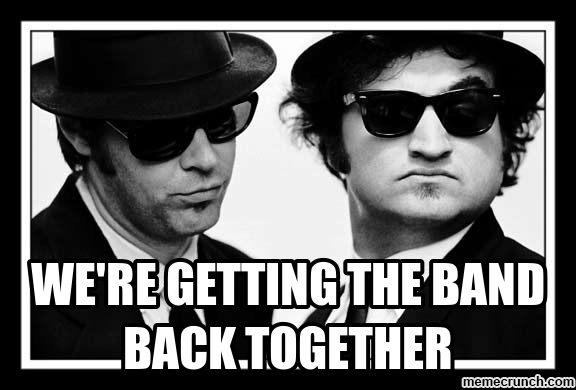

EXCITING NEWS!

That’s right, Jake and Elwood, the bike brothers are getting back together this weekend.

With a little luck, by Sunday afternoon my engine will be back in its frame where it belongs! I’ll get to try out my new chain hoist too! Stay tuned..........I’m so excited I gotta bust a move!

That’s right, Jake and Elwood, the bike brothers are getting back together this weekend.

With a little luck, by Sunday afternoon my engine will be back in its frame where it belongs! I’ll get to try out my new chain hoist too! Stay tuned..........I’m so excited I gotta bust a move!