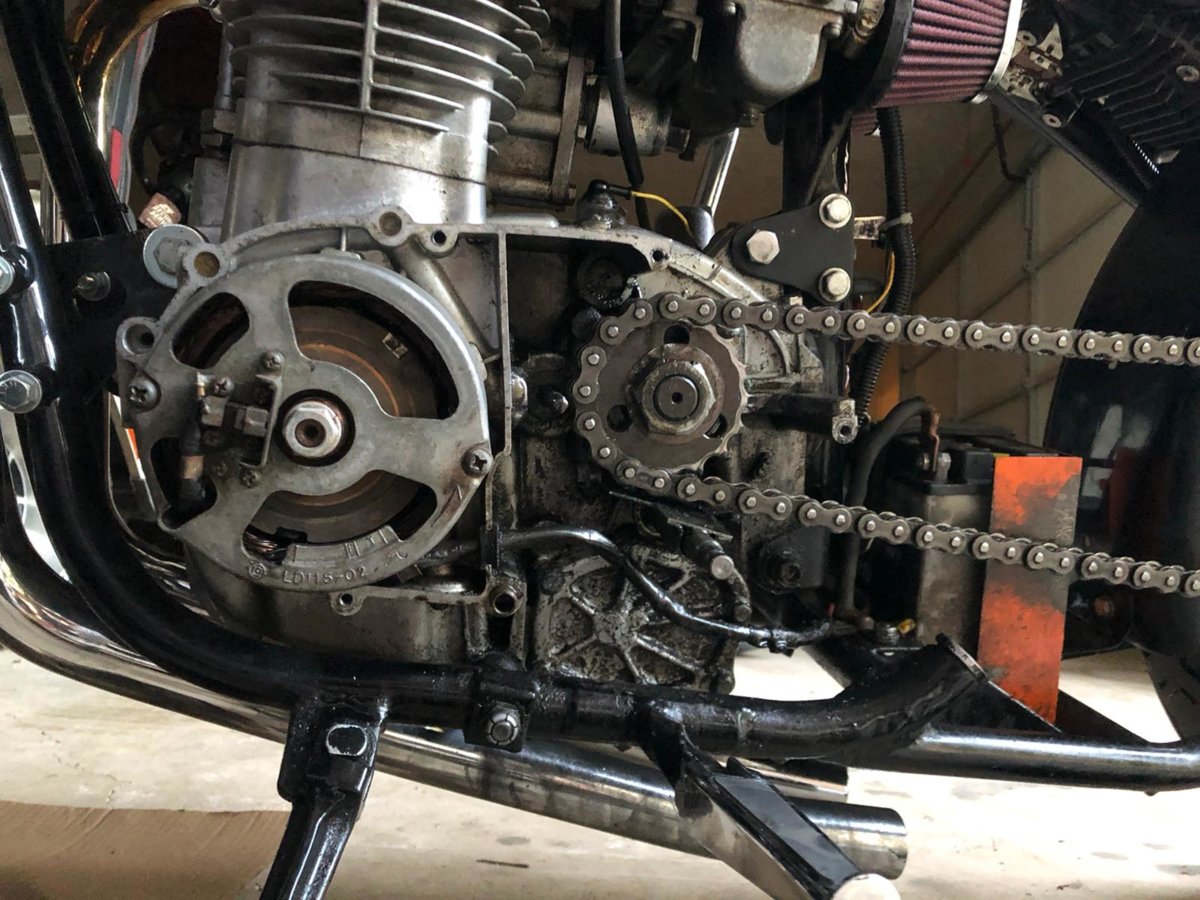

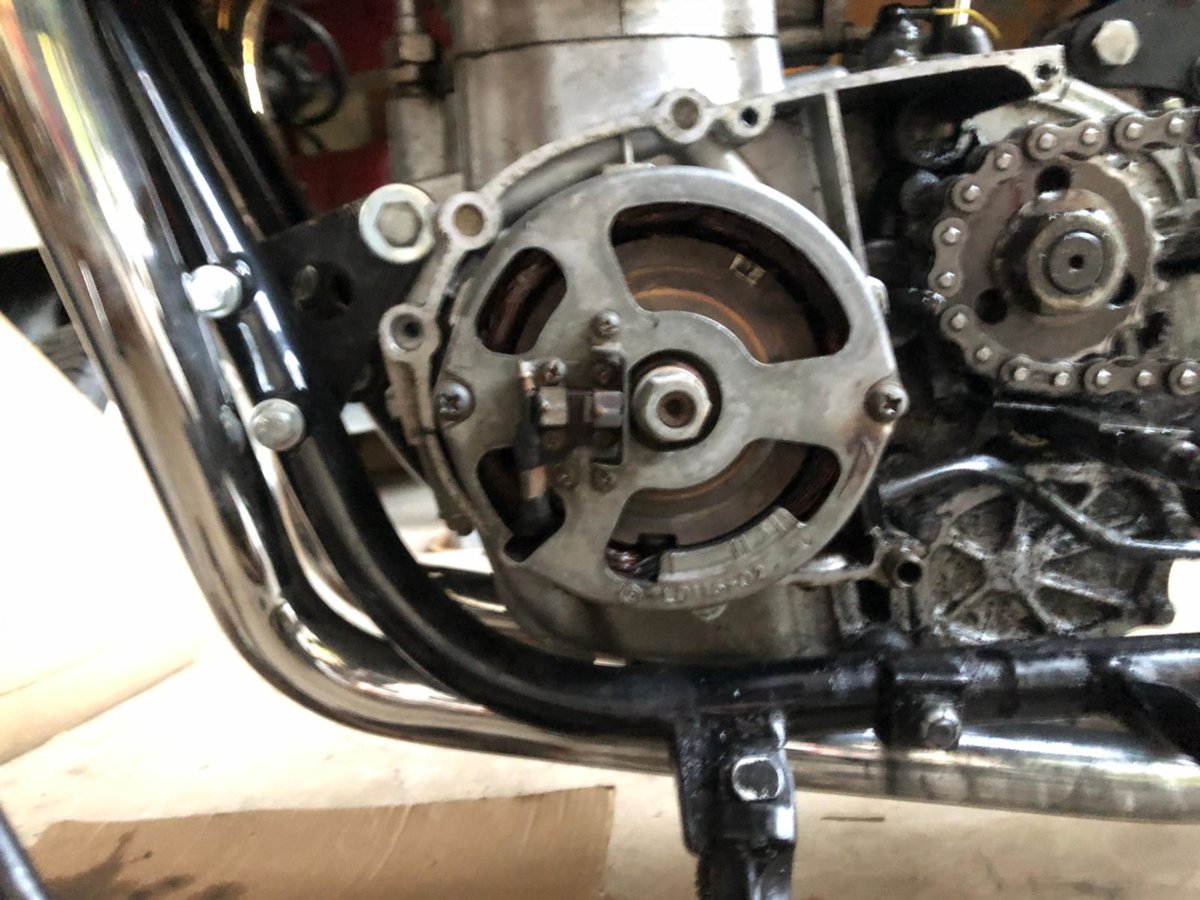

How it going y'all i have recently bought a steal of a deal on a 1972 XS650, but the biggest problem is I have little to no experience with bikes but I like the journey that awaits, and I'm trying to dive in. Of coarse I'm slowly finding more issues that where not mentioned, like two oil leaks I'm trying to figure out with the help of posts from this page of coarse. I have found out my clutch push oil seal is one of the culprits if not the main. I have a couple photos ill post and was hoping if anyone could help me out and see if they noticed anything else i should be worried about while I'm down here. also threw in my recent purchase, hope to hear from some of y'all soon

some of y'all soon

some of y'all soon