And here I thought that was the quietest running XS650 I never heared!I think there is a problem with the video link.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jim's 1980 SG Miss September

- Thread starter Jim

- Start date

well that's weird... Youtube gave me the damn link, but now the video's gone. Stand by.

Friggin Youtube.... saved it as "Private." Try it now.

MUCH better!

Very nice Jim - sounds good.

It was interesting watching that front engine mount bolt rotate as the engine vibrated.

It was interesting watching that front engine mount bolt rotate as the engine vibrated.

Friggin Youtube.... saved it as "Private." Try it now.

Well that sounds MUCH better! Poor thing just needed some gas! It sounds really nice and strong, congratulations.

I see fall riding in your future!

Saweeeet! Jim

Ya know Jim, a thought just occurred to me. You're good man. You can make em run without gas!

You can make em run without gas!

Yeah.... still scratchin' my head on that one....

Best I can figure is I musta' turned the gas on several hours before I started it. Don't remember doin' that... but it's the only explanation I can come up with.

That's why you're called Jimgyver!

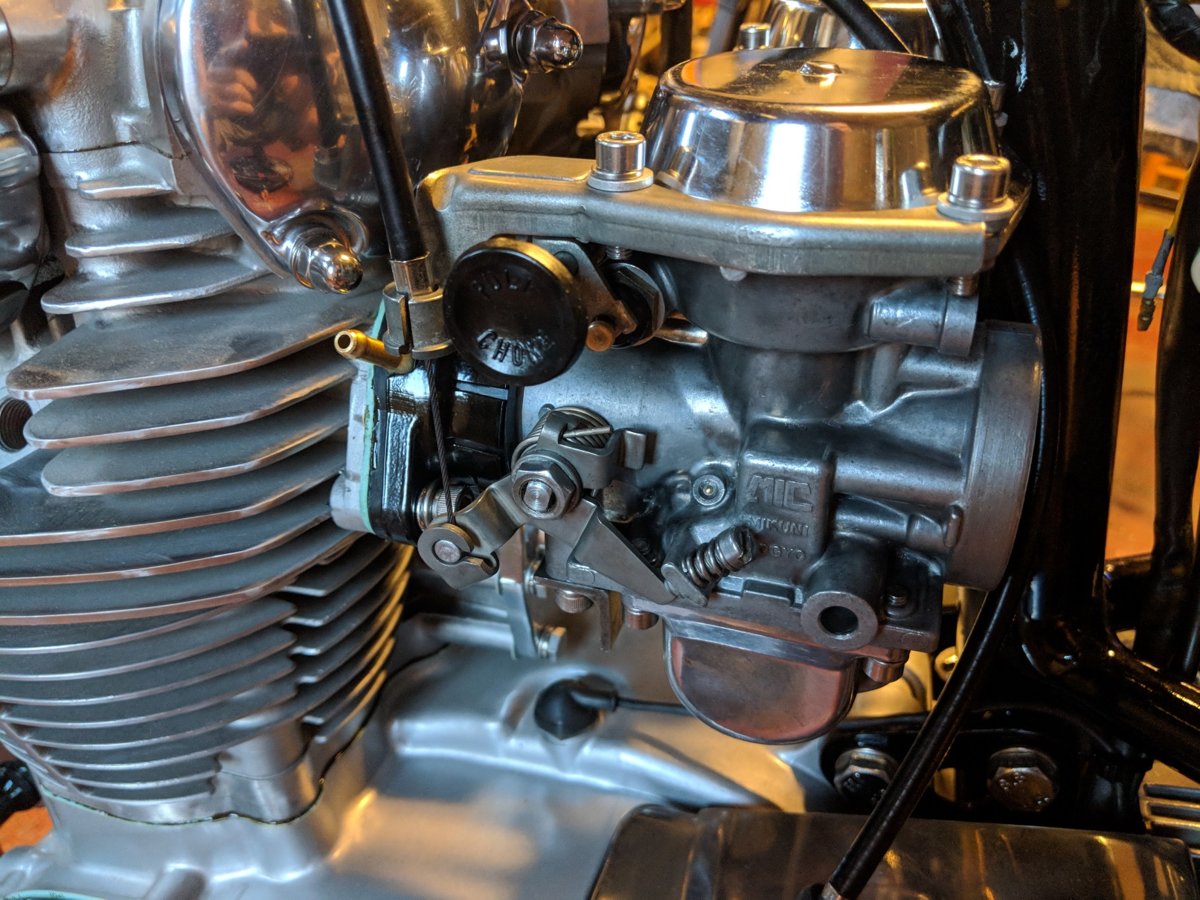

Carbs.

I'm backtracking a little.... documenting the carbs. Move along.....nothing to see here.....

Both carb bodies and parts soaked in carb cleaner for two days, flushed with hot water, dried with shop air. All passageways sprayed with WD40 and blown out again.

Polished float bowls (like you guys didn't jus' know I'd do that.. ).

).

Slide drop test was 28 sec. on left and 32 on right.

New OEM butterfly shaft seals in both.

New OEM brass floats in both.

New OEM float valve and seat in both.

New mix screw o-rings in both (thanks @gggGary ).

Replaced missing main jet washer on left carb (thanks @weekendrider ).

New ARS intake rubbers both sides.

New brass inlet 'T' from XS650 SHOP

#135 mains (new)... Both. Bumped to 137.5 (new) on 4/13/19

#42.5 pilots (old) .....Both.Bumped to 45 (new) on 4/13/19 Returned to #42.5 in Oct 19 Went back to the 45 in the summer of 2020 because of the GN250 conversion.

#135 air (new)..........Both.

Y-O needle jet (new) Both.

5HX-12 needle (old) Both.

3-1/2 turns initial on mix screws.

New Motion Pro throttle cable (lubed).

Still need to source and install spring and ball for choke shaft detent. Done.

I'm backtracking a little.... documenting the carbs. Move along.....nothing to see here.....

Both carb bodies and parts soaked in carb cleaner for two days, flushed with hot water, dried with shop air. All passageways sprayed with WD40 and blown out again.

Polished float bowls (like you guys didn't jus' know I'd do that..

Slide drop test was 28 sec. on left and 32 on right.

New OEM butterfly shaft seals in both.

New OEM brass floats in both.

New OEM float valve and seat in both.

New mix screw o-rings in both (thanks @gggGary ).

Replaced missing main jet washer on left carb (thanks @weekendrider ).

New ARS intake rubbers both sides.

New brass inlet 'T' from XS650 SHOP

#135 mains (new)... Both. Bumped to 137.5 (new) on 4/13/19

#42.5 pilots (old) .....Both.

#135 air (new)..........Both.

Y-O needle jet (new) Both.

5HX-12 needle (old) Both.

3-1/2 turns initial on mix screws.

New Motion Pro throttle cable (lubed).

Last edited:

Spring and ball tip Jim. When buddy took his BS34's apart from his 80SG he didn't realize there was a teeny ball and spring in there. Never to be seen again.

Turns out in one of my carb parts boxes I had some teeny balls and springs I tucked away from drilling out some grease zerks to use to attach clear tubing to when I was verifying float levels. Those balls and springs were the perfect size. Huh, who knew. Little bit of fun holding that spring down while putting it all together though.

Got an extra grease zerk kickin' around?

Turns out in one of my carb parts boxes I had some teeny balls and springs I tucked away from drilling out some grease zerks to use to attach clear tubing to when I was verifying float levels. Those balls and springs were the perfect size. Huh, who knew. Little bit of fun holding that spring down while putting it all together though.

Got an extra grease zerk kickin' around?

Got a parts bin full of 'em Robin. Thanks!!!Got an extra grease zerk kickin' around?

I sometimes wonder why I'm such a pack rat, and wouldn't just throw them little things away, and then other times I'm happy I am.......lol.

JimD54, I have just been back at Entry 1029 where you made your valve adjusting tool. Great idea to have that 4mm square hole offset at 45 Degrees to the other. This means you can easily and more comfortably do the adjustment independent of where the lash screw is positioned. Of course that little bend at each end is also essential:

The one I made a while back needs to be upgraded to something more like yours. Thank you for the good ideas! I am also planning a jig/fixture to hold my frame for repainting. Will not be a master piece like yours but a wooden version employing the two opposite garage walls as supports.

The one I made a while back needs to be upgraded to something more like yours. Thank you for the good ideas! I am also planning a jig/fixture to hold my frame for repainting. Will not be a master piece like yours but a wooden version employing the two opposite garage walls as supports.

JimD54, I have just been back at Entry 1029 where you made your valve adjusting tool. Great idea to have that 4mm square hole offset at 45 Degrees to the other. This means you can easily and more comfortably do the adjustment independent of where the lash screw is positioned. Of course that little bend at each end is also essential:

.

Actually if Jim was real anal he would have turned that square file 45º after he had the square hole filed and then filed a second square to make it an 8 point socket and not have to flip tool end to end during the adjustment procedure!

I'd better run and hide now before someone in Mo. throws something at me!

That is a nifty tool but I just use the 4mm open end from a Craftsman metric ignition wrench set. I must say, that is one great little wrench set, perfect for the little jobs like carb work. Small very slim wrenches but not too big so you don't over-tighten things.

I had a pouch of Craftsman ign. wrenches at one time. Appears to have grown some legs...

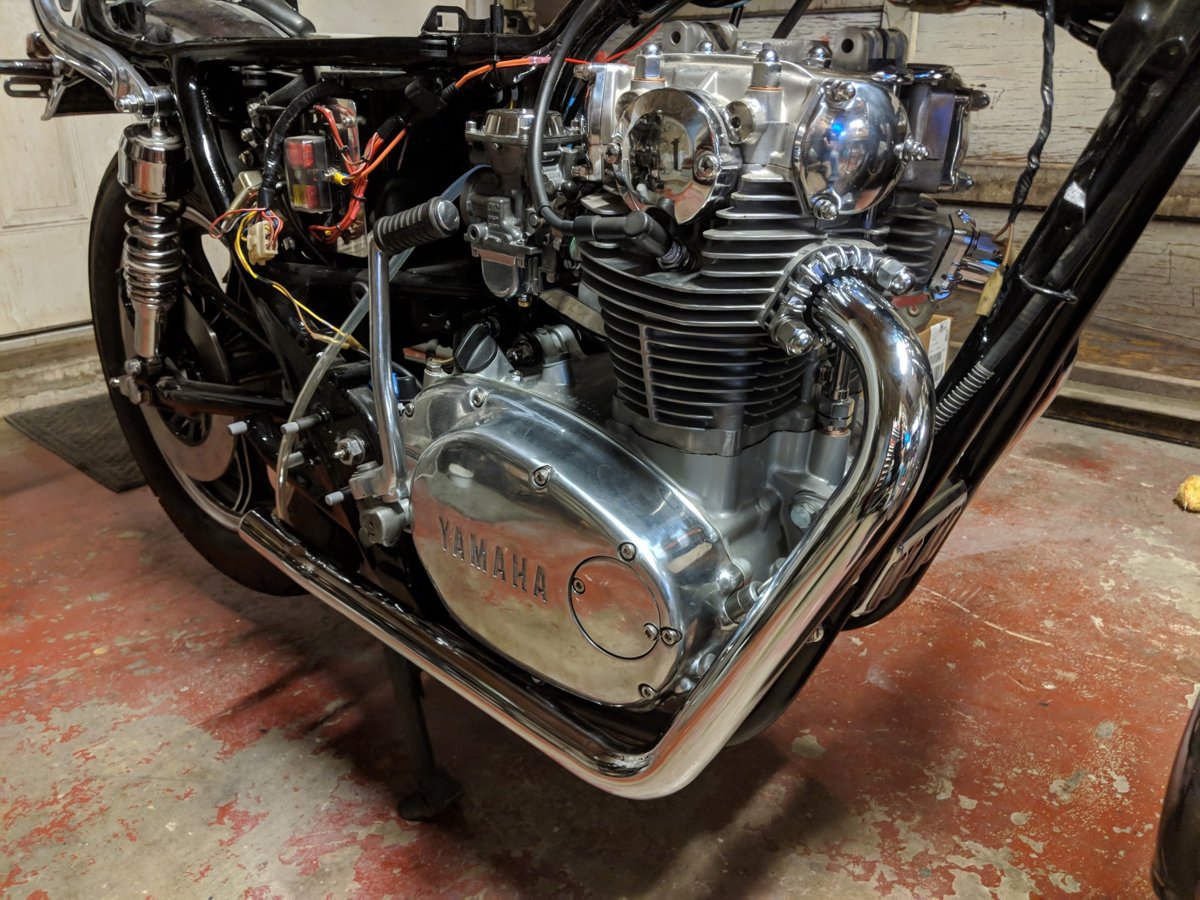

Engine Porn....

MikesXS headers showed up a little bit ago....

MikesXS headers showed up a little bit ago....

Very pretty!

Similar threads

- Replies

- 30

- Views

- 2K