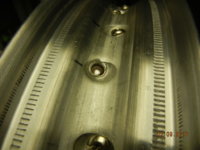

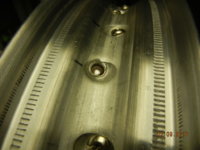

Did this today, I kinda made a spoke hole "straightener" out of an old masonry impact bit with a Makita drill, grinder and dremel cut off wheel. It let me aim the hole to the matching hole in the hub and recut the the nipple seat for a more square to the hole connection. By grinding the cutting slots away from the seat I kept a rather round hole at the inner seat end, hope that will be a stronger mod than just twisting a running drill bit. This rim is a kinda, fitz all, fitz none well, deal) I would say it could not be laced to the front hub without the spoke hole remodel. I started and soon was unable to get nipples threaded to spokes through the rim holes. I found the the same issue last year lacing the same rim to a rear hub, I ended up filing spoke holes on that rear but wasn't real happy with the result, some bowing of the spokes is visible. I am going to do a second rear set up using this rim and hole straightener or a mark II bit version.

From mikes site:

"WM 2.5x18x36 hole Rim, polished aluminum.

Very hard to find new. Classic 36 hole pattern will work with many vintage bikes. Works with XS650, XS400.

This is a quality rim comparable to what you see on other sites for much more money.

Great for chopper and bobber projects.

DOT approved.

Rim Profile WM Type

Part #34-0007 $99.95 USD Ea."

Also from Mikes a front spoke set to install an 18" rim on the XS650 disk front hub.

https://www.mikesxs.net/yamaha-xs650-stainless-steel-spoke-set-18-front-36-spoke.html

The joining seam is not perfect, I'd say acceptable but there is a bit of a bump, this has been true with all the mikes rims I have used. the 2.5 x 18 is not stamped anywhere, so take the DOT approved with a grain of salt.

It trued up fairly easy. I kinda like a video I just saw where cycle world went to Buchanons and the Buchanon guy said "don't drive your self nuts with a dial indicator, use a wire (I like using a magic marker) and get it decent then quit worrying, it will run just fine, tires aren't perfect either." I hemmed and hawed but finally angle ground, filed, wheeled and buffed away the 2 casting webs on the hub. Note the outer spoke heads are a bit of a sloppy fit in the hub also. The 64 spoke 21" rim conversion was very straight forward by comparison. No "Custom" work needed. Pretty sure I am going to bite the bullet, and order a pair of Michelin pilot power 3 110/80 18 front tires and run them with tubes on both ends. The rear will be my 5th wheel lace job this spring.

So I guess for wider rims the choice is work with these $100 dollar rims or spend 3 times that at Buchanons.

pics in no particular order.

rim lace true wm3 wm4 stainless steel spokes rim hub wheel front rear drum disk truing true lace pattern cross swing arm swingarm.

I'm real happy with the swingarm based truing stand I built.

edit 1-23 to add the link to the 18" front spoke set from MikesXS

From mikes site:

"WM 2.5x18x36 hole Rim, polished aluminum.

Very hard to find new. Classic 36 hole pattern will work with many vintage bikes. Works with XS650, XS400.

This is a quality rim comparable to what you see on other sites for much more money.

Great for chopper and bobber projects.

DOT approved.

Rim Profile WM Type

Part #34-0007 $99.95 USD Ea."

Also from Mikes a front spoke set to install an 18" rim on the XS650 disk front hub.

https://www.mikesxs.net/yamaha-xs650-stainless-steel-spoke-set-18-front-36-spoke.html

The joining seam is not perfect, I'd say acceptable but there is a bit of a bump, this has been true with all the mikes rims I have used. the 2.5 x 18 is not stamped anywhere, so take the DOT approved with a grain of salt.

It trued up fairly easy. I kinda like a video I just saw where cycle world went to Buchanons and the Buchanon guy said "don't drive your self nuts with a dial indicator, use a wire (I like using a magic marker) and get it decent then quit worrying, it will run just fine, tires aren't perfect either." I hemmed and hawed but finally angle ground, filed, wheeled and buffed away the 2 casting webs on the hub. Note the outer spoke heads are a bit of a sloppy fit in the hub also. The 64 spoke 21" rim conversion was very straight forward by comparison. No "Custom" work needed. Pretty sure I am going to bite the bullet, and order a pair of Michelin pilot power 3 110/80 18 front tires and run them with tubes on both ends. The rear will be my 5th wheel lace job this spring.

So I guess for wider rims the choice is work with these $100 dollar rims or spend 3 times that at Buchanons.

pics in no particular order.

rim lace true wm3 wm4 stainless steel spokes rim hub wheel front rear drum disk truing true lace pattern cross swing arm swingarm.

I'm real happy with the swingarm based truing stand I built.

edit 1-23 to add the link to the 18" front spoke set from MikesXS

Last edited: