Meddy

XS650 Addict

Hello forum members.

Well, after lurking on this site for some time now I thought I should share my build with the xs650 community.

Bit of a story behind my 79 special but bear with me I have lots of pics.

I bought this bike back in 1997 off a friend of a friend, and it was sort of my comeback bike after going through the usual things like bringing up kids, mortgage etc.

Anyway, I rode it for 12 or 18 months until one day there was bang, lots of smoke and only running on one cylinder.

So full of enthusiasm, to get it going again I pulled the motor out took the head off, and found this;

Well, at the time it was still attached to the conrod but you know what I mean

This was pre internet days, well it was for me living in a tiny town of 1200 people at the bottom of Victoria, Australia, and our local dealer wasn't very helpful with spare parts etc, so I decided to strip the bike totally label and bag everything and pack it all away in the shed as a future project.

So about 18 years later, and after getting sick of moving bits and pieces of bike around various sheds over the years I decide its time to start the rebuild.

So this is what I had to start with;

And after almost 20 years of my pretty ordinary storage, this was what I had to deal with.

So, earlier this year the frame, swingarm, battery box and lower for legs went off to be sandblasted and painted in 2 pack gloss black.

In the mean time I made a start on cleaning up the engine, at first I was hoping to get away with just giving the outside a clean up but it soon became apparent that my very ordinary storage meant I would have to completely strip the bottom end to clean out all the years of built up crap, now it was really getting serious.

Next, the clean up.

Cheers,

Mick.

Well, after lurking on this site for some time now I thought I should share my build with the xs650 community.

Bit of a story behind my 79 special but bear with me I have lots of pics.

I bought this bike back in 1997 off a friend of a friend, and it was sort of my comeback bike after going through the usual things like bringing up kids, mortgage etc.

Anyway, I rode it for 12 or 18 months until one day there was bang, lots of smoke and only running on one cylinder.

So full of enthusiasm, to get it going again I pulled the motor out took the head off, and found this;

Well, at the time it was still attached to the conrod but you know what I mean

This was pre internet days, well it was for me living in a tiny town of 1200 people at the bottom of Victoria, Australia, and our local dealer wasn't very helpful with spare parts etc, so I decided to strip the bike totally label and bag everything and pack it all away in the shed as a future project.

So about 18 years later, and after getting sick of moving bits and pieces of bike around various sheds over the years I decide its time to start the rebuild.

So this is what I had to start with;

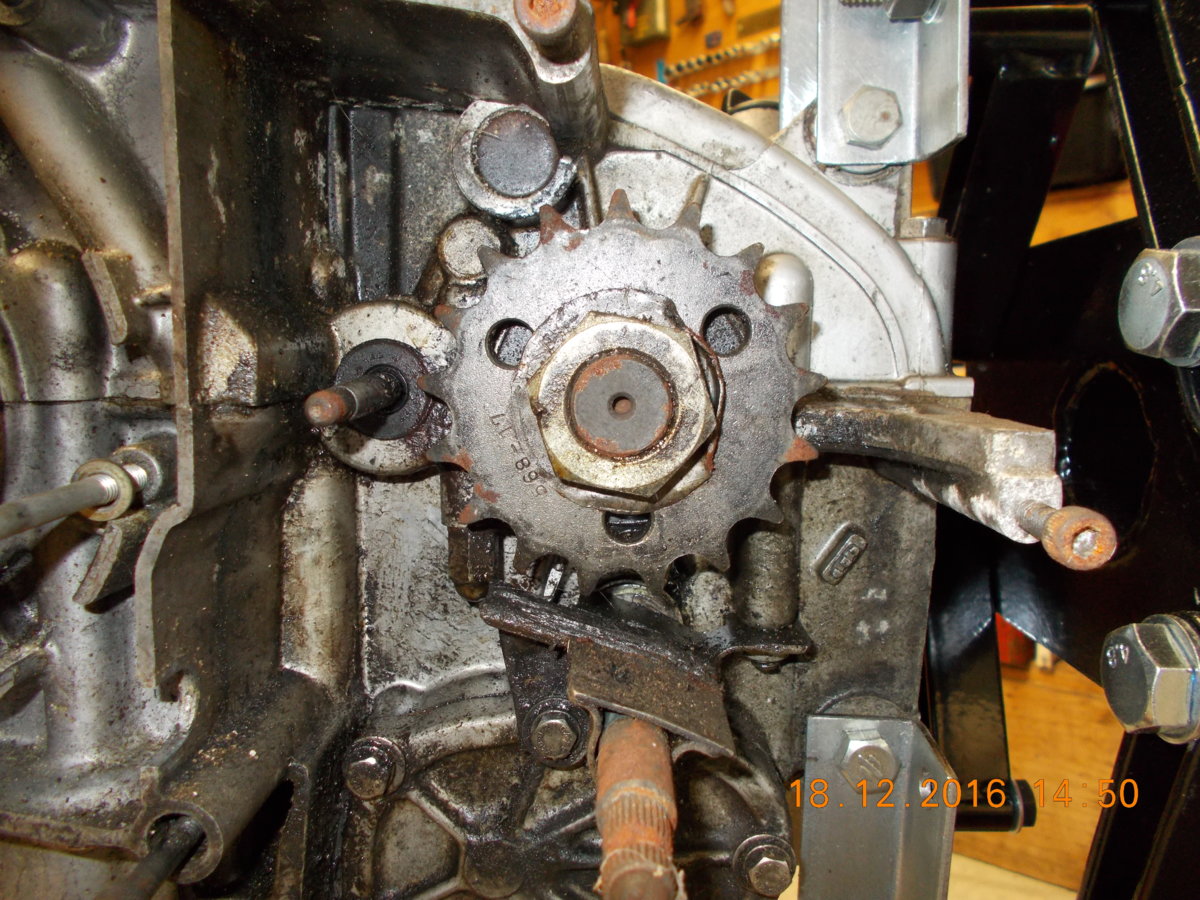

And after almost 20 years of my pretty ordinary storage, this was what I had to deal with.

So, earlier this year the frame, swingarm, battery box and lower for legs went off to be sandblasted and painted in 2 pack gloss black.

In the mean time I made a start on cleaning up the engine, at first I was hoping to get away with just giving the outside a clean up but it soon became apparent that my very ordinary storage meant I would have to completely strip the bottom end to clean out all the years of built up crap, now it was really getting serious.

Next, the clean up.

Cheers,

Mick.