Now you need to make a pedestal mount to take full advantage of the 360° rotation. It never ends does it....Stripped, cleaned, reassembled. I'll let it dry good and brush on a coat of gray enamel.

Was surprised how good it is, not a sloppy old beater, tight and smooth, either run by a careful operator or saw little use?

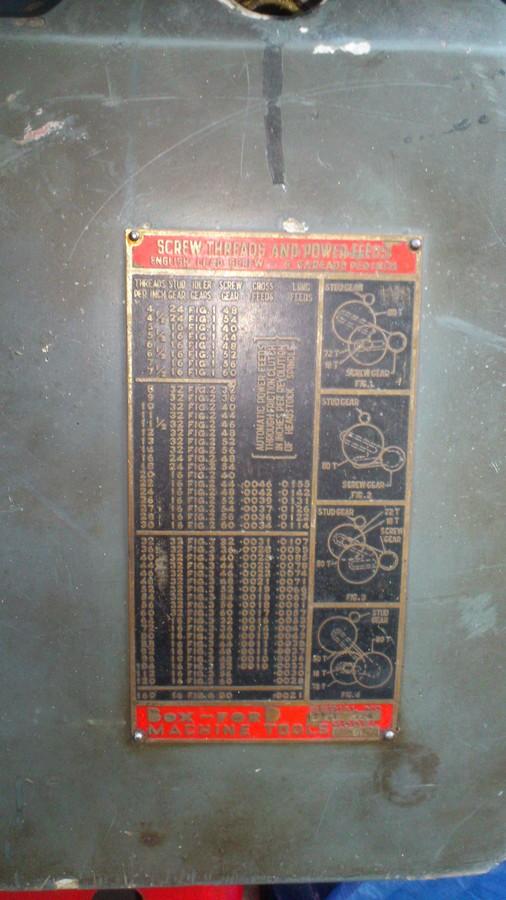

View attachment 178853 View attachment 178854 View attachment 178855

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it my turn? Anything to do with lathes, mills and other shop tools

Sacaps

XS650 Member

Thanks in advance.

Stephen

Sounds like your half nuts are disengaged in the saddle.

Does the hand wheel move the carriage?

Not sure about that particular machine but on my Logan the half nuts are only engaged during threading ops. Hand wheel drives a gear up and down the rack gear on the bottom of the front way. Power feed is driven by a feather key on the lead screw, through a clutch.

Not sure about that particular machine but on my Logan the half nuts are only engaged during threading ops. Hand wheel drives a gear up and down the rack gear on the bottom of the front way. Power feed is driven by a feather key on the lead screw, through a clutch.

Yer right Beags... Not sue what I was thinkin'...the half nuts are only engaged during threading ops.

The hand wheel is disengaged when feed is selected so when you deselect feed, the hand wheel must be "re-engaged"

Whats the model number?

Whats the model number?

Sacaps

XS650 Member

Took the machine apart today.(it's a Standard Modern utillathe 10").

The only thing I found was the rack hanging from the bed was loose. Not sure what else I'm lookin for but it needed cleaning anyway.im also not sure how to proceed any further. Have to think on it for a while.

Sacaps

XS650 Member

Thanks Gary. Standard Modern has a similar manual on their website.

Item 51 on page 22, saddle clamp. Is this used to add drag to the carriage for this very reason?

Item 51 on page 22, saddle clamp. Is this used to add drag to the carriage for this very reason?

Yeah I'm just a hacker but locking the carriage for facing operations, a good practice. Set depth of cut with the compound.

I'd already removed the "tickler" (tenth's dial) . Two tenths radial and axial initially. At least a tenth was surface imperfections or the back of the chuck to spindle shoulder register. A little more dedicated cleaning got it to a wiggle both ways. Couldn't be happier.

It's here, at last.

A flurry of activity over the past week and suddenly it arrived at 7am.

Unloading it from the delivery van was a hoot; no lifting gear and only an old hospital bed to act as a kind of loading platform.

Got it off and sheeted it up until my engine crane arrives, then I can move it into the workshop.

The driver was run off his feet, delivering items all over Ireland this weekend and back and forth again before Xmas, as people try to get stuff brought over before the stupidity of B wrecks it takes place.

For those who missed my earlier post, it's a Boxford model A, a clone of the South Bend 9".

A flurry of activity over the past week and suddenly it arrived at 7am.

Unloading it from the delivery van was a hoot; no lifting gear and only an old hospital bed to act as a kind of loading platform.

Got it off and sheeted it up until my engine crane arrives, then I can move it into the workshop.

The driver was run off his feet, delivering items all over Ireland this weekend and back and forth again before Xmas, as people try to get stuff brought over before the stupidity of B wrecks it takes place.

For those who missed my earlier post, it's a Boxford model A, a clone of the South Bend 9".

Huge amount of info on the interwebz for this clone. You'll be fine.

If not, just ask

If not, just ask

Okay where were we ?

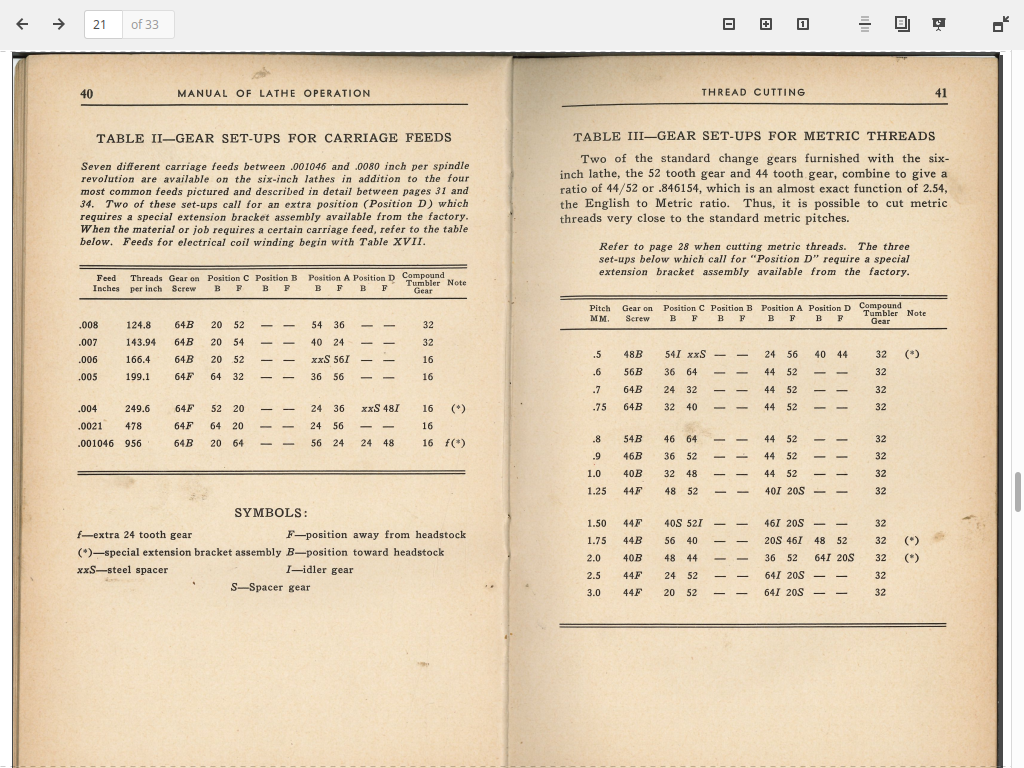

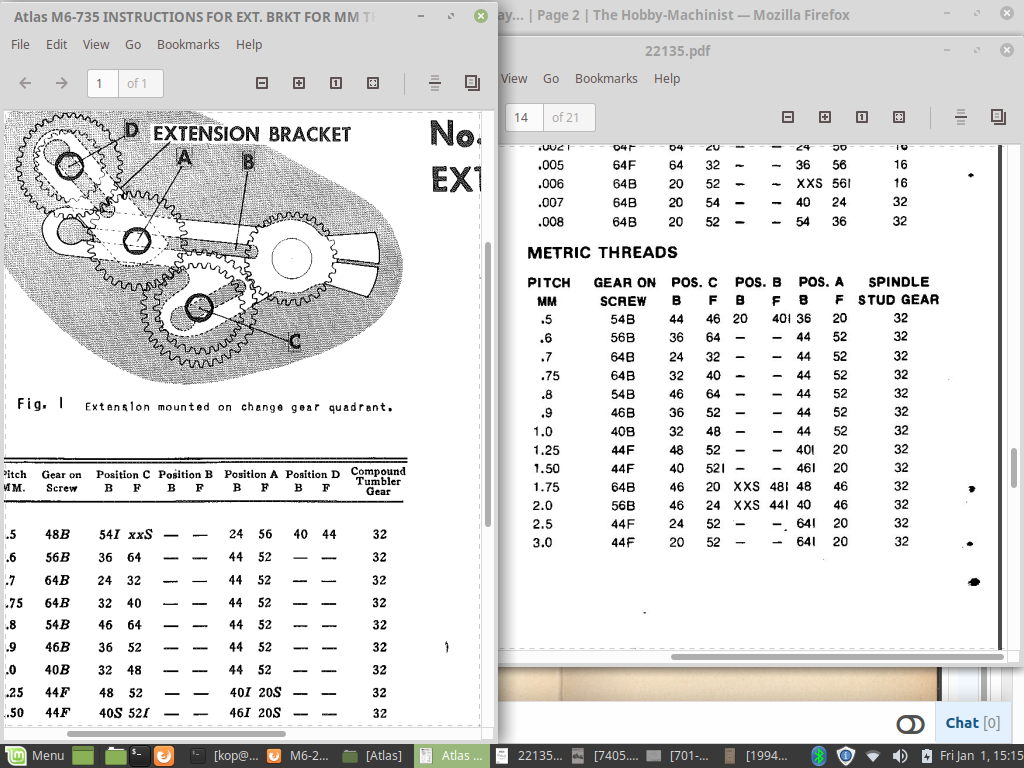

This is the earliest (okay nearly so) reference I find to an extension bracket for metric threads.

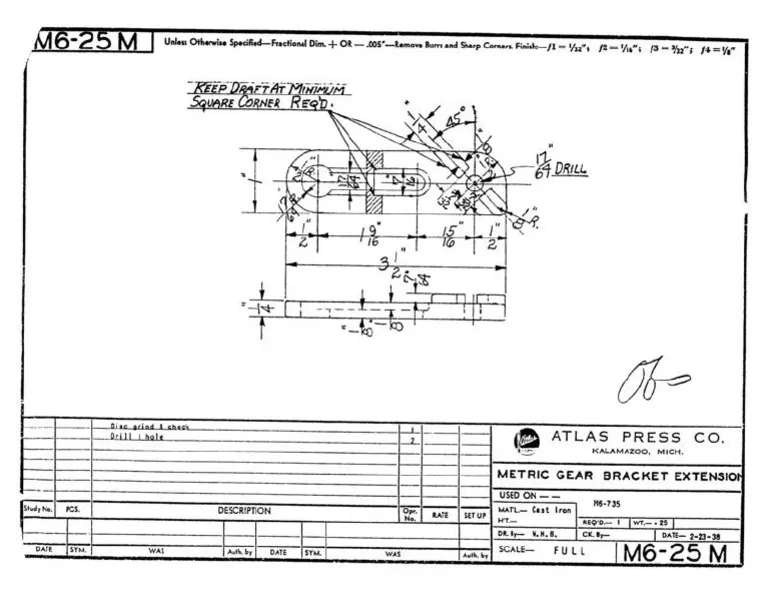

On the left is the instructions for the extension bracket and the M6-25 bracket for the 618 lathe identifying position "D".

On the right is the chart for the Mk II identifying position "B" but making no mention of the extension bracket.

Above is a drawing I scrounged from the webz. A cleaner copy is available from

https://www.hobby-machinist.com/

I'll have to sit down and do the complete ratio/conversion myself just to verify I'm close to 50.8 TPI,

or as close to .5 mm pitch as possible.

details as they happen , film at 11:00

This is the earliest (okay nearly so) reference I find to an extension bracket for metric threads.

On the left is the instructions for the extension bracket and the M6-25 bracket for the 618 lathe identifying position "D".

On the right is the chart for the Mk II identifying position "B" but making no mention of the extension bracket.

Above is a drawing I scrounged from the webz. A cleaner copy is available from

https://www.hobby-machinist.com/

I'll have to sit down and do the complete ratio/conversion myself just to verify I'm close to 50.8 TPI,

or as close to .5 mm pitch as possible.

details as they happen , film at 11:00

The bigger atlas has 3 fingers on the gear holder, but a full set of gears leaves you a few short for metric. I ended up having to buy a couple gears and an arbor for my 10" atlas to do metric. I could wish for a quick change, but since my home machines are just for hobby it's fine.

I did just order a gas heater for the garage. That way I can get out there and not freeze.

I did just order a gas heater for the garage. That way I can get out there and not freeze.

Similar threads

- Replies

- 9

- Views

- 898

- Replies

- 24

- Views

- 7K

m Today on the VFT.

m Today on the VFT.