Airwolfie

XS650 Guru

My first ever bike build!! WITH VIIIIIIIDDDDDDDDDEEEEEEEEEOOOOOOOOOOOO!!!!

Right, so after a few hiccups and setbacks, I have managed to start something on my bike!

I'm not trying to restore the bike, nor am I doing a proper build. At this moment in time I just want to get it going so I can sort out all the troubles and niggles before I go ahead and do a proper build! So I will be using whatever I can get cheaply! There are quite a few bits missing and rusted up, so I will be sourcing and replacing bits as I go along, as my budget is very tight!

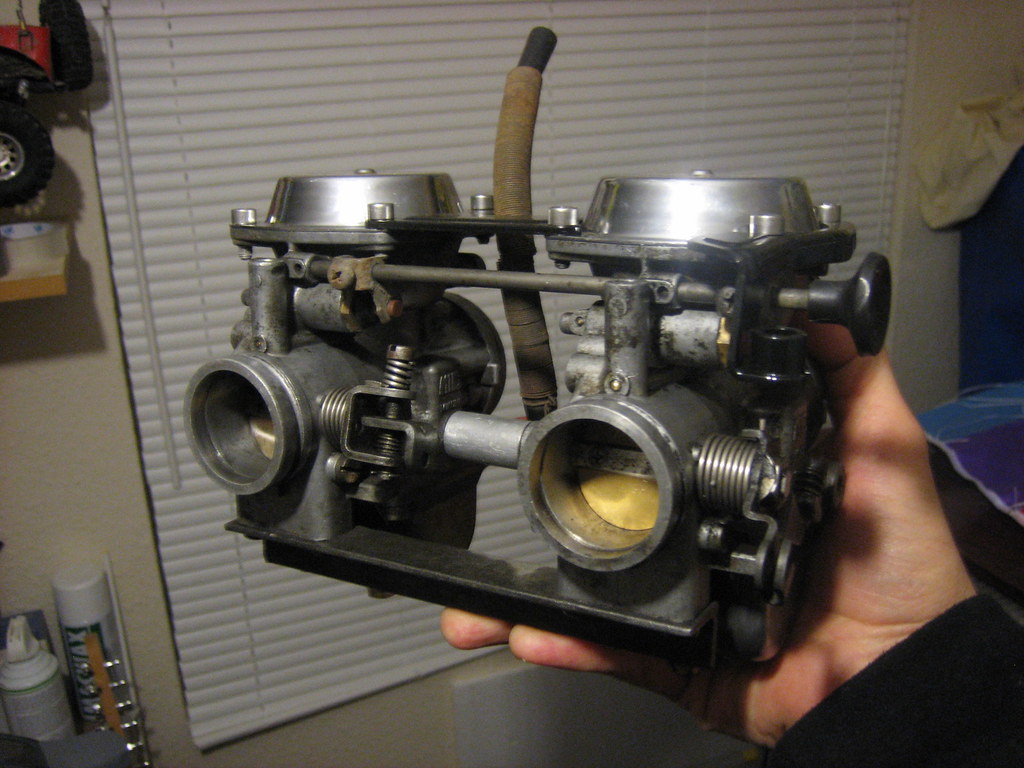

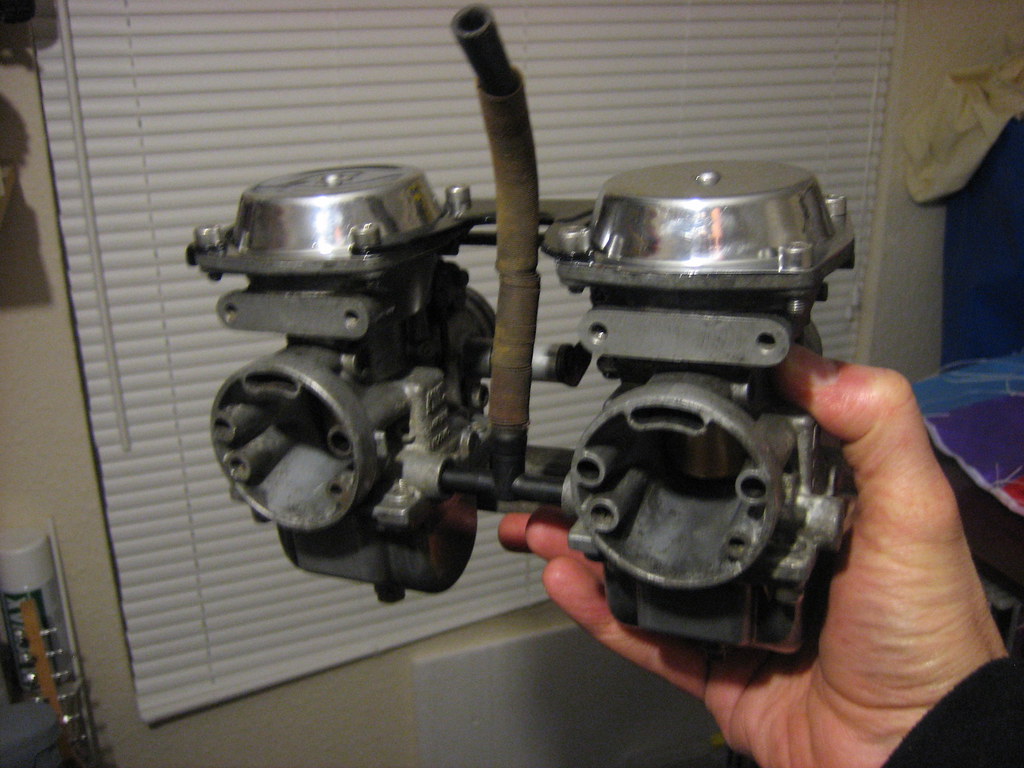

I started off with the carbs, as I thought it would be the easiest and simple to take apart and reassemble. I took lots of pictures before I started the clean up and tear down! To be honest, they are not super clean on the outside, but they are a lot cleaner than they were!

I also cleaned up the tops,and painted the brackets.

Took the insides out, and cleared all the holes and had to replace the diapragms on the one side so I decided to to do both. Got one of those without the slider on it as they are a lot cheaper. They are good quality and very robust, and they are so easy to install! Needles and floats all seem ok so I left them as is, until I get the motor put together and running.

This week I took the fro!nt forks apart and stripped and cleaned them. I was going to lower the forks,but I will do that at a later stage. No serious mods so I can see what she's like "factory fresh" The seals were so bad I had to scrape them off their perch! The rubber was very brittle and was sticking to the ally! I cleaned the oil out, gave them a good clean and smoothed them down a bit , and shot some etch primer on them as I want to paint them -yes I know!!- black. I recently discovered I have a subconscious obsession over black rattle cans, so I will use some of them, if not all of them on this build! Well maybe not the tins, we'll see!

The seals were so bad I had to scrape them off their perch! The rubber was very brittle and was sticking to the ally! I cleaned the oil out, gave them a good clean and smoothed them down a bit , and shot some etch primer on them as I want to paint them -yes I know!!- black. I recently discovered I have a subconscious obsession over black rattle cans, so I will use some of them, if not all of them on this build! Well maybe not the tins, we'll see!

On to some pics!!

The PO did this to the tank, the missus said she has to go!!

Couple of boxes!!

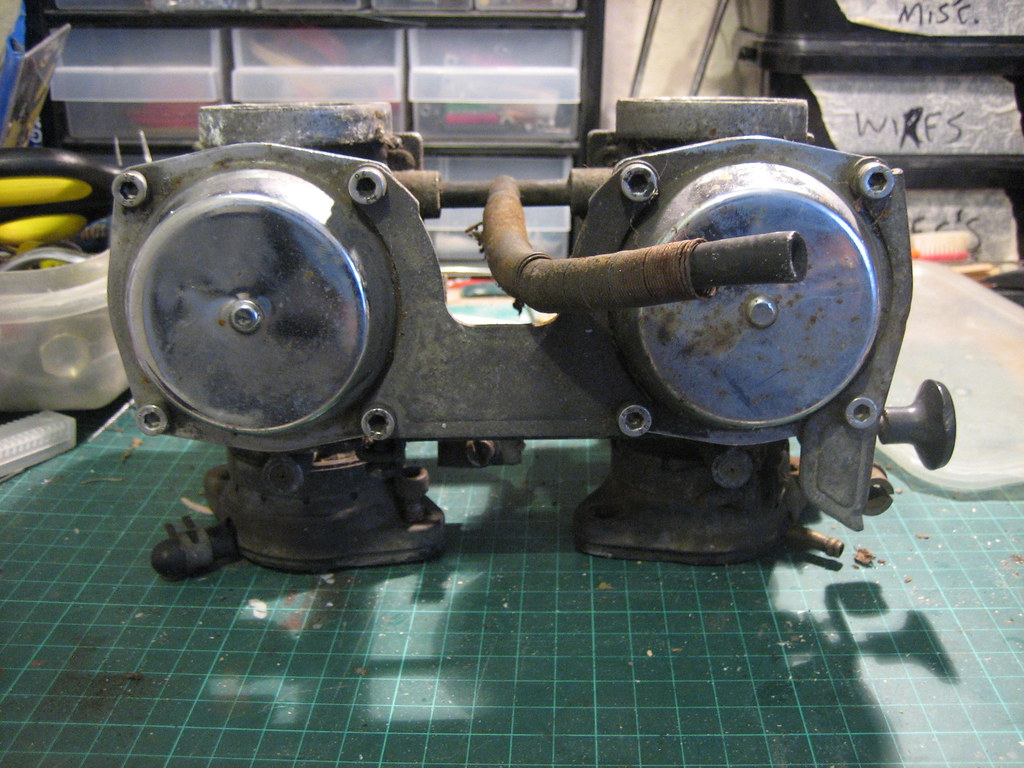

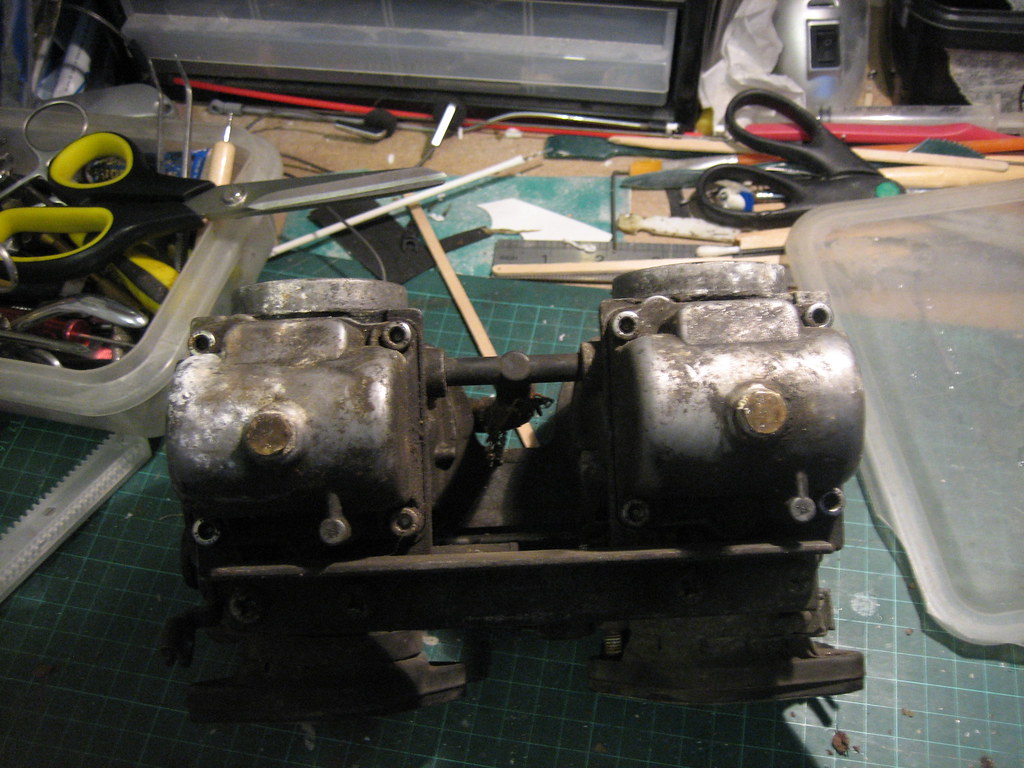

The carbs before...........

Carbs after, much better!!! No more black fingers when I pick them up!

Right, so after a few hiccups and setbacks, I have managed to start something on my bike!

I'm not trying to restore the bike, nor am I doing a proper build. At this moment in time I just want to get it going so I can sort out all the troubles and niggles before I go ahead and do a proper build! So I will be using whatever I can get cheaply! There are quite a few bits missing and rusted up, so I will be sourcing and replacing bits as I go along, as my budget is very tight!

I started off with the carbs, as I thought it would be the easiest and simple to take apart and reassemble. I took lots of pictures before I started the clean up and tear down! To be honest, they are not super clean on the outside, but they are a lot cleaner than they were!

I also cleaned up the tops,and painted the brackets.

Took the insides out, and cleared all the holes and had to replace the diapragms on the one side so I decided to to do both. Got one of those without the slider on it as they are a lot cheaper. They are good quality and very robust, and they are so easy to install! Needles and floats all seem ok so I left them as is, until I get the motor put together and running.

This week I took the fro!nt forks apart and stripped and cleaned them. I was going to lower the forks,but I will do that at a later stage. No serious mods so I can see what she's like "factory fresh"

On to some pics!!

The PO did this to the tank, the missus said she has to go!!

Couple of boxes!!

The carbs before...........

Carbs after, much better!!! No more black fingers when I pick them up!

Last edited: