THE CURIOUS CASE OF THE EARLY CLUTCH

Today I pulled my clutch apart for inspection. I have already purchased a complete newer / improved clutch assembly from forum member Daniel Black, which I intend to install. However, this older style clutch interests me and I had considered running it for a while, but I think it would be problematic due to some obsolete rubber o rings used in the assembly. There are other unique properties that I thought some of you gear heads might find interesting. So here we go!

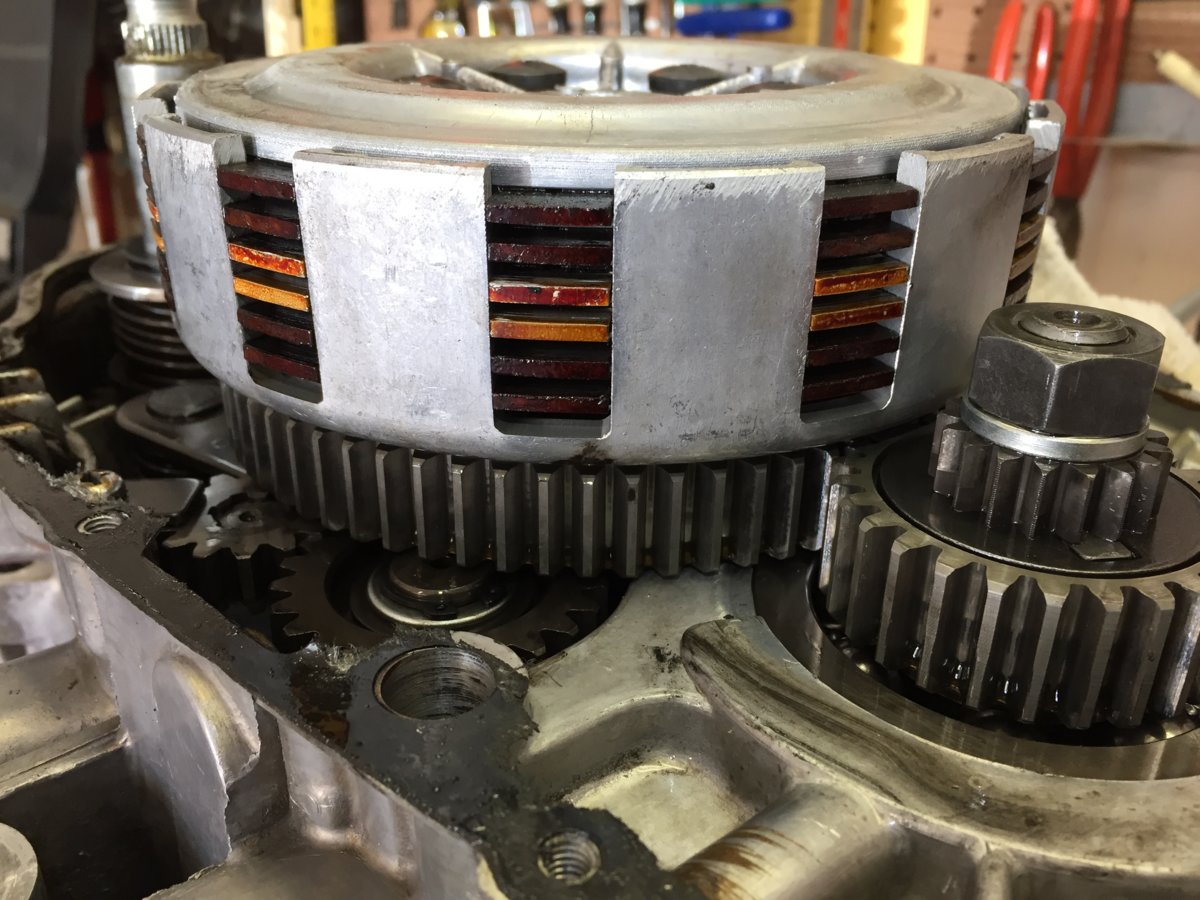

Here is what I’m starting with, six friction plates instead of the more modern seven, and take note of the color of the two friction plates in the center. 5Twins picked up on that right away, he said that the two center plates have aluminum centers and he was quite correct.

What really surprised me though was that the other four friction plates seem to be made up entirely of fiber. ( If I’m wrong please correct me ) but I could not see any metal in them and a magnet won’t stick to them.

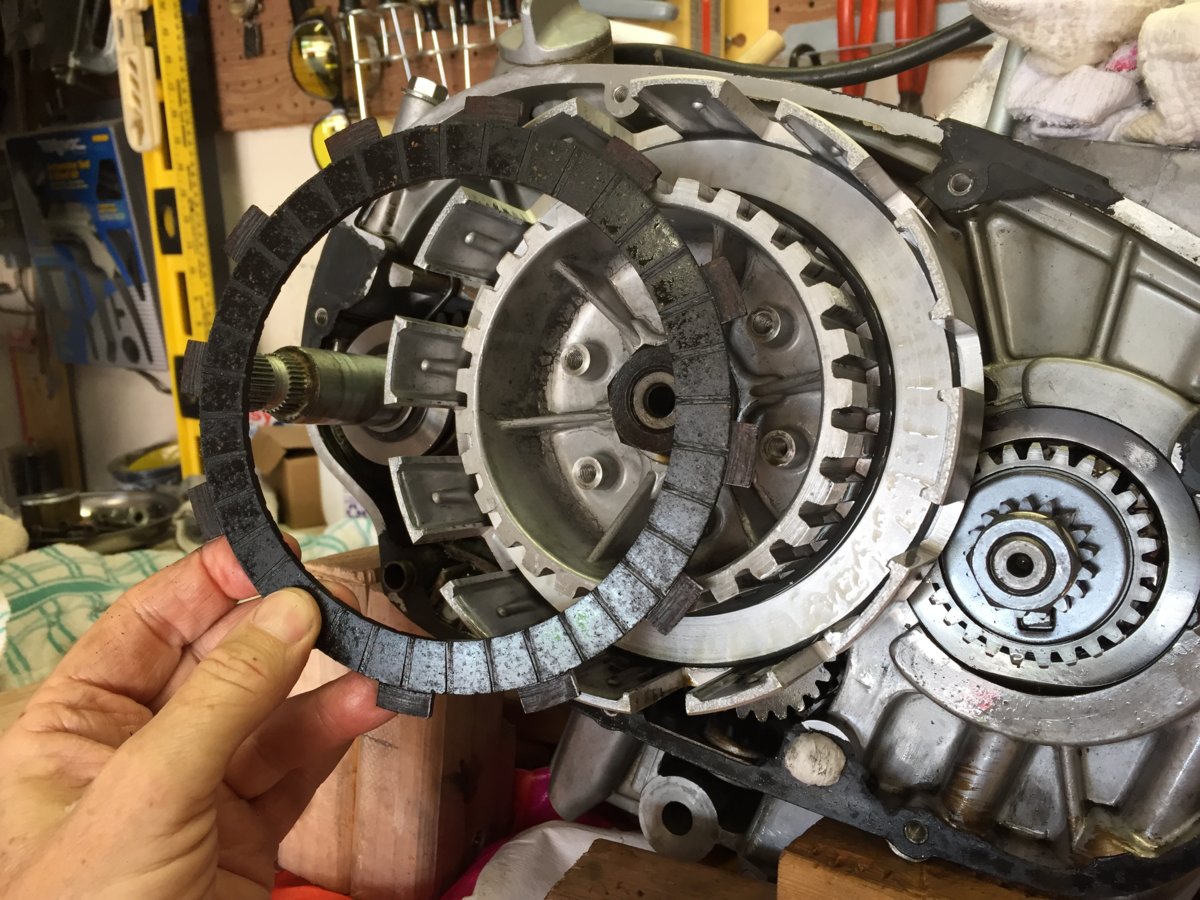

Another difference is the absence of alignment marks on the pressure plate.

Speaking of pressure plates, one of the reasons that I purchased a newer clutch assembly is that on this one, the only solid connection between the hub and the pressure plate is the six bolts. On the newer pressure plates they have splines on the outer edge that tie into the hub to make it much stronger. ( that info from 5Twins )

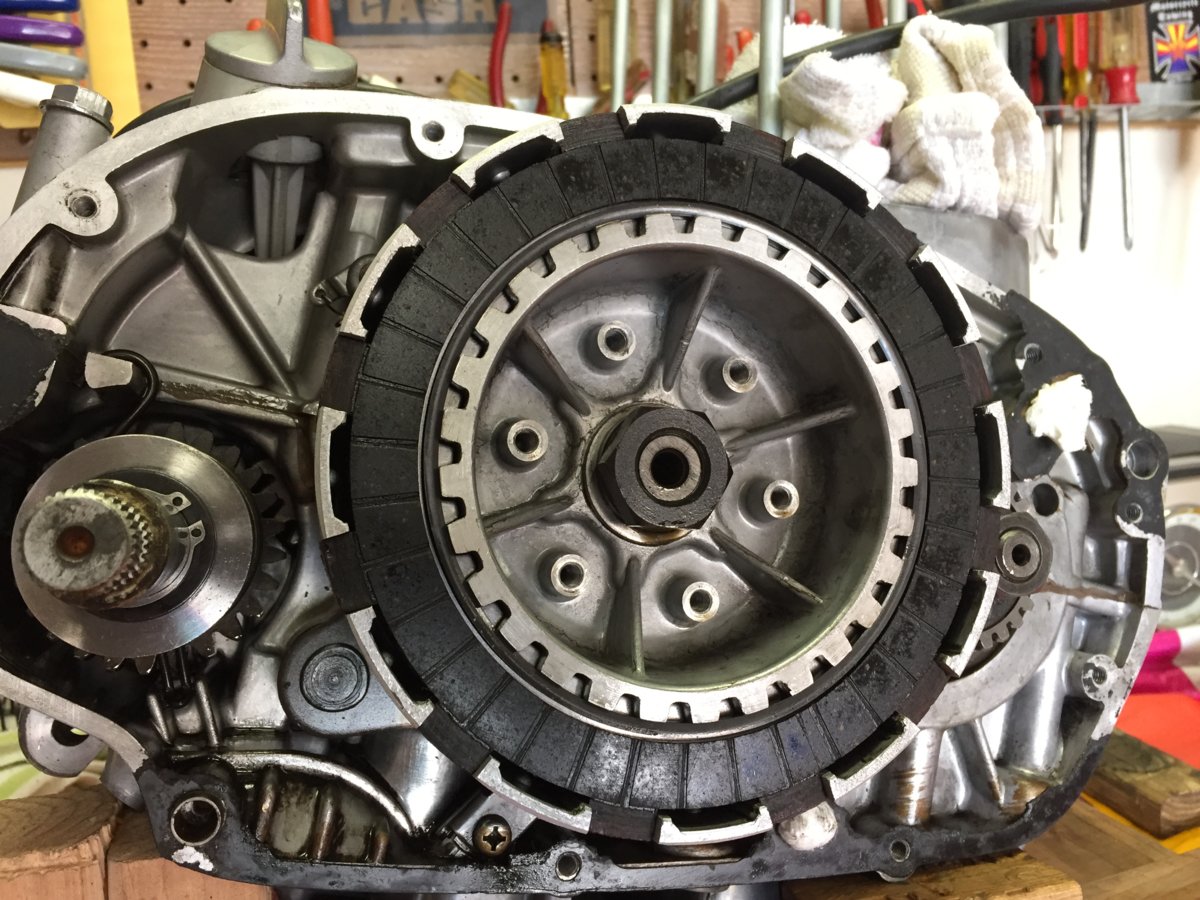

And then there are the o rings. One of the primary reasons I switched to a newer unit. Here you can see how they are positioned on the hub.

They are not really an o ring at all, they are shaped like a channel, and these are still very pliable and look to be in original shape.

I also pulled my starter gear for inspection. The gear looked to be really not all that bad, some wear on the teeth, all the rubber is in perfect condition. I checked the slip resistance of the wishbone spring with a fishing scale and it slipped at ONLY TWO POUNDS !!

I intend to replace the gear assembly and squeeze the new spring down to increase the slip resistance.

So until we meet again,and the case is sol-ved!

Later, Bob

Today I pulled my clutch apart for inspection. I have already purchased a complete newer / improved clutch assembly from forum member Daniel Black, which I intend to install. However, this older style clutch interests me and I had considered running it for a while, but I think it would be problematic due to some obsolete rubber o rings used in the assembly. There are other unique properties that I thought some of you gear heads might find interesting. So here we go!

Here is what I’m starting with, six friction plates instead of the more modern seven, and take note of the color of the two friction plates in the center. 5Twins picked up on that right away, he said that the two center plates have aluminum centers and he was quite correct.

What really surprised me though was that the other four friction plates seem to be made up entirely of fiber. ( If I’m wrong please correct me ) but I could not see any metal in them and a magnet won’t stick to them.

Another difference is the absence of alignment marks on the pressure plate.

Speaking of pressure plates, one of the reasons that I purchased a newer clutch assembly is that on this one, the only solid connection between the hub and the pressure plate is the six bolts. On the newer pressure plates they have splines on the outer edge that tie into the hub to make it much stronger. ( that info from 5Twins )

And then there are the o rings. One of the primary reasons I switched to a newer unit. Here you can see how they are positioned on the hub.

They are not really an o ring at all, they are shaped like a channel, and these are still very pliable and look to be in original shape.

I also pulled my starter gear for inspection. The gear looked to be really not all that bad, some wear on the teeth, all the rubber is in perfect condition. I checked the slip resistance of the wishbone spring with a fishing scale and it slipped at ONLY TWO POUNDS !!

I intend to replace the gear assembly and squeeze the new spring down to increase the slip resistance.

So until we meet again,and the case is sol-ved!

Later, Bob

I’ve got you on speed dial buddy!

I’ve got you on speed dial buddy!