Airwolfie

XS650 Guru

So i decided to put my build thread together in one so it's easier to find.

I'm in no way an expert in building engines, in fact, this is my first ever build! So don't take this as how it should be done, but rather use this as a guide to help you build your engine. DO use manuals wherever you can,as that is what I am doing. I'm just doing this for first time builders to make a bit more sense of things, as a lot of build thread omit some stages and don't have a lot of pictures. Iwill try to document EVERYTHING I do, bu tI still may miss some stages. I have already rebuilt my rocker cover and valve cover, these are easy and straightforward, and there are tons of videos on youtube to help out on these if you struggle.

These sites were my favourite read for the build:

http://www.cmsnl.com/yamaha-xs650sh-1981_model8827/partslist/

http://thexscafedotcom.wordpress.com/2011/04/26/xs650-xs650sj-service-manual/

I also keep scanning this forum and others to get more tips and info.

Also my bits came yesterday so HOPEFULLY I will be able to finish this off this weekend. I hope this helps you guys if at all!!

Here goes!

So today I decided to start my engine rebuild!!!

I started with the shifter forks. I decided to try the upside down build like in the "german build log", sounded plausible with getting the forks and gears aligned. Turns out it's not that easy and straightforward! More on that later.

I first put the selector fork shaft in, (plug side on the outside!!) after first dipping it in a tub of oil to lubricate and fill the inside. One by one the forks were put in(hopefully the right way, let me know if they not!!). EDIT!!! Make sure the notch is over the Locating plate!! I didn't do this and resulted in having to take the right side apart again!!

Pic of the notch

View attachment 36948

And how it SHOULD look like when done...

View attachment 36923

This is thanks to YL76 who spotted this mistake, and could have spelled DISASTER!! Pics are also off him later in this thread! Thanks YL!!!!

Next came the gear selector drum.I covered it with a bit of oil, then I made sure the neutral indent is facing up(or in my case down, but to the top!), and then I carefully slid it all the way through the forks into the roller bearing at the back.

Next and finally, the cam follower pins went into their respective holes, making sure the roller side is going in first, and then the split pin goes through the hole above the pins, and bent over to hold them in.

Pics of the above so far....

The stopper assembly and locating plate need to go on next to prevent the selector drum and shaft from falling out, it also gives the "notch for selecting gears!!(you will know what I mean when you put this together!) Make sure the disc AND the locating plate go into the groove, took me about 30 minutes to figure that one out!!

I found it's quite easy to place the stopper assembly in first, with the spring attached to it, then screw the bolt in a bit to hold it in it's place, and then hook the locating plate to the spring, push it into the groove, and add the nuts to tighten it down. Bend over the locking plate( I haven't yet!) and you are done with that!

Check to see if the forks move by rotating the star shaped plate on the side.

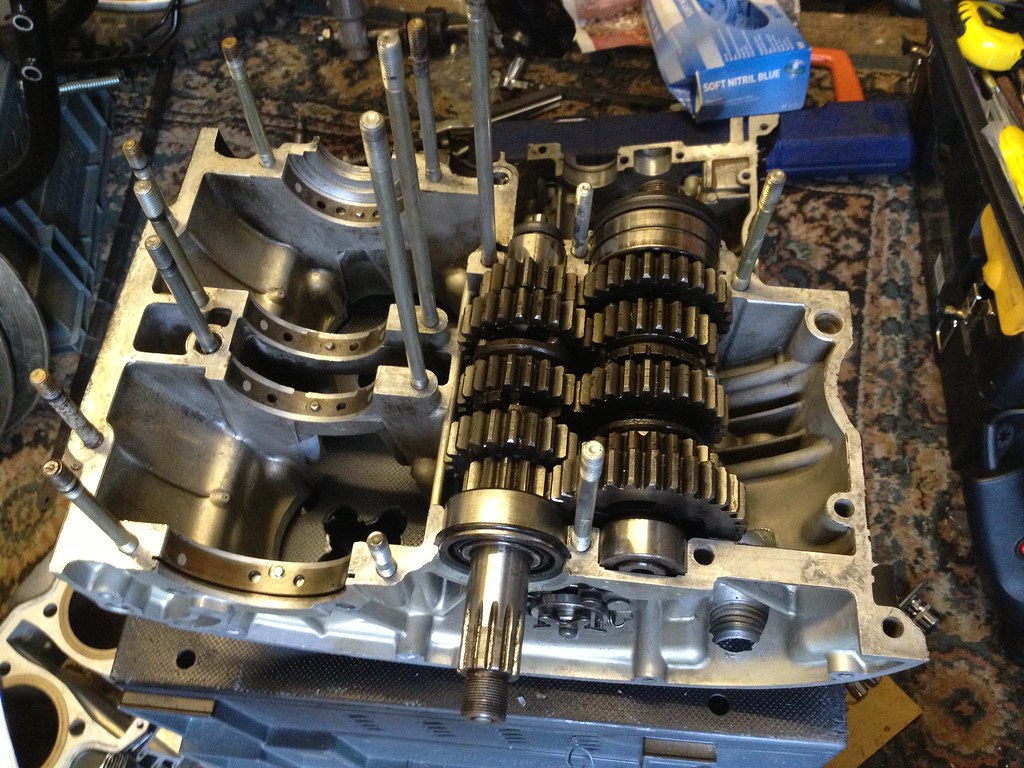

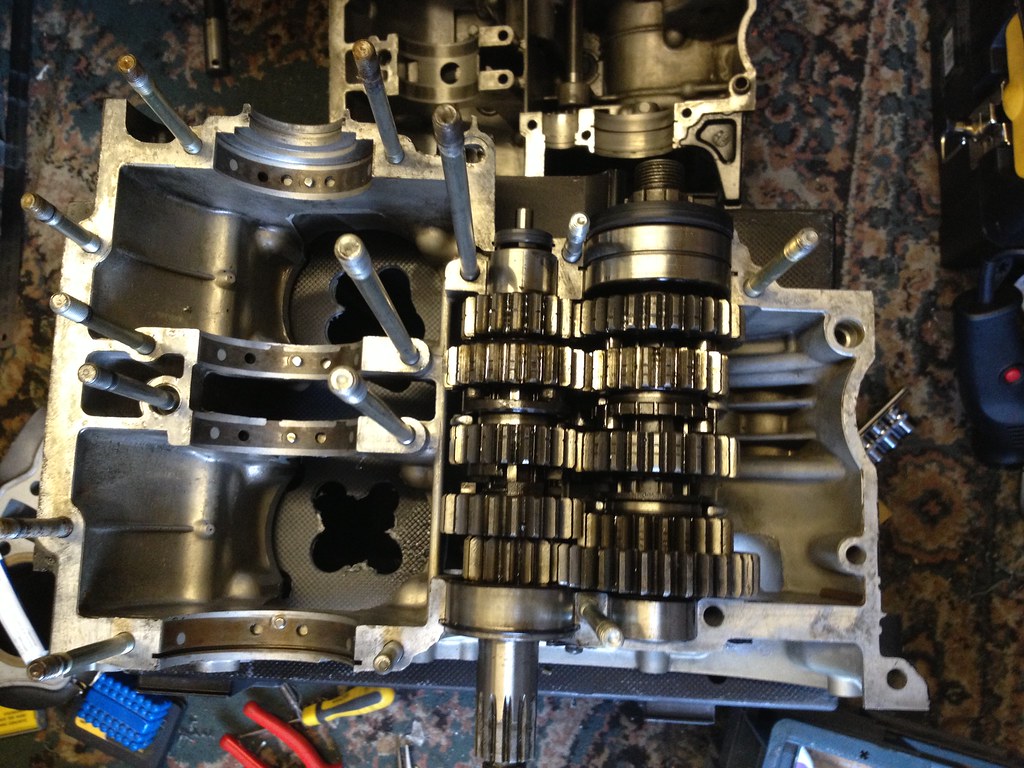

Next are the gears.

First, make sure the circlip is in position before you place the lot in!

Then the respective oil seals go on the ends.......

Then it's just a matter of aligning the forks with the gears so they fall into place.....

Before you go any further, make sure the forks move freely and the gears rotate without any thing catching.( Very satisfying thing to do!!)

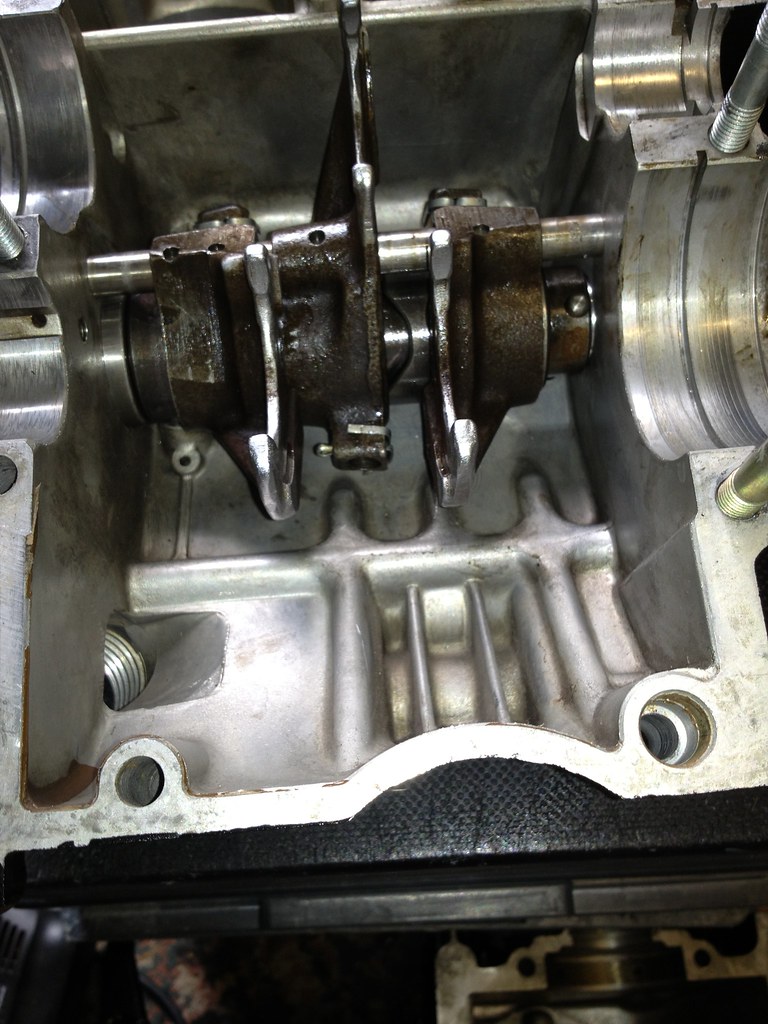

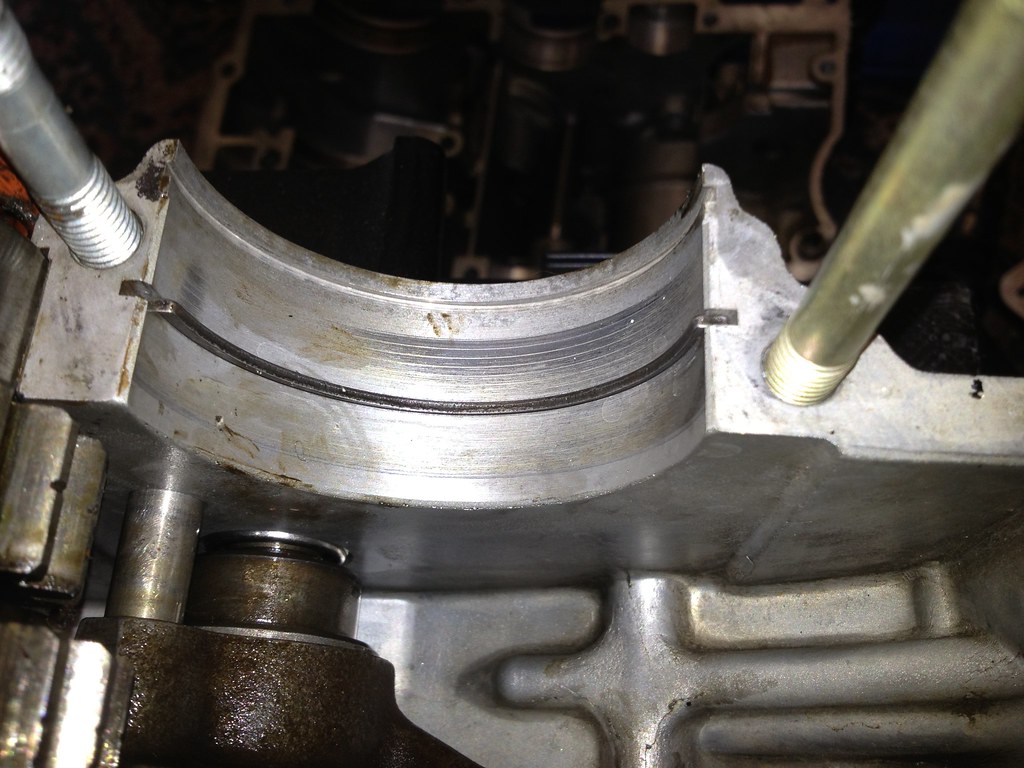

And then comes the crank shaft. Wait, not yet. I don't have the shims that go between the crank and journal ballbearing!!!!

AAAARRGGH!!!!

AAAARRGGH!!!!

So now my anxious build up to building the engine is on hold!! I don't know why I didn't check that before!!!! SO I just chucked everything in the shed and locked it, that's me f

I'm in no way an expert in building engines, in fact, this is my first ever build! So don't take this as how it should be done, but rather use this as a guide to help you build your engine. DO use manuals wherever you can,as that is what I am doing. I'm just doing this for first time builders to make a bit more sense of things, as a lot of build thread omit some stages and don't have a lot of pictures. Iwill try to document EVERYTHING I do, bu tI still may miss some stages. I have already rebuilt my rocker cover and valve cover, these are easy and straightforward, and there are tons of videos on youtube to help out on these if you struggle.

These sites were my favourite read for the build:

http://www.cmsnl.com/yamaha-xs650sh-1981_model8827/partslist/

http://thexscafedotcom.wordpress.com/2011/04/26/xs650-xs650sj-service-manual/

I also keep scanning this forum and others to get more tips and info.

Also my bits came yesterday so HOPEFULLY I will be able to finish this off this weekend. I hope this helps you guys if at all!!

Here goes!

So today I decided to start my engine rebuild!!!

I started with the shifter forks. I decided to try the upside down build like in the "german build log", sounded plausible with getting the forks and gears aligned. Turns out it's not that easy and straightforward! More on that later.

I first put the selector fork shaft in, (plug side on the outside!!) after first dipping it in a tub of oil to lubricate and fill the inside. One by one the forks were put in(hopefully the right way, let me know if they not!!). EDIT!!! Make sure the notch is over the Locating plate!! I didn't do this and resulted in having to take the right side apart again!!

Pic of the notch

View attachment 36948

And how it SHOULD look like when done...

View attachment 36923

This is thanks to YL76 who spotted this mistake, and could have spelled DISASTER!! Pics are also off him later in this thread! Thanks YL!!!!

Next came the gear selector drum.I covered it with a bit of oil, then I made sure the neutral indent is facing up(or in my case down, but to the top!), and then I carefully slid it all the way through the forks into the roller bearing at the back.

Next and finally, the cam follower pins went into their respective holes, making sure the roller side is going in first, and then the split pin goes through the hole above the pins, and bent over to hold them in.

Pics of the above so far....

The stopper assembly and locating plate need to go on next to prevent the selector drum and shaft from falling out, it also gives the "notch for selecting gears!!(you will know what I mean when you put this together!) Make sure the disc AND the locating plate go into the groove, took me about 30 minutes to figure that one out!!

I found it's quite easy to place the stopper assembly in first, with the spring attached to it, then screw the bolt in a bit to hold it in it's place, and then hook the locating plate to the spring, push it into the groove, and add the nuts to tighten it down. Bend over the locking plate( I haven't yet!) and you are done with that!

Check to see if the forks move by rotating the star shaped plate on the side.

Next are the gears.

First, make sure the circlip is in position before you place the lot in!

Then the respective oil seals go on the ends.......

Then it's just a matter of aligning the forks with the gears so they fall into place.....

Before you go any further, make sure the forks move freely and the gears rotate without any thing catching.( Very satisfying thing to do!!)

And then comes the crank shaft. Wait, not yet. I don't have the shims that go between the crank and journal ballbearing!!!!

So now my anxious build up to building the engine is on hold!! I don't know why I didn't check that before!!!! SO I just chucked everything in the shed and locked it, that's me f