Very snazz!!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jim's 1980 SG Miss September

- Thread starter Jim

- Start date

What a nice score! Your bike deserves a new seat!

Tip of the day, sniff the new seats, not the old seats. Butt, whatever makes you happy.

Scott

Scott

......not the old seats.

Just had a quick visit from Phil (@halfmile )..... and he was bearing gifts.

A brand new, never been used seat.

View attachment 123042

View attachment 123043

View attachment 123044

I'm pretty sure it's for an 80 and newer Special. Anybody have a good idea on exactly what year?

Hmmm.... even has that new upholstery smell.

Mighty purdy there Jimbo.

GW

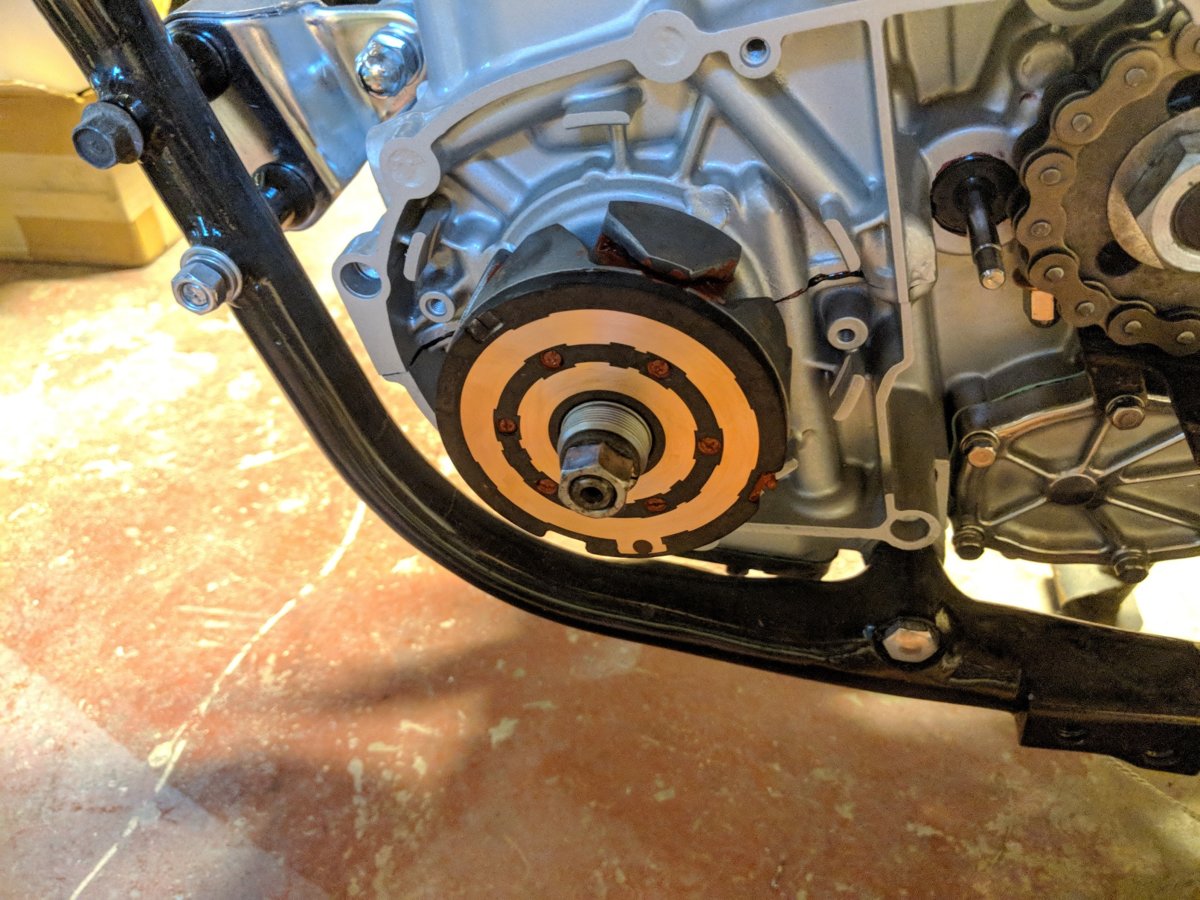

Freshly rewound rotor is installed....

Now where the hell did I put the stator.....

Now where the hell did I put the stator.....

Tip of the day, sniff the new seats, not the old seats. Butt, whatever makes you happy.

Scott

That depends on who's been riding it...

Jim, where did you find a NOS engine to stick the rotor on? Very nice contrast against that fresh looking frame too. Questions: Are the copper rings only held on by the 6 screws or is glue/shellac used on the backing plate?

Just the screws Paul.

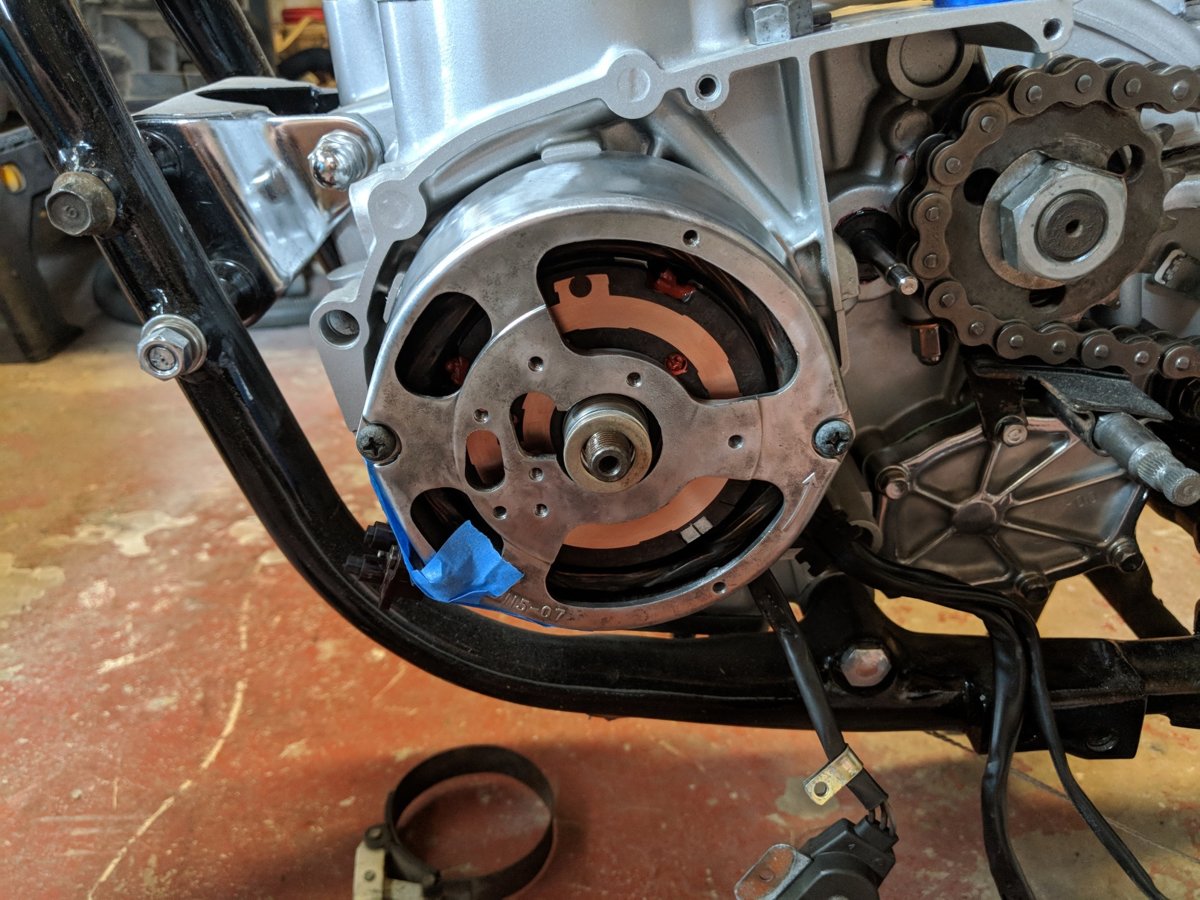

Found the Stator...

I'm sure there was a reason I stuck it in a box...... in the basement.... under 2 other cardboard boxes..... I'm sure there was....

About halfway through cleaning it up, I realized I didn't have any before pics. Trust me the corrosion was horrible.....

A little wire wheel and rolok disk work, a scrub in the stoddard tank.... and new stainless hardware.....

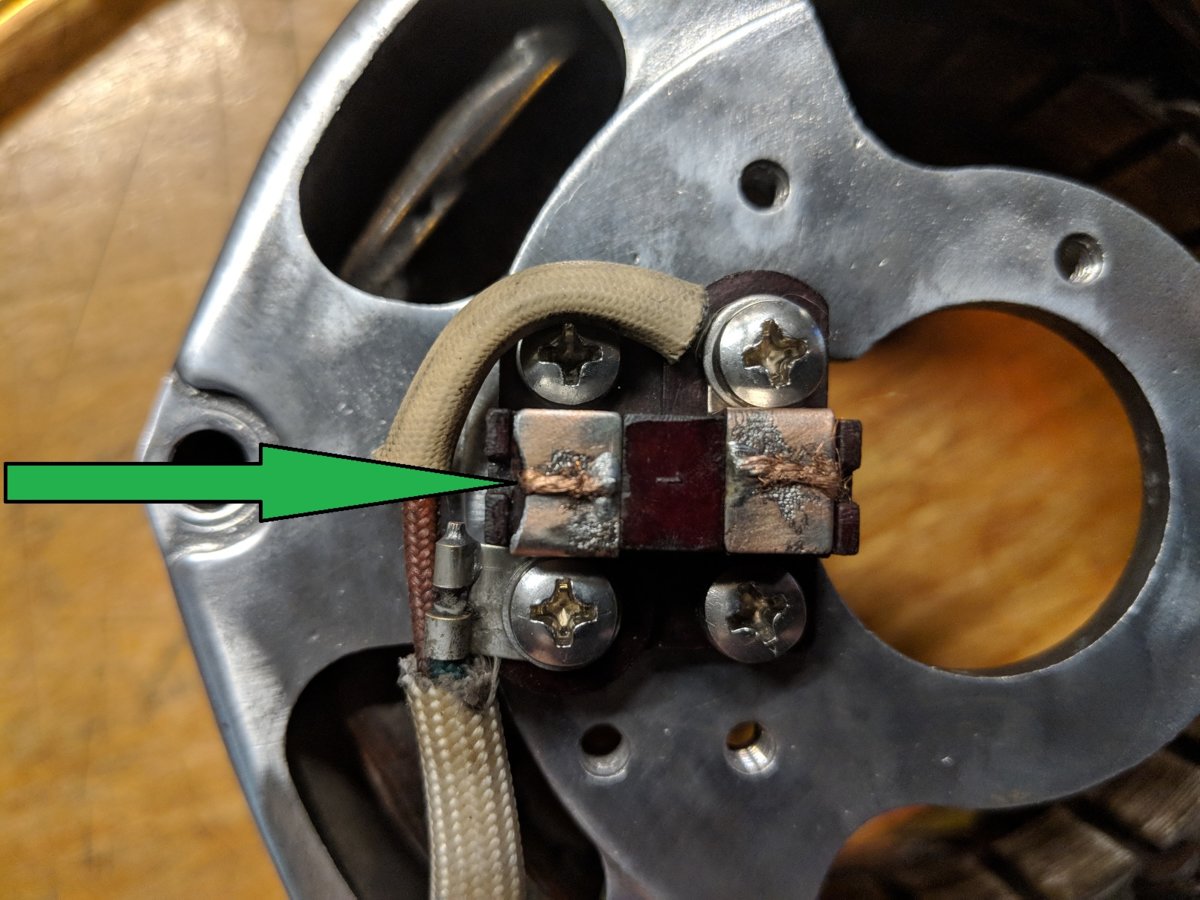

Outer brush sticks out 'bout 1/8". Was hoping to find some NOS ones on Ebay.... no joy. So..... whats the best choice for aftermarkets?

Anybody?

I'm sure there was a reason I stuck it in a box...... in the basement.... under 2 other cardboard boxes..... I'm sure there was....

About halfway through cleaning it up, I realized I didn't have any before pics. Trust me the corrosion was horrible.....

A little wire wheel and rolok disk work, a scrub in the stoddard tank.... and new stainless hardware.....

Outer brush sticks out 'bout 1/8". Was hoping to find some NOS ones on Ebay.... no joy. So..... whats the best choice for aftermarkets?

Anybody?

Are you talking about the brush bracket?

http://www.xs650.com/threads/mikes-alternator-brushes-product-warning.47536/

http://www.xs650.com/threads/mikes-alternator-brushes-product-warning.47536/

NOS stator also??? Amazing transformation!

That's a great clean-up job, Jim. Did it look like this 'before'?

Barnacles, my friend. And didn't I read somewhere, someone making brushes with old battery carbons? Like out of a 'D' cell? I get the "grinding to size" part, but how to attach to the wire to the carbon itself? Have you ever heard of such a thing, or is it shade-tree quackery?

Barnacles, my friend. And didn't I read somewhere, someone making brushes with old battery carbons? Like out of a 'D' cell? I get the "grinding to size" part, but how to attach to the wire to the carbon itself? Have you ever heard of such a thing, or is it shade-tree quackery?

It wasn't quiet that bad Tebo, but yeah..... pretty close.

Never heard of makin' your own. No idea how you'd attach the wire.

Never heard of makin' your own. No idea how you'd attach the wire.

Bracket (or housing) is fine. I just need the brushes.Are you talking about the brush bracket?

Thanks Paul.NOS stator also??? Amazing transformation!

It wasn't quiet that bad Tebo, but yeah..... pretty close.

Never heard of makin' your own. No idea how you'd attach the wire.

How about this:

https://www.sciplus.com/conductive-...MInPfBnsnb3AIVGXZeCh3C3Q-LEAkYASABEgL_rfD_BwE

Or:

https://semicro.org/products/conduc...MInPfBnsnb3AIVGXZeCh3C3Q-LEAkYBiABEgIJIPD_BwE

Think I buy a few different aftermarket brushes before spending over $52.00 on a couple tubes of glue!

N.O.S. brushes pop up often on eBay, just keep looking. I laid in several spare sets already and for little, if any more than what the repops cost. Keep in mind that the '79 and older alternator used 2 different brushes. The inner had a channel shaped mount and used 3 screws. The outer had a "Z" shaped mount and only had one screw. It is the same as both your brushes on the '80 and newer alternator.

So, you're looking for the 81611-11 brush.

So, you're looking for the 81611-11 brush.

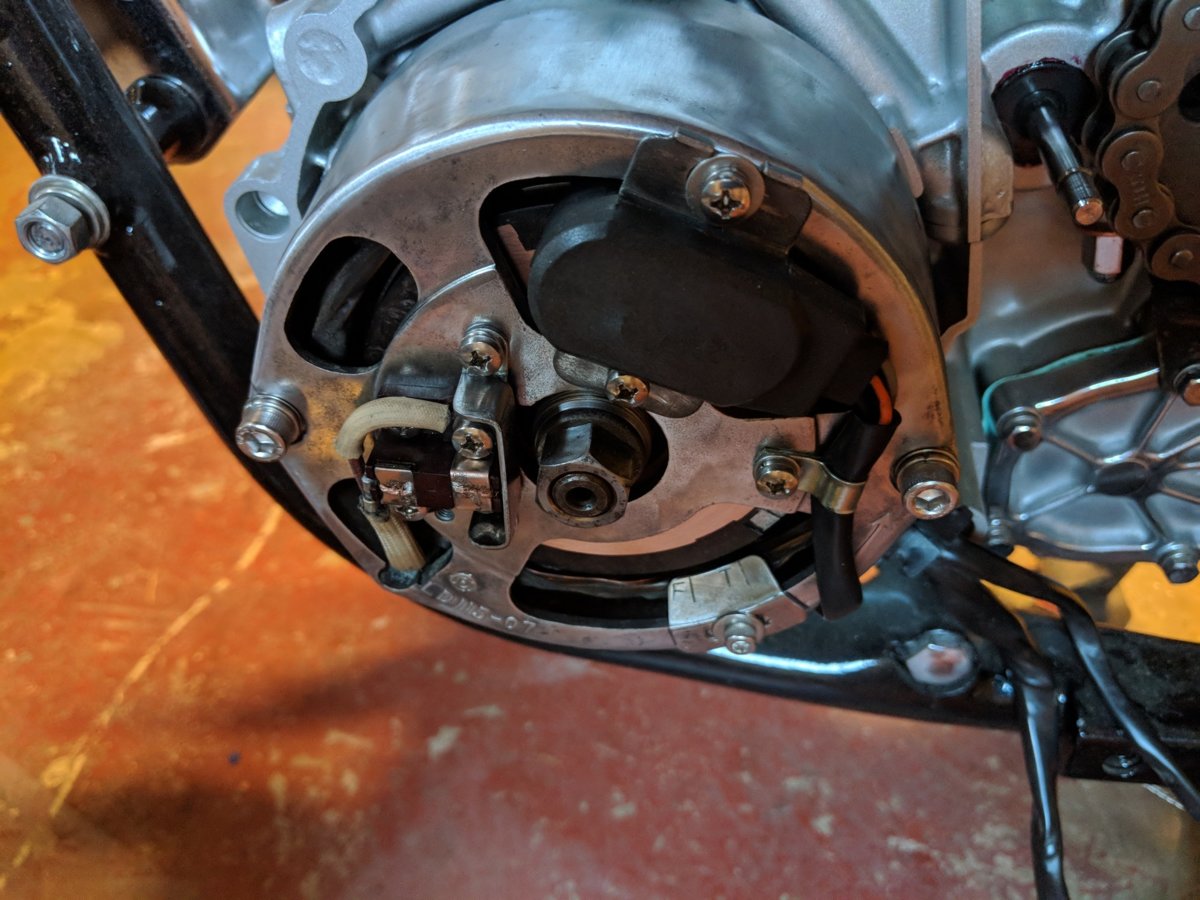

Timing Mark Check.

Today I hacked up a spark plug and made a piston bump stop....

To get my degree wheel on the crank I had to remove everything I'd carefully installed yesterday....

Hacked a few more holes in the degree wheel for access and installed it on the crank. Rotated both directions to find TDC.

.... and set the pointer to TDC. Now I get to take it all back apart and start over with torquing the rotor.

Today I hacked up a spark plug and made a piston bump stop....

To get my degree wheel on the crank I had to remove everything I'd carefully installed yesterday....

Hacked a few more holes in the degree wheel for access and installed it on the crank. Rotated both directions to find TDC.

.... and set the pointer to TDC. Now I get to take it all back apart and start over with torquing the rotor.

So.... while I was puttin' the stator back together, I noticed how the wire on the brush wraps 'around' the mount bracket. Took my Dremel and whacked about a 1/16" off the bracket (green arrow). The brush now protrudes a tad over 3/16".... a 16th more than the 1/8" the book calls the minimum. I'll still keep looking on Ebay for some NOS brushes, but I can run with what I have for now....

It's all back together and torqued....

It's all back together and torqued....

Similar threads

- Replies

- 30

- Views

- 2K