-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it my turn? Anything to do with lathes, mills and other shop tools

Ryan 79 Nice workshop, and bike how on earth do you keep the workshop so clean?

Beags64 a DR on the mill is very high on my list. Making disc adaptors and such would be so much easier.

gggGary Thanks for the kind words, I have decided to make another filter holder for my tracker seeing as its having a bit of a rehash. For what its worth I don’t think your lawnmower repair is a hack. Its only a lawnmower part.

I have been busy in the workshop this weekend making bits and pieces for a 1970”s XS powered sidecar that a friend is refurbishing. Will post some pictures later.

Beags64 a DR on the mill is very high on my list. Making disc adaptors and such would be so much easier.

gggGary Thanks for the kind words, I have decided to make another filter holder for my tracker seeing as its having a bit of a rehash. For what its worth I don’t think your lawnmower repair is a hack. Its only a lawnmower part.

I have been busy in the workshop this weekend making bits and pieces for a 1970”s XS powered sidecar that a friend is refurbishing. Will post some pictures later.

I have not been too keen on carbide tips because they chip easily when misused and then are difficult to touch up. I have a diamond stone sharpening set and it was not very expensive (£14). I tried my old carbide tools on them and they cut into the carbide like a file into mild steel. I was very surprised how quickly I could refinish my lathe tools. In a couple of minutes I had repaired my favourite parting tool and boring bar.

Howlinwolfxs

XS650 Enthusiast

had to turn down a lathe on trade, due to nowhere to put it

Doing this was a bit scary.

Modified a cart I found at Delaney's the local surplus place extraordinaire.

Rolled into the garage with little problem.

We'll see if there's any issues with it being on the cart, has screw down pads so the casters aren't constantly stressed. Need to wire in it's dedicated VFD and control then finally chips!

Modified a cart I found at Delaney's the local surplus place extraordinaire.

Rolled into the garage with little problem.

We'll see if there's any issues with it being on the cart, has screw down pads so the casters aren't constantly stressed. Need to wire in it's dedicated VFD and control then finally chips!

Cool RR

The millrites are notoriously low at the table, the increased height should suit my 6' 3" better plenty of "head room" once I got it past the garage door.

The millrites are notoriously low at the table, the increased height should suit my 6' 3" better plenty of "head room" once I got it past the garage door.

Slowly gearing up for the 700 four engine build. Will need to machine the RD head gasket recess off the cylinders so we can run RD 400 head gaskets.

I don't know much about flycutters so spent a bit of time reading and had a crack at making one.

Tested it out with some different inserts and it needs another tool holder on the other side (non cutting) to better balance it, I will need to drill and tap some more holes .

Also experimented with speed and feed (manual).

Also on the list of things to make is a head centering tool so the heads can be dowelled, a mandrel for the lathe to hold the RD heads and a may also buy a radius cutter so the compression bowls on the heads can be recut to get the compression back down once the squish is set.

I don't know much about flycutters so spent a bit of time reading and had a crack at making one.

Tested it out with some different inserts and it needs another tool holder on the other side (non cutting) to better balance it, I will need to drill and tap some more holes .

Also experimented with speed and feed (manual).

Also on the list of things to make is a head centering tool so the heads can be dowelled, a mandrel for the lathe to hold the RD heads and a may also buy a radius cutter so the compression bowls on the heads can be recut to get the compression back down once the squish is set.

700 4 2 stroke? I'm intrigued, izzair a thread sumwheres? square, vee, inline, boxer? LOL. Allen is that you?

d'you follow Joe Pieczynski on youtube?

d'you follow Joe Pieczynski on youtube?

gggGary no I am certainly not Allen Millard if that is who you are referring to. He is very inspirational though.

I have seen some of Joe's clips on youtube and find them helpful At the moment I am about to try threading on the lathe so have been watching youtube a lot.

There are a few pics of the 700/4 in this thread on pages 6 and 7

.http://www.xs650.com/threads/two-stroke-memories.50222/page-7

Have been doing a few little bits on it ,exhaust flanges, cutting reeds stuff like that. I am waiting for the brains behind the operation to get some free time so we can crack on and get the crank built and cases welded.

I have seen some of Joe's clips on youtube and find them helpful At the moment I am about to try threading on the lathe so have been watching youtube a lot.

There are a few pics of the 700/4 in this thread on pages 6 and 7

.http://www.xs650.com/threads/two-stroke-memories.50222/page-7

Have been doing a few little bits on it ,exhaust flanges, cutting reeds stuff like that. I am waiting for the brains behind the operation to get some free time so we can crack on and get the crank built and cases welded.

Lindsay G

XS650 Enthusiast

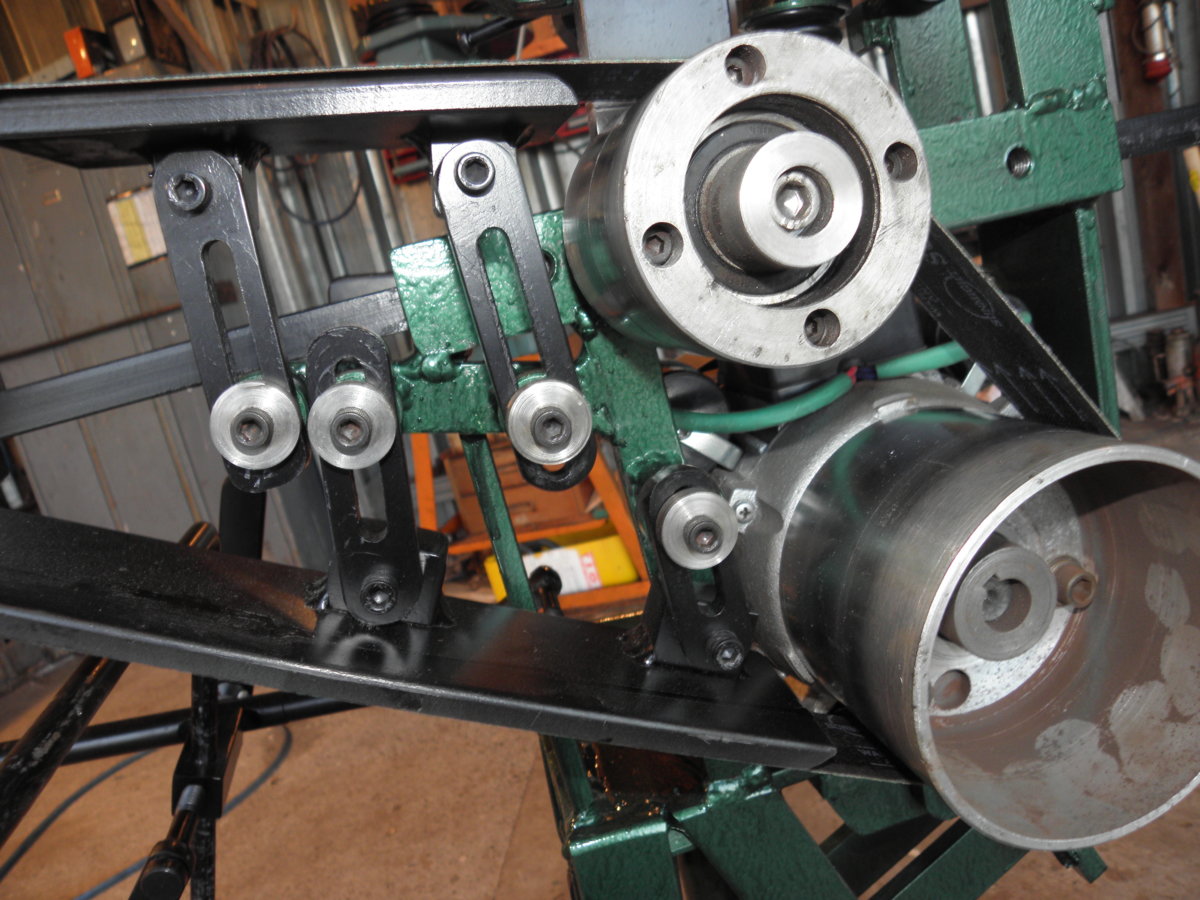

When I bought my mill ( I had owned a small lathe for a couple of years by then) I designed and built this linisher to learn how to set up and use a mill.The linisher takes three different length belts and can be used horizontally or vertically.

Never seen a "linisher" before, nice work there Lindsey!

Linishers are really handy tools to have in the workshop. Lindsay G that one is a beast !

Lindsay G

XS650 Enthusiast

Here's the department of things that rotate. The Colchester lathe turned out to be a bit of a dissapointment. I bought it on an online auction but it couldn't be tested as they didn't have three phase power but as it was only 15 miles away I bought it anyway. If it had been OK it would have been a bargain but it wasn't so its a low priority thing that I'll get onto sometime.

Lindsay G

XS650 Enthusiast

Hope I'm not violating the spirit of the thread but here's the entertainment corner and the heater I bought last month when the first cold snap came through.

Back on page 6 post number 112 I showed a photo of the start of a set of triple clamps a mate was making on my mill. Forward to today and they are finally finished.

WOW - very nice Signal - beautiful machining!

What a great looking shop you’ve got there Lindsey.

What a great looking shop you’ve got there Lindsey.

Last edited:

Not my work my friend designed and made it.

Similar threads

- Replies

- 9

- Views

- 910

- Replies

- 24

- Views

- 7K