desertrider

XS650 Member

Hi - I am putting my top end back together. I sent the head out to a good shop and had a valve job etc. done. Old intake valves were not good, so the shop bought 2 new valves (from Mikesxs, I believe) and returned parts to me. I bought a new spring/cap set from Mikesxs.

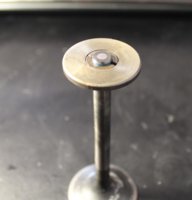

Now I am assembling the head, and have noticed that the new combo of valve, keepers, and cap result in the top of the valve being flush with the spring cap - not good.

I measured some combinations and found the top of the valve to protrude ABOVE the spring cap by this amount:

old cap, keepers,intake valve: + .040

old cap, keepers, new intake valve: +.040

old cap, new keepers, new intake valve: +.020

new cap, keeper, old valve: +.040

new cap, keepers, intake valve: FLUSH

The cap IDs are:

old: .162

new: .168

After looking this over, it seems the valve is the variable that causes the problem.

Any experience with this?

Suggestions to make the new valves (already ground to fit head) work?

Thank you!

Now I am assembling the head, and have noticed that the new combo of valve, keepers, and cap result in the top of the valve being flush with the spring cap - not good.

I measured some combinations and found the top of the valve to protrude ABOVE the spring cap by this amount:

old cap, keepers,intake valve: + .040

old cap, keepers, new intake valve: +.040

old cap, new keepers, new intake valve: +.020

new cap, keeper, old valve: +.040

new cap, keepers, intake valve: FLUSH

The cap IDs are:

old: .162

new: .168

After looking this over, it seems the valve is the variable that causes the problem.

Any experience with this?

Suggestions to make the new valves (already ground to fit head) work?

Thank you!

Attachments

Last edited: