I haven't bought a bike work stand/lift because it would be in the way much of the time.

I do have 2 bike jacks which are functional, but they don't allow full access the the underside, of course.

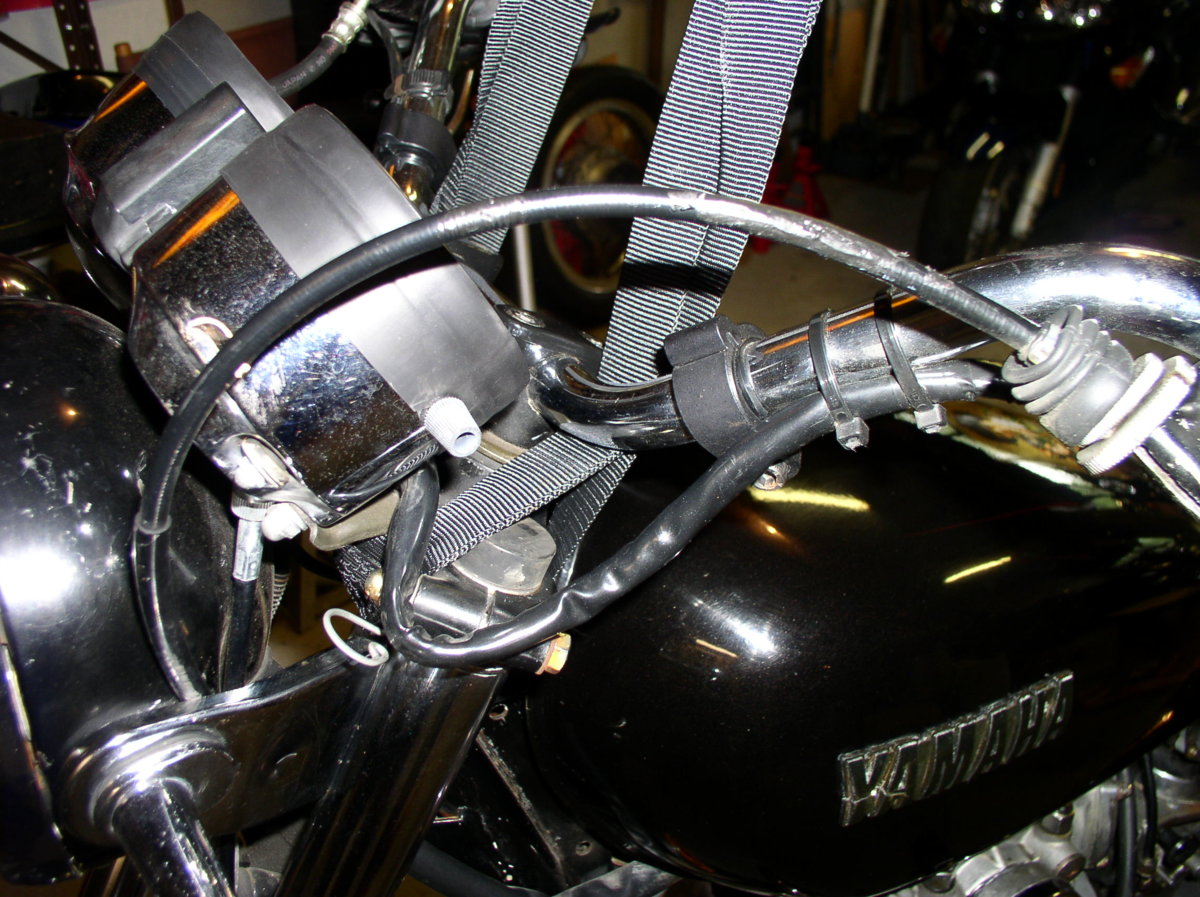

Given that I put in an electric hoist awhile ago, today I used soft ties to work out a lift strategy.

I suppose I have already answered my own question, as I successfully lifted (nicely) the '80 off the ground just now, but I am concerned about the integrity of the triple tree clamp.

Opinions ? Have you also done this ?

I do have 2 bike jacks which are functional, but they don't allow full access the the underside, of course.

Given that I put in an electric hoist awhile ago, today I used soft ties to work out a lift strategy.

I suppose I have already answered my own question, as I successfully lifted (nicely) the '80 off the ground just now, but I am concerned about the integrity of the triple tree clamp.

Opinions ? Have you also done this ?