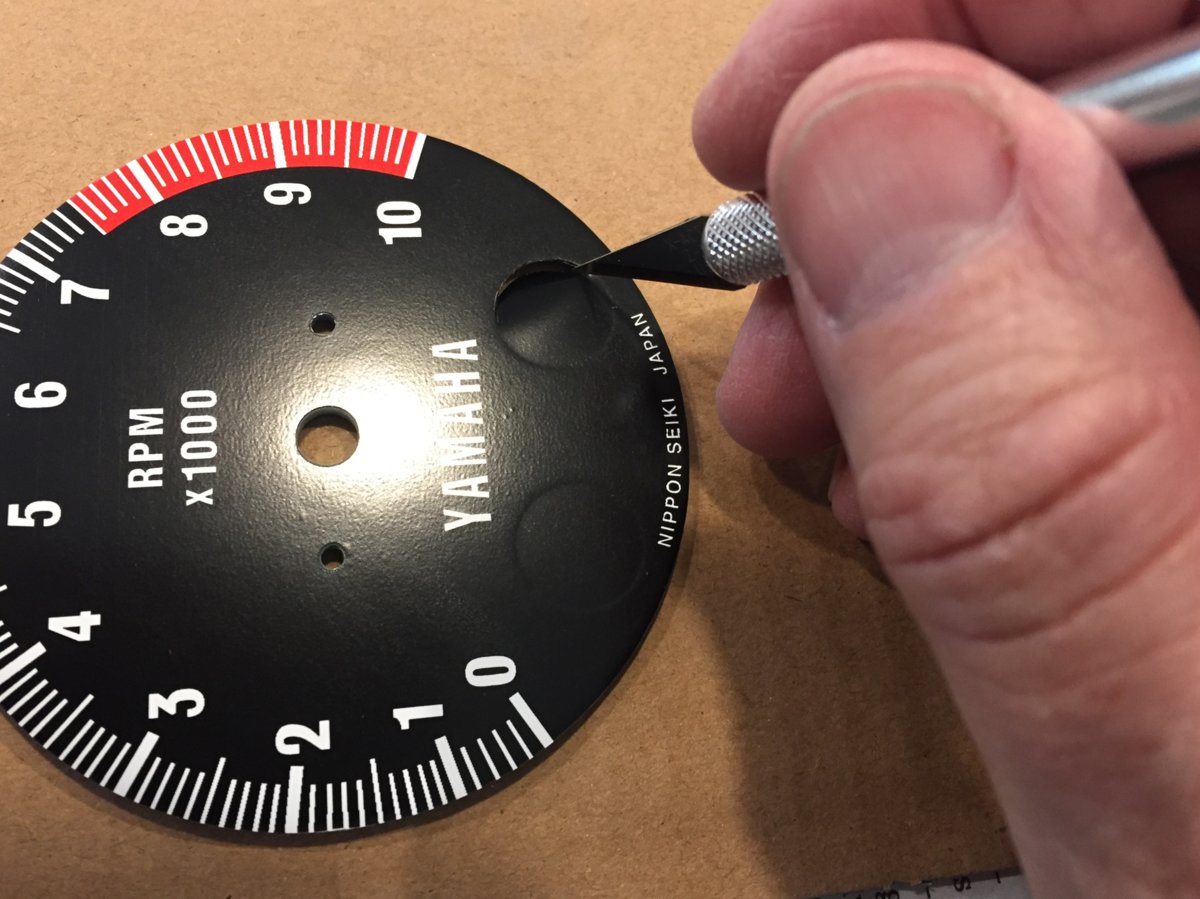

Now the tachometer decal requires that you cut the indicator light openings yourself. That is easily accomplished with an exacto knife.

A little before and after.

Re install the dial faces on your instruments, using a small amount of locktite on the threads. Note: Be careful to tighten these gently , so your screw head does not twist and lift your decal.

You could also add tiny black flat washers under your mounting screws to protect the decals from lifting.

Press your indicator needle back on, clean the glass, and then crimp the bezel back on to your instrument. Being sure to cover your pliers with tape so you don’t scratch anything.

Now admire the results!

They came out extremely nice! I could not be happier!

I would like to thank 2M for his invaluable assistance on this project. I consider his article on restoring gauges to be required reading if you are contemplating opening these gauges up.

http://www.xs650.com/threads/early-model-70-71-instrument-rebuild-rejuvenation.31305/

Thanks for looking, I hope this might help anyone who has thought of doing this job.

Bob

http://www.xs650.com/threads/mailman’s-xs2-a-sympathetic-restoration.51520/page-9

So this is what I’m starting with,

The original gauge face is silk screened and the paint has dried and shrank and it just looks nasty.

After disassembling the gauges here are the faces.

Note that the chrome bezels around all of the openings have already been removed. Now in order to apply the new decals, the old paint must be removed. This is best accomplished by wet sanding. I did the first step with 400 grit wet sandpaper laid on a flat surface and with a liquid dish soap added.

Here are the initial results with 98% of the paint removed.

You can see a lot of scratch marks and we want a smoother surface before applying our decals so I did it again with 1000 grit wet sandpaper. Now we are ready to apply the decals. I got these decals from Diablo Cycle / Reproduction Decals and they are of a high quality for a reasonable price. Throw these guys some business!

http://www.diablocycle.com/search.php?mode=search&page=1

Now on to the application. Here is my set up ready to go. My two decals , my clean gauge faces, a plastic credit card and a micro fiber cloth to work out the bubbles.

First clean the gauge faces thoroughly with alcohol and let dry.

Then have a small spray bottle with some water and a single drop of dish soap in it. This will allow you to lift and reposition the decal. If you have ever applied a screen protector on an electronic device the method is similar. Make sure you have washed your hands and your fingertips are free of oils. Then wet the dial faces.

Peel the protective cover from the decal.

And then carefully peel the decal from the paper back and align it on your dial face. Once you’ve done that, take your credit card covered with a micro fiber cloth (so you don’t scratch the decal ) and work any water bubbles towards the edges.

Beautiful!

Now the tachometer decal requires that you cut the indicator light openings yourself. That is easily accomplished with an exacto knife.

A little before and after.

Re install the dial faces on your instruments, using a small amount of locktite on the threads. Note: Be careful to tighten these gently , so your screw head does not twist and lift your decal.

You could also add tiny black flat washers under your mounting screws to protect the decals from lifting.

Press your indicator needle back on, clean the glass, and then crimp the bezel back on to your instrument. Being sure to cover your pliers with tape so you don’t scratch anything.

Now admire the results!

They came out extremely nice! I could not be happier!

I would like to thank 2M for his invaluable assistance on this project. I consider his article on restoring gauges to be required reading if you are contemplating opening these gauges up.

http://www.xs650.com/threads/early-model-70-71-instrument-rebuild-rejuvenation.31305/

Thanks for looking, I hope this might help anyone who has thought of doing this job.

Bob

Last edited: