Have you replaced the throttle shaft seals? You might try opening the mix screws another 1/4 or 1/2 turn.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 60th birthday present

- Thread starter Mailman

- Start date

-

- Tags

- 1977 xs 650d chain and sprockets clutch pushrod seal cranckcase seal new front master cylinder pamco e-advance pamco ultimate high output ignition rebuild brake caliper rebuild brakes rebuilt carburetors replace clutch solid state rectifier stainless steel braid front brake line starter gear fix steering head bearings vr-115 regulator

Thanks Daniel, yeah I need to just settle down and get methodical again. I am just having trouble trying to figure out where to go from here. So you think jetting could be an issue with the rpm's hanging up?

My money is on the routing of the throttle cable Bob (and Daniel with your clutch too - as discussed last week). Those details must be sorted out anyway and they are both MUCH easier to do than a whole bunch of jetting and so-on.

As I may have pointed out before: when I first got Lucille running, I had difficulty shifting gears AND I found that if I turned the handlebars from lock to lock, the engine sped up A LOT - and all of that made for a couple of highly "stimulating" moments at corners

. I fiddled and diddled with the clutch adjustments and advance mechanism etc. - and finally, I had a loyal assistant come and turn the bars back and forth (engine off) while I simply sat on my shop stool and watched the throttle lever on the LH carb. The ding-danged thing moved about 3/16" when the bars went to the lock position.

. I fiddled and diddled with the clutch adjustments and advance mechanism etc. - and finally, I had a loyal assistant come and turn the bars back and forth (engine off) while I simply sat on my shop stool and watched the throttle lever on the LH carb. The ding-danged thing moved about 3/16" when the bars went to the lock position.

Soooo.... after consuming a calming and tastey shop BEvERage, I took off the tank and stared really hard at the cable routing diagrams in the manual and sure enough - I had the throttle AND the clutch cables quite wrong (and Daniel and I discussed the fact that his clutch cable was incorrectly routed last Thursday as well). The space is tight along the tunnel under that tank and you've got to get things corrected routed or they simply do not work properly. Anyhow, once I sorted those little gremlins out - the clutch issues and the throttle racing issues simply....disappeared.

As for the head gasket - Bob, cut yourself some slack. I would take a bit of a break and simply buy some oil while enjoying the bike. Do that darned head gasket later during the crummy winter weather.

Ooops - you don't HAVE crummy winter weather in Arizona.....hmmmmm....

...well, then do it inside the air conditioned house during the unspeakably hot summer weather.

...well, then do it inside the air conditioned house during the unspeakably hot summer weather.Keep us posted Bob - we know that you're discouraged and we understand why - but remember that you've got people all over the darned planet pulling for you buddy!

Pete

Bringing an old bike back from years of no or poor maintenance can be frustrating. It takes time. It took me about 4 years to find and resolve all of the problem areas on my bike.

High idle hovering........................these are the things below, that I chased and eventually solved:

There must be no air leakage..........carbs, manifolds, throttle shaft seals.

Butterflys in the carbs must be able to close 100%. If one of the butterflys is not centred, it can rub on the carb body and not close fully. You can use a slip of paper as a feeler gauge to be sure that both butterflys are exactly synced together. Once you use the slip of paper as a bench sync, you follow that up using the U tube manometer.

Very important to get the mixture screw adjusted correctly on each carb. I did that using the dead cylinder method.

On the 70 to 79 carbs, BS38s, the needle jet, rubber O-ring can wear out and fall apart. When that happens, it allows unmetered fuel/air mixture to sneak around the needle jet, and the idle will hang and wander.

My ATU did not stick or bind, but it was just plain worn out with too much slop between moving parts. Also, spring tension was never correct. Pamco was the solution for that.

High idle hovering........................these are the things below, that I chased and eventually solved:

There must be no air leakage..........carbs, manifolds, throttle shaft seals.

Butterflys in the carbs must be able to close 100%. If one of the butterflys is not centred, it can rub on the carb body and not close fully. You can use a slip of paper as a feeler gauge to be sure that both butterflys are exactly synced together. Once you use the slip of paper as a bench sync, you follow that up using the U tube manometer.

Very important to get the mixture screw adjusted correctly on each carb. I did that using the dead cylinder method.

On the 70 to 79 carbs, BS38s, the needle jet, rubber O-ring can wear out and fall apart. When that happens, it allows unmetered fuel/air mixture to sneak around the needle jet, and the idle will hang and wander.

My ATU did not stick or bind, but it was just plain worn out with too much slop between moving parts. Also, spring tension was never correct. Pamco was the solution for that.

One more thing - on your turn signal issues: check inside the headlight bucket. It took me about 8 tries to get everything working due to loose connections in there. It is very tight and that makes it easy to have something go silly when you button it up. Why the heck didn't MamaYama make that danged bucket an inch or so deeper - stupid!!

The other issue I had (no flippin' wonder I call her Lucille after Lucille Ball of I Love Lucy...) was that my P/O had tried to adapt the rear signals to use dual filament bulbs and in the process he had butchered the sockets very badly. Also, inside the stems of three of my turn signal stalks - the insulation on the wire carrying power to the bulb had worn through due to a sharp edge on the stalk stud - and that was causing a short.

After MUCH sturm und drang I simply gave up and bought four new signal stalks from Mikes (no hate please) - and they look perfect, fit perfect and work great.

Sooooo.....check that your turn signal stalk wires are not cut and shorting out.....

The other issue I had (no flippin' wonder I call her Lucille after Lucille Ball of I Love Lucy...) was that my P/O had tried to adapt the rear signals to use dual filament bulbs and in the process he had butchered the sockets very badly. Also, inside the stems of three of my turn signal stalks - the insulation on the wire carrying power to the bulb had worn through due to a sharp edge on the stalk stud - and that was causing a short.

After MUCH sturm und drang I simply gave up and bought four new signal stalks from Mikes (no hate please) - and they look perfect, fit perfect and work great.

Sooooo.....check that your turn signal stalk wires are not cut and shorting out.....

Weekendrider, yes I replaced the throttle shaft seals when I rebuilt the carburetors.

Retiredgentleman, I replaced the needle jet o rings when I rebuilt the carbs. I have not done any adjusting of the carburetors yet. Also one of my carburetors had some wear on the inside of the body from the butterfly rubbing against it. I sincerely hope it has not ruined the carburetor. AND I really think I am going to add the Pamco E Advancer just to eliminate that as a problem.

Pete, even though I have lubricated the old throttle cable, I might just get a new one , they're not expensive, and I will once again check for proper routing. I have had all that stuff loose recently, it's possible that it is not routed properly. And about the flashers, I wasn't clear, the flashers work, the flasher indicators on the dash don't work.

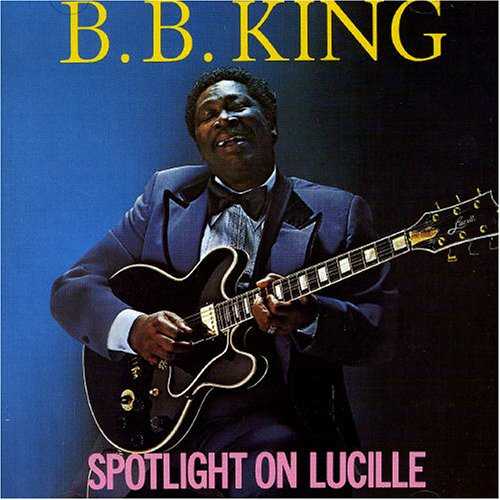

And BTW, here I always thought Lucille was named after B.B. Kings guitar Lucille! Must be because I am a blues lover! I used to have B B King as a ring tone on my phone. Haha

Retiredgentleman, I replaced the needle jet o rings when I rebuilt the carbs. I have not done any adjusting of the carburetors yet. Also one of my carburetors had some wear on the inside of the body from the butterfly rubbing against it. I sincerely hope it has not ruined the carburetor. AND I really think I am going to add the Pamco E Advancer just to eliminate that as a problem.

Pete, even though I have lubricated the old throttle cable, I might just get a new one , they're not expensive, and I will once again check for proper routing. I have had all that stuff loose recently, it's possible that it is not routed properly. And about the flashers, I wasn't clear, the flashers work, the flasher indicators on the dash don't work.

And BTW, here I always thought Lucille was named after B.B. Kings guitar Lucille! Must be because I am a blues lover! I used to have B B King as a ring tone on my phone. Haha

DanielBlack

XS650 Junkie

Oh, those indicators are almost definitely bad bulbs if the turn signals themselves work. I had a few go in quick succession and I replaced them with LED equivalents. 1000 miles later they are still good. I also like how they catch my eye better in the daylight.

TimeMachine

SeventyEighte

Mailman ! Today I have a rt engine side cover leak,, rt frt head gasket leak, too.. I think your rpm variation is linkage shaft alignment /sync or more jetting. Use 5twns chart for sure. I'll try a "re-torque" next time I ride it and that may help a head gasket leak. But fortunately electrically running on shhh. better not talk about it. BTW those pipes in video sound Greeat ! -RT

BB & his Lucille are indeed terrific but my Lucille suffered so many calamities when she first arrived that she reminded me of Lucy and her mishaps with her sidekick Ethel Mertz.

On the turn signals....I still recommend that you check the connections inside the bucket. The power for the indicators passes through there too. I went through it and cleaned and tightened every one of those danged bullet connectors several times.

On the turn signals....I still recommend that you check the connections inside the bucket. The power for the indicators passes through there too. I went through it and cleaned and tightened every one of those danged bullet connectors several times.

Bob Kelly III

Ranch Kid from way back,.... that got Old !

MaxPete is right ! I've also had my share of turn-signal woes..... all due to the push and twist bulbs 1157's (or is it 1156 ?) ... 9 times out of 10 if you wiggle the bulb with the turn signal on it will start working.... I like to clean them up good with emery cloth on the inside and the bulb base, and then sprey everything real good with WD-40

..... and as Max says the wire going through there goes through a small grommet that never stays put... and without it your sure to get a short

nothing inside a turnsignal is smothe it's all cast and sharp I have been known to pull the wire out and wrap the entire length with Black tape just to end the flustration..... that works !

.....

Bob.......

..... and as Max says the wire going through there goes through a small grommet that never stays put... and without it your sure to get a short

nothing inside a turnsignal is smothe it's all cast and sharp I have been known to pull the wire out and wrap the entire length with Black tape just to end the flustration..... that works !

.....

Bob.......

I'm back! Ok ok , I was feeling low yesterday after my little test ride, but I've got a new plan of attack to address my problems. At first I thought the Pamco ignition solved all my problems. Not so. But on the positive side it did do a lot of good. It starts faster than ever before and it settles down to a very steady and stable idle. I also really think I've got a handle on my persistent air leaks after numerous attempts to get them under control.

So yesterday the biggest problem I was having was the hanging rpm's. I intend to approach this two ways.

1. The first one is easy, new throttle cable and ensure the routing is proper. The old cable looks to be original to the bike.

2. I have been studying up in the amckayltd carb manual and my bike is exhibiting signs of a lean condition. I have never adjusted my carbs and I think it needs the mixture screws richened up some, maybe even up one size on the pilot jet. That had been suggested earlier and I think that's probably right. ( I am running K+N filters in the stock airbox.)

The other problem I was having yesterday was the ignition not advancing fully. Even though the mechanical advance mech had been dis assembled , everything ( rod included ) cleaned and lubed. I am going to get the Pamco E Advance and be done with it.

The other things ,

speedo not working (Meh! I'll figure that out )

Instrument lights , ditto

Head gasket leak , I'll get around to it.

Right now I'm going to find happiness in the things I've done right so far and remain hopeful that I'll figure out the rest.

Anybody see where I set my beer?

So yesterday the biggest problem I was having was the hanging rpm's. I intend to approach this two ways.

1. The first one is easy, new throttle cable and ensure the routing is proper. The old cable looks to be original to the bike.

2. I have been studying up in the amckayltd carb manual and my bike is exhibiting signs of a lean condition. I have never adjusted my carbs and I think it needs the mixture screws richened up some, maybe even up one size on the pilot jet. That had been suggested earlier and I think that's probably right. ( I am running K+N filters in the stock airbox.)

The other problem I was having yesterday was the ignition not advancing fully. Even though the mechanical advance mech had been dis assembled , everything ( rod included ) cleaned and lubed. I am going to get the Pamco E Advance and be done with it.

The other things ,

speedo not working (Meh! I'll figure that out )

Instrument lights , ditto

Head gasket leak , I'll get around to it.

Right now I'm going to find happiness in the things I've done right so far and remain hopeful that I'll figure out the rest.

Anybody see where I set my beer?

What you have to understand about your particular carb set is it came with the smallest mains ever put in any 650 model. They are fine on a totally stock machine but start modding things and that small main is quickly outpaced. You only have the one mod (K&N airbox filters) but it could be enough. It could be the pilot but it might be the main instead. The main influences the whole range. The pilot draws it's fuel supply from just above the main. What the main lets through it what the pilot has to draw from. The easiest and quickest change or "test" you could do would be to pop 125 mains in there. That might just fix things. The mains can be swapped through the drain plug without removing the carbs.

After cleaning and lubing all the parts, I don't understand why your advance isn't working properly. It rotates the advance rod a small amount, maybe 1/8 of a turn, between the retarded and full advance positions. You can check it by hand with the motor off. Just grab the little 10mm nut that holds the little disc on the advance side and rotate it. The rod should turn until the weights are pushed out to the stops. When you let go, it should snap back to the retarded position. Check to see that it turns easily and snaps back. All I can figure is maybe it's binding up somehow or maybe the springs were changed sometime in the past to some that are wrong and too strong.

After cleaning and lubing all the parts, I don't understand why your advance isn't working properly. It rotates the advance rod a small amount, maybe 1/8 of a turn, between the retarded and full advance positions. You can check it by hand with the motor off. Just grab the little 10mm nut that holds the little disc on the advance side and rotate it. The rod should turn until the weights are pushed out to the stops. When you let go, it should snap back to the retarded position. Check to see that it turns easily and snaps back. All I can figure is maybe it's binding up somehow or maybe the springs were changed sometime in the past to some that are wrong and too strong.

Thanks for that 5Twins, then I shall plan on bumping up the mains and see what happens.

With regards to the advance, it's even a little stranger than that. It was advancing properly when I had the points in. After installing the Pamco, it advances almost fully, probably a little more than 3/4's of the way. But just won't go that last little bit. Weird I know.

With regards to the advance, it's even a little stranger than that. It was advancing properly when I had the points in. After installing the Pamco, it advances almost fully, probably a little more than 3/4's of the way. But just won't go that last little bit. Weird I know.

Homer Simpson.....................a great guy and kinda my hero! We share a common bond, since we both worked in Nuclear Power Plants.

Actually, now that I think about it, we look alike as well

Back on topic...........................if you have solved the air leaks, then its time to focus on the carbs. If you have stock CV carbs, they are great carbs, that work really well. But, and its a big but..........................they are a precision device, and everything inside them has to be working correctly. Make sure the float levels are set correctly. Butterflys must be able to close 100% and synced to each other.

With your stock air boxes and stock exhaust, you should be using the stock size main and pilot jets, that 5twins has listed on his table about carbs. Have you remove them and confirmed they are the correct size? Yamaha engineers (likely with Mikuni's help) tested and installed the correct size jets, and they will work for you. Make sure the pilot jets are not partially plugged, as can easily happen, due to the orifice being so small.

If the above is correct, then you want to use the dead cylinder method, to adjust the mixture screws. I find it works best for me to get the rpm down low, to maybe 500 to 800 rpm while running on the one cylinder. Use a fan blowing air across the engine.

On my 1978 SE engine, using stock air box and stock exhausts.......................guess what..............the stock main and pilot jets work just fine. I had the mixture screws adjusted to 3 turns out, with the stock #27.5 pilot jet, and engine ran quite well. However when the mixture screws are out at 3 turns, they are so far open that they lose the throttling ability of the needle, and its more difficult to sense the sweet spot,when the perfect mixture is found. I replaced the #27.5 pilot jet with a #30 pilot jet, to see how that would work. I found my new sweet spot was at 1.75 turns out, and because the mixture needle was at a better position to throttle the mixture flow, the 1.75 turns was much easier to tune.The 1.75 turns was right on the money, and I've been using that setting for the last 5 years, and no longer ever touch them. That's how Mikuni CV carbs are........................once you get them set right, you just leave them alone.

With the 1977, you have a different version of the CV carb than I do, but the same principles apply. Just thought you might be glad to get benefit of my experience.

Actually, now that I think about it, we look alike as well

Back on topic...........................if you have solved the air leaks, then its time to focus on the carbs. If you have stock CV carbs, they are great carbs, that work really well. But, and its a big but..........................they are a precision device, and everything inside them has to be working correctly. Make sure the float levels are set correctly. Butterflys must be able to close 100% and synced to each other.

With your stock air boxes and stock exhaust, you should be using the stock size main and pilot jets, that 5twins has listed on his table about carbs. Have you remove them and confirmed they are the correct size? Yamaha engineers (likely with Mikuni's help) tested and installed the correct size jets, and they will work for you. Make sure the pilot jets are not partially plugged, as can easily happen, due to the orifice being so small.

If the above is correct, then you want to use the dead cylinder method, to adjust the mixture screws. I find it works best for me to get the rpm down low, to maybe 500 to 800 rpm while running on the one cylinder. Use a fan blowing air across the engine.

On my 1978 SE engine, using stock air box and stock exhausts.......................guess what..............the stock main and pilot jets work just fine. I had the mixture screws adjusted to 3 turns out, with the stock #27.5 pilot jet, and engine ran quite well. However when the mixture screws are out at 3 turns, they are so far open that they lose the throttling ability of the needle, and its more difficult to sense the sweet spot,when the perfect mixture is found. I replaced the #27.5 pilot jet with a #30 pilot jet, to see how that would work. I found my new sweet spot was at 1.75 turns out, and because the mixture needle was at a better position to throttle the mixture flow, the 1.75 turns was much easier to tune.The 1.75 turns was right on the money, and I've been using that setting for the last 5 years, and no longer ever touch them. That's how Mikuni CV carbs are........................once you get them set right, you just leave them alone.

With the 1977, you have a different version of the CV carb than I do, but the same principles apply. Just thought you might be glad to get benefit of my experience.

Thanks RG, I do appreciate you sharing your experiences with me. The more and more I think about things, I am becoming convinced that most of my issues now amount to proper fueling and fine tuning.

When I think back to the first time I got my bike fired up, it was absolutely wild. The engine was so terribly rough the RPM's would absolutely race if I just touched the throttle. It wouldn't idle below 1500 rpm, gas leaked from everywhere, oil was pouring out of my clutch pushrod seal and my crankcase seal. It wasn't charging. The bike on the whole was nice to look at but was a neglected mess mechanically.

Last weekend , just to be able to get it to fire right up and settle down to a steady idle and to be able to go out and ride it for 30 minutes was real progress.

I need to keep my perspective.

When I think back to the first time I got my bike fired up, it was absolutely wild. The engine was so terribly rough the RPM's would absolutely race if I just touched the throttle. It wouldn't idle below 1500 rpm, gas leaked from everywhere, oil was pouring out of my clutch pushrod seal and my crankcase seal. It wasn't charging. The bike on the whole was nice to look at but was a neglected mess mechanically.

Last weekend , just to be able to get it to fire right up and settle down to a steady idle and to be able to go out and ride it for 30 minutes was real progress.

I need to keep my perspective.

jussumguy

XS650 Addict

Hi Mailman, when your idle is hanging up, have you ever tried pushing the carburetors shut with your left hand? That would differentiate whether it is linkage or mixture. Also there's lots of 650's out there that drool oil all over themselves. It's what they do at their age.

By the way, your bike looks great!

By the way, your bike looks great!

Thanks Guy,

Yes I have messed with the linkage. It's not so much an idle problem now. The rpm's want to hang up mostly while I'm riding it. It's strange some times all it takes to get it to come back down is to crack the throttle quickly and let it snap shut.

Yes I have messed with the linkage. It's not so much an idle problem now. The rpm's want to hang up mostly while I'm riding it. It's strange some times all it takes to get it to come back down is to crack the throttle quickly and let it snap shut.

That is odd the way your advance unit is operating. You can observe it in action by shining your timing light on it as the bike runs. This will give you "freeze frame" looks at how it's operating. Rev the bike up and try to see if the weights are flinging out all the way to their stops. The only thing that gets changed with a basic Pamco install is swapping the Pamco rotor in place of the points cam. Maybe it's rubbing or hitting on something and that is stopping the advance rod from turning all the way?

RG is right about an all stock 650 running right with stock jet sizes, but yours isn't all stock anymore. I put K&N airbox replacement elements in a couple other bikes I've had and while they ran OK with no jetting changes, they ran better after I did some minor changes. In all my cases, that change was 1 or 2 up on the mains. I didn't have to fool with pilots or needle settings.

RG is right about an all stock 650 running right with stock jet sizes, but yours isn't all stock anymore. I put K&N airbox replacement elements in a couple other bikes I've had and while they ran OK with no jetting changes, they ran better after I did some minor changes. In all my cases, that change was 1 or 2 up on the mains. I didn't have to fool with pilots or needle settings.

Last edited:

Thanks 5T, I'll have another look at it next weekend.

My air box has the stock type air filters. They sure don't appear to be very restrictive, but the K&Ns must flow more air.

The hanging idle on these engines is very sensitive to the mixture. Just a small amount too lean and the idle will hang and wander.

If you follow 5twins advice, its just a matter of time and you'll get it sorted out. I hope you have the air leakage under control.......................air leaks drove me crazy for a while.

The hanging idle on these engines is very sensitive to the mixture. Just a small amount too lean and the idle will hang and wander.

If you follow 5twins advice, its just a matter of time and you'll get it sorted out. I hope you have the air leakage under control.......................air leaks drove me crazy for a while.

Last edited:

get the carb cleaner out again and spray around the throttle shafts. BS38's run in dusty conditions can wear the bushings in the bodies, and stiff dry throttle shaft seals will make the problem worse.

Similar threads

- Replies

- 785

- Views

- 81K

- Replies

- 3

- Views

- 2K

- Replies

- 1

- Views

- 2K