Yes, the wishbone shaped clip. It's a drag clip and slows the spinning of the #4 gear down so it will engage the crank gear better. When the clip gets weak, the #4 gear spins too fast and grinds against the crank gear instead of engaging it.

As far as the play in all your other gears, I don't know. It could be normal, it's been so long since I was in mine I don't remember. I'd look at some exploded parts diagrams to see if anything's missing like spacers or washers. There's some good ones here .....

http://www.boats.net/parts/search/Yamaha/Motorcycle/parts.html

As far as the play in all your other gears, I don't know. It could be normal, it's been so long since I was in mine I don't remember. I'd look at some exploded parts diagrams to see if anything's missing like spacers or washers. There's some good ones here .....

http://www.boats.net/parts/search/Yamaha/Motorcycle/parts.html

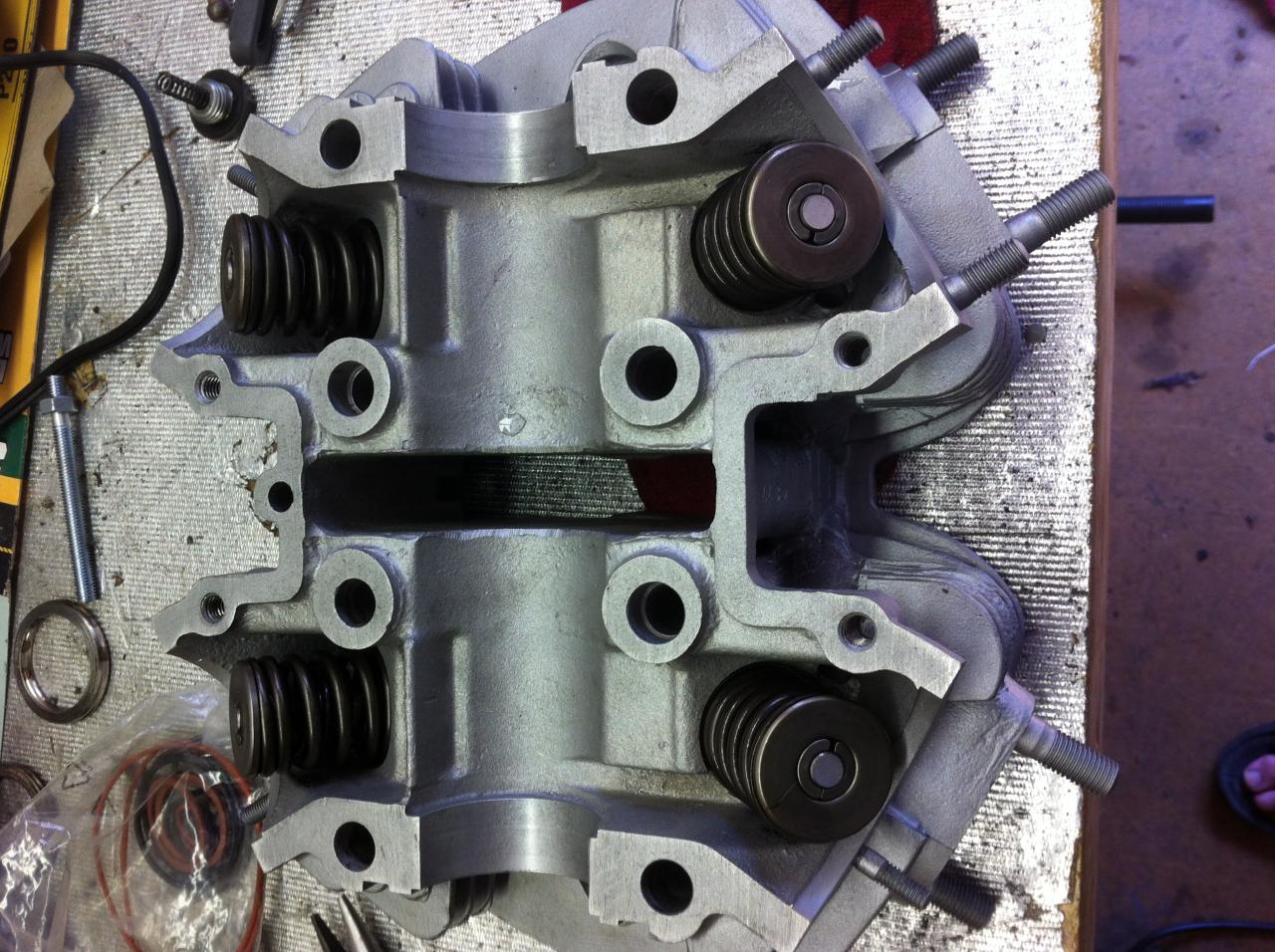

, but why did it have to be clutch boss? Of course I had it all together and was just about to start torquing the fancy new clutch screws I got from Mikes:

, but why did it have to be clutch boss? Of course I had it all together and was just about to start torquing the fancy new clutch screws I got from Mikes:

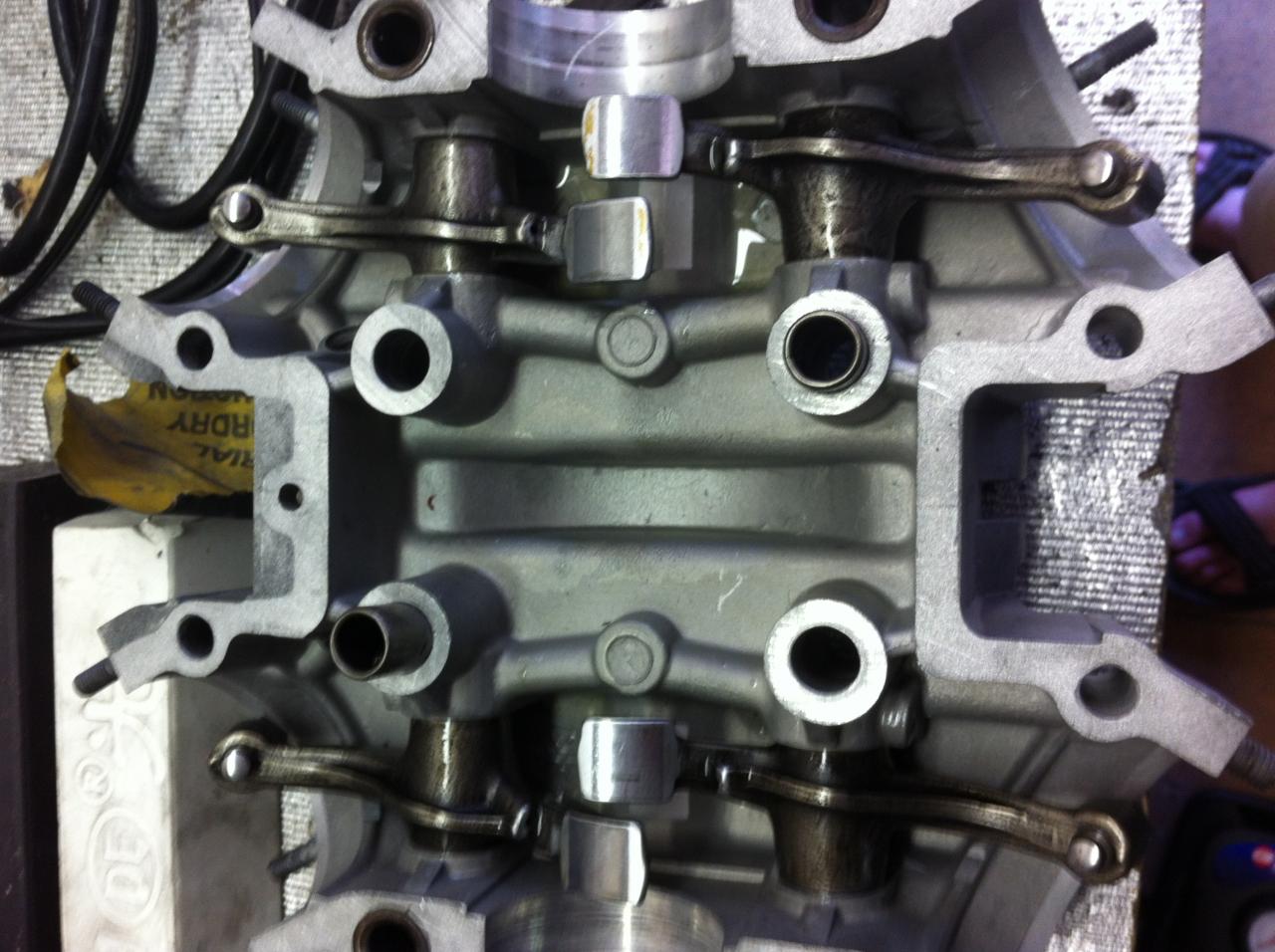

I do blame myself in terms of never done this before, but I also think this is where the maintenance guide gets really thin. It gives like 8 pages of detail on the clutch and transmission, but for this it says, "use a generous amount of oil and install the pistons." then, basically start it up. Ok, not that bad, but... no reminders about cam chain tentioners.

I do blame myself in terms of never done this before, but I also think this is where the maintenance guide gets really thin. It gives like 8 pages of detail on the clutch and transmission, but for this it says, "use a generous amount of oil and install the pistons." then, basically start it up. Ok, not that bad, but... no reminders about cam chain tentioners.