From the serial number, that looks to be a 1972 motor.

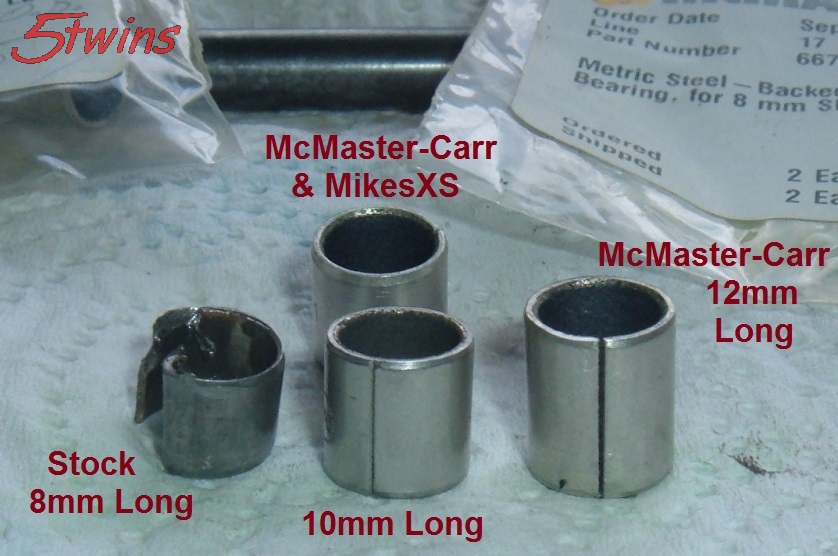

The description of your pushrod bushing problems is rather vague, like saying "bushings" - there's only one. The bushing can be had in different lengths but the 10mm O.D. and 8mm I.D. will always be the same. Longer is considered better. It will support the pushrod better (more) and shouldn't wear out as quickly .....

The description of your pushrod bushing problems is rather vague, like saying "bushings" - there's only one. The bushing can be had in different lengths but the 10mm O.D. and 8mm I.D. will always be the same. Longer is considered better. It will support the pushrod better (more) and shouldn't wear out as quickly .....