-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Not reaching top speed

- Thread starter Bjorn

- Start date

Bjorn

XS650 Addict

@gary, do they extend into the exhaust port in the head? I found some very detailed topics about exhaust systems in general but also for our bike. The more I read the more i realize how complicated it is.

Here is some new info from some tests i did today. First I removed the baffles. Jeez they were tight. Some fabricoblin and good use of a truck crankpin and I got them out!

Holy crap it's loud without the baffles. A small testride sure but I can't use this set-up as final.

Ok and now for the results. First of all I realized how freaking slow my bike was around 5k rpm! Although the fueling isn't perfect I can really feel the difference in pulling power from 5k>. In 3rd and 4th gear it pull pretty quickly from 5 to 6,5k. I did some top speed runs and there is improvement. Now I reached 145 kmh (90mph) in 4th gear. 5th doesn't add speed.

I used my phone to shoot some quick VJO's

Here is some new info from some tests i did today. First I removed the baffles. Jeez they were tight. Some fabricoblin and good use of a truck crankpin and I got them out!

Holy crap it's loud without the baffles. A small testride sure but I can't use this set-up as final.

Ok and now for the results. First of all I realized how freaking slow my bike was around 5k rpm! Although the fueling isn't perfect I can really feel the difference in pulling power from 5k>. In 3rd and 4th gear it pull pretty quickly from 5 to 6,5k. I did some top speed runs and there is improvement. Now I reached 145 kmh (90mph) in 4th gear. 5th doesn't add speed.

I used my phone to shoot some quick VJO's

I think part of the problem is your gearing. You have to realize we're only dealing with about a 50 HP machine here. Gear it too high and it won't pull to redline in 5th. Personally, I wouldn't go any smaller than a 32T on an 18" rear wheel, and I don't even really like that size. I feel a 33T is ideal.

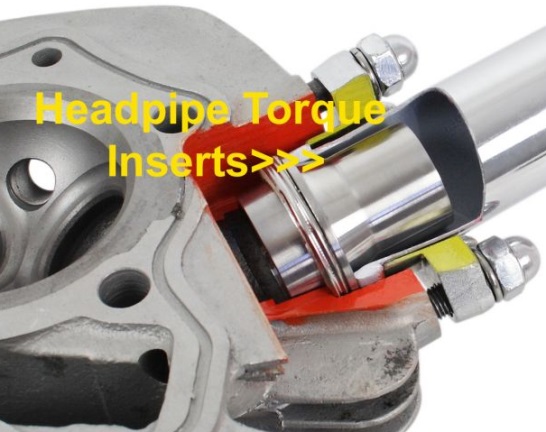

I do think you should experiment with the AR inserts too. They made mine with 1.5" pipes rev out much faster and better. I was surprised but obviously happy with the improvement. When I made my inserts, it wasn't for the "AR" aspect but rather as a way to more securely mount up my aftermarket headpipes. They didn't fit and seal well. The inserts solved that issue and I apparently gained some "AR" benefits in the process.

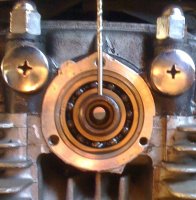

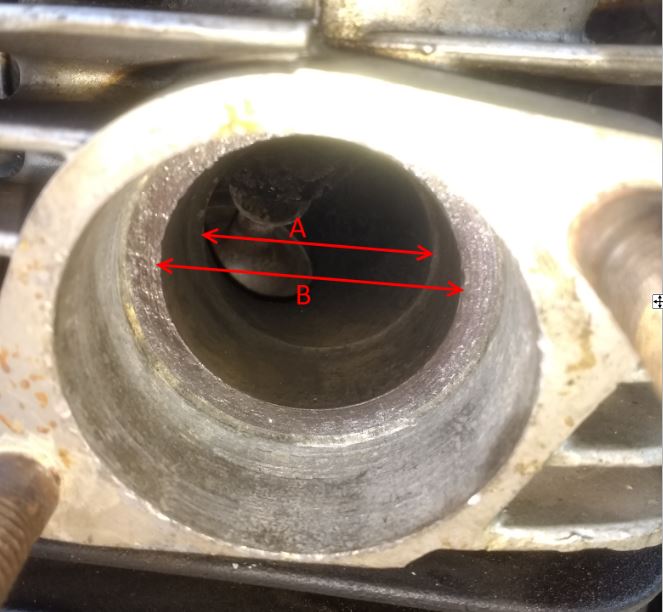

Now let's talk about the AR insert and something else you can do while fitting it. There is a rather deep step machined into the exhaust port to accept the end of the stock headpipe. It's deeper than it needs to be, and with the thick exhaust gasket on the pipe, the step never gets filled completely even with the pipe tightened down. This leaves a groove around the port and this is supposed to be detrimental to flow. Here's a pic of the MikesXS insert and you can clearly see the groove in the port that remains .....

We want to fill that groove but it's not possible with the parts assembled as above because it's width will constantly change depending on the amount of exhaust gasket compression. The solution is to install the insert first, directly into the head and step, then place the exhaust gasket and pipe over it. Then a pipe filler ring can be added or in your case, you could make the section of the AR insert that sticks into the head just long enough to fill the step. In my case, the insert was already made so I needed a filler ring .....

And this is how mine goes together - filler ring and insert directly into the head, then the exhaust gasket and pipe on top of them. I stick the insert into the head with some Yamabond to seal it .....

I do think you should experiment with the AR inserts too. They made mine with 1.5" pipes rev out much faster and better. I was surprised but obviously happy with the improvement. When I made my inserts, it wasn't for the "AR" aspect but rather as a way to more securely mount up my aftermarket headpipes. They didn't fit and seal well. The inserts solved that issue and I apparently gained some "AR" benefits in the process.

Now let's talk about the AR insert and something else you can do while fitting it. There is a rather deep step machined into the exhaust port to accept the end of the stock headpipe. It's deeper than it needs to be, and with the thick exhaust gasket on the pipe, the step never gets filled completely even with the pipe tightened down. This leaves a groove around the port and this is supposed to be detrimental to flow. Here's a pic of the MikesXS insert and you can clearly see the groove in the port that remains .....

We want to fill that groove but it's not possible with the parts assembled as above because it's width will constantly change depending on the amount of exhaust gasket compression. The solution is to install the insert first, directly into the head and step, then place the exhaust gasket and pipe over it. Then a pipe filler ring can be added or in your case, you could make the section of the AR insert that sticks into the head just long enough to fill the step. In my case, the insert was already made so I needed a filler ring .....

And this is how mine goes together - filler ring and insert directly into the head, then the exhaust gasket and pipe on top of them. I stick the insert into the head with some Yamabond to seal it .....

Bjorn

XS650 Addict

That's some great info 5twins! I'm going to use this for my inserts!

About the gearing, I'm using a 17 & 31 teeth sprocket. Should it not be able to reach its redline with this gearing?

This is the topic I red last week:

http://www.xs650.com/threads/650-ce...izers-and-torque-peak-optimizers.25438/page-2

Some good info although it being complicated. The things I picked up:

That being said, I do really want to keep the general pipe layout I have now. I really like it design wise and it's something different that what u usually see. I'm not sure how I'm supposed to improve the first bends of my exhaust. I might be able to smooth it out a bit. If I look at other pipes on the internet, I don't think my headers are that far off.

My bike:

Vs internet pipes:

This pipe inspired me to make my own. I don't know the details about these muffles.

Talking about those things, I'm pretty clueless right now. I know my current set-up with the baffles doesn't work. I need something that does work! And not be mega loud so I can ride wo being pulled over all the time.

Did find this design baffles:

About the gearing, I'm using a 17 & 31 teeth sprocket. Should it not be able to reach its redline with this gearing?

This is the topic I red last week:

http://www.xs650.com/threads/650-ce...izers-and-torque-peak-optimizers.25438/page-2

Some good info although it being complicated. The things I picked up:

- Try to make the first 6" from the exhaust valve into the pipe as "one" a bit like 5twins described.

- So I might need to extend the first bits of my pipes before the make a bend.

- Make the first bend as large of a radi as possible. They recommend 6" radi or more.

- I read a lot about "stepping" the pipes.

- I don't read a lot about baffles haha.

- Use trial and error.

That being said, I do really want to keep the general pipe layout I have now. I really like it design wise and it's something different that what u usually see. I'm not sure how I'm supposed to improve the first bends of my exhaust. I might be able to smooth it out a bit. If I look at other pipes on the internet, I don't think my headers are that far off.

My bike:

Vs internet pipes:

This pipe inspired me to make my own. I don't know the details about these muffles.

Talking about those things, I'm pretty clueless right now. I know my current set-up with the baffles doesn't work. I need something that does work! And not be mega loud so I can ride wo being pulled over all the time.

Did find this design baffles:

Bjorn, great progress. Glad that you're able to absorb some of this arcane stuff.

Another thing I'd like for you to do. A simple check of your camshaft timing.

The right side of the cam has a hole for a short 3mm indexing pin, that drives the advance unit for the points ignitions.

The TCI bikes have nothing in there.

A small straw or toothpick can be put in that hole.

Rotate the engine so that toothpick points perfectly straight up, right thru the middle of the camcover screw above it.

That's the camshaft's TDC.

Now, take a pic of the rotor's timing mark, and post it.

Looking to see if there's significant camchain stretch...

Another thing I'd like for you to do. A simple check of your camshaft timing.

The right side of the cam has a hole for a short 3mm indexing pin, that drives the advance unit for the points ignitions.

The TCI bikes have nothing in there.

A small straw or toothpick can be put in that hole.

Rotate the engine so that toothpick points perfectly straight up, right thru the middle of the camcover screw above it.

That's the camshaft's TDC.

Now, take a pic of the rotor's timing mark, and post it.

Looking to see if there's significant camchain stretch...

Last edited:

You may not be able to reach redline in 5th with your gearing, especially with the possible exhaust reversion issue you're having. One or two teeth difference on the rear sprocket may not seem like much but it makes a big difference on these bikes. Personally, I think you're geared too high. You will hear from some guys that their bike pulls the higher gearing just fine but what they may not be telling you is they're riding a stripped down bobber that could weigh as much as 100 lbs less than stock.

I think the length of your headpipes at the head looks fine and not too short before they bend. I would go ahead and make up the AR inserts, and see if they help. Mine are a bit short, but like I said, I really wasn't making AR inserts, just better headpipe mounts. So, you could make yours a bit longer, like some of the ones Gary shows or the MikesXS ones, so they extend into the pipe more.

I think the length of your headpipes at the head looks fine and not too short before they bend. I would go ahead and make up the AR inserts, and see if they help. Mine are a bit short, but like I said, I really wasn't making AR inserts, just better headpipe mounts. So, you could make yours a bit longer, like some of the ones Gary shows or the MikesXS ones, so they extend into the pipe more.

A 17/30 sprocket combo makes 4th almost the same as the original 5th.

A 17/31 sprocket combo makes 4th just a tad lower than 5th, and should hit redline.

A 17/31 sprocket combo makes 4th just a tad lower than 5th, and should hit redline.

Exhaust Information given to XSclub Australia for their Race bike.....Micheal Morse from 650 central provided this for us.

http://www.xs650.org.au/Technical Info/exhaust_port.htm

http://www.xs650.org.au/Technical Info/exhaust_port.htm

Bjorn

XS650 Addict

Yesterday I was talking to a friend about my exhaust project here. He had a good and easy recommendation: retest at stationary to see if you get blowback from the carbs with the baffles removed. So I tried:

Now I revved it twice, first time looks quite similar to my original results, second time there appears to be less blowback. But it still doesn't look as it should I guess.

I'll ttry the cam timing tip next. I did replace the chain when I rebuild this motor around 5000 km ago..

Regarding the AR cones. I can't really find dimensions or topics where people with 1,5 inch pipes run them. Only from 1 3/4 can I find some info

Now I revved it twice, first time looks quite similar to my original results, second time there appears to be less blowback. But it still doesn't look as it should I guess.

I'll ttry the cam timing tip next. I did replace the chain when I rebuild this motor around 5000 km ago..

Regarding the AR cones. I can't really find dimensions or topics where people with 1,5 inch pipes run them. Only from 1 3/4 can I find some info

Bjorn

XS650 Addict

Bjorn, great progress. Glad that you're able to absorb some of this arcane stuff.

Another thing I'd like for you to do. A simple check of your camshaft timing.

The right side of the cam has a hole for a short 3mm indexing pin, that drives the advance unit for the points ignitions.

View attachment 135645

The TCI bikes have nothing in there.

A small straw or toothpick can be put in that hole.

View attachment 135630

Rotate the engine so that toothpick points perfectly straight up, right thru the middle of the camcover screw above it.

View attachment 135631

That's the camshaft's TDC.

Now, take a pic of the rotor's timing mark, and post it.

Looking to see if there's significant camchain stretch...

I just tried this. It's hard to get the hole in the camshaft exactly in the middle. Because the hole in mine is blind... It's only like 1mm deep. Can't really put anything in there.

Anyway keep that in mind, here are the pics

Another way to check camshaft position accurately is to lock the crank at TDC, jam fit a line in the hole in the end of the crankshaft, and pull the line up across the center of the camshaft. The hole in the camshaft should match up with the line.

Valve timing appears to be advanced. This could be caused by a thick head gasket like the one sold by Athena (.060" thick as opposed to .043" for OE spec). But before you assume anything about timing, note that the timing mark on your stator is on a movable plate. Verify that the plate is in the right position by locating true top dead center (plenty of threads on this, search and you will find). Also check ignition timing with a strobe; even a little bit of error to the advance side can cause a holed piston, and most of us find that things work better with ignition timing slightly retarded..

Valve timing appears to be advanced. This could be caused by a thick head gasket like the one sold by Athena (.060" thick as opposed to .043" for OE spec). But before you assume anything about timing, note that the timing mark on your stator is on a movable plate. Verify that the plate is in the right position by locating true top dead center (plenty of threads on this, search and you will find). Also check ignition timing with a strobe; even a little bit of error to the advance side can cause a holed piston, and most of us find that things work better with ignition timing slightly retarded..

Good, you're getting some reactions from your changes. On your cam timing, I was looking for something way out of normal, but don't see anything outrageous.

Interesting that the spitback fog occurred 1st, but not 2nd.

Could be just an audio thing, but the engine/intake/exhaust sound at high rpm sounds strained, a raspy flavor. Almost like the valves are floating, or sticking...

Interesting that the spitback fog occurred 1st, but not 2nd.

Could be just an audio thing, but the engine/intake/exhaust sound at high rpm sounds strained, a raspy flavor. Almost like the valves are floating, or sticking...

I don't think the AR dimensions for 1.5" pipes would differ much, except for the slightly smaller O.D. on the part that inserts into the pipe. On the ones I made from old stock headpipe ends, I had to peel off the outer layer of the double wall pipe and then do a little filing to get them to slip into my 1.5" pipes. Mine revved better (quicker and easier) once I installed the inserts. I'm sure some of that was due to better sealing the pipes to the head, but some of it could be related to the "AR" thing.

Right, 5twins, AR dimensions are pretty much constant. Michael Morse offers the same exhaust port inserts for both 1.5" and 1.75" pipes. His design is a touch more sophisticated (made to tuned length and outlets radiused, for example) but before I bought a pair of those some years ago I used your recipe with good results. It's a good use for crusty old pipes that are beyond redemption.

Bjorn

XS650 Addict

Got a practical question regarding the exhaust port diameters. I dont have the right measuring equipment to measure the inside diameter of the steps in the exhaust port. Does anyone have these dimensions of know where i can find them?

I believe "B" is 38-39mm...

Bjorn

XS650 Addict

Found a perfect tool to measure the inner bore of the port.... It's to big to measure haha. Gotta try something else .

I also checked the timing. Borrowed a strobe from a friend to check it. Here is my set-up:

Stand alone batt . Around 12,4volts

Hooked up to the LHS lead.

I filmed it with a GoPro at 100fps but it's hard to get a decent shot.

At idle the rotor mark imark is between the fork mark |_| on the stator but a bit on the left side of it. Now when I rev it up, the mark moves counter clockwise. I red in the forum it should move clockwise? I'm confused.

Secondly, Don't know if it's the strobe, but I could tell every now and then it would not flash. not sure if that it the bike or not.

I also checked the timing. Borrowed a strobe from a friend to check it. Here is my set-up:

Stand alone batt . Around 12,4volts

Hooked up to the LHS lead.

I filmed it with a GoPro at 100fps but it's hard to get a decent shot.

At idle the rotor mark imark is between the fork mark |_| on the stator but a bit on the left side of it. Now when I rev it up, the mark moves counter clockwise. I red in the forum it should move clockwise? I'm confused.

Secondly, Don't know if it's the strobe, but I could tell every now and then it would not flash. not sure if that it the bike or not.

Bjorn

XS650 Addict

O forgot to add that after the first test, I hooked up my second TCI box to see what it does:

Exactly the same as the first one! I also tried the RHS lead but that wasn't working at all.

Exactly the same as the first one! I also tried the RHS lead but that wasn't working at all.

It's not advancing at all.

That would certainly keep you from getting top speed.

The video in post #1 shows what to expect.

http://www.xs650.com/threads/an-led-ignition-timing-light-experiment.44586/

That would certainly keep you from getting top speed.

The video in post #1 shows what to expect.

http://www.xs650.com/threads/an-led-ignition-timing-light-experiment.44586/

Bjorn

XS650 Addict

Thanks for that video! I'm not seeing that at all on my bike!

Two questions: how am I accelerating at all when I ride??

And secondly, what is the chance both TCI are faulty (had one repaired last year)

Two questions: how am I accelerating at all when I ride??

And secondly, what is the chance both TCI are faulty (had one repaired last year)