LOL.......thanks TM. Guess you'll get this reply on the next fly by. Fingers and Toes crossed. Have a great trip and ride safe!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

On the road again at 40.............the bike that is

Well…..Mailman…….have our bikes been talking to each other or sumthin?

After losing almost a month of some really good riding weather waiting on my machinist to fix my 2 carb sets, I finally caved and picked up another set of 78/79 BS38’s. Probably cost me a lot less than what my machining costs will be and figured having a spare set of good working 78/79’s on the shelf ain't a bad thing. (If I can achieve that)

I'm (almost) at the point of admitting that I might have a problem and may be in need of an intervention.

"My name is robinc and I am a carbaholic".

I had the benefit of a mental health day earlier last week so tore this set down, cleaned, replaced o-rings, new OEM float bowl gaskets, bench synced, diaphragms strong, don't even drop. No damage to this set other than a bent choke lever that I straightened. However one of the floats was leaking so ordered a couple from XS650Direct knowing I could get them in a couple days. Have since learned from some other recent carb threads lately that they are still available OEM so will get them if these prove to be inferior.

After work Friday installed new floats, reassembled and used my remote tank stand/bench top float level checker thingamajig. Funny how the level shows a little low, they are set to 24mm from the gasket surface, and are not twisted. I checked, checked, checked and re-checked. Well I figured better a little low than a little high.

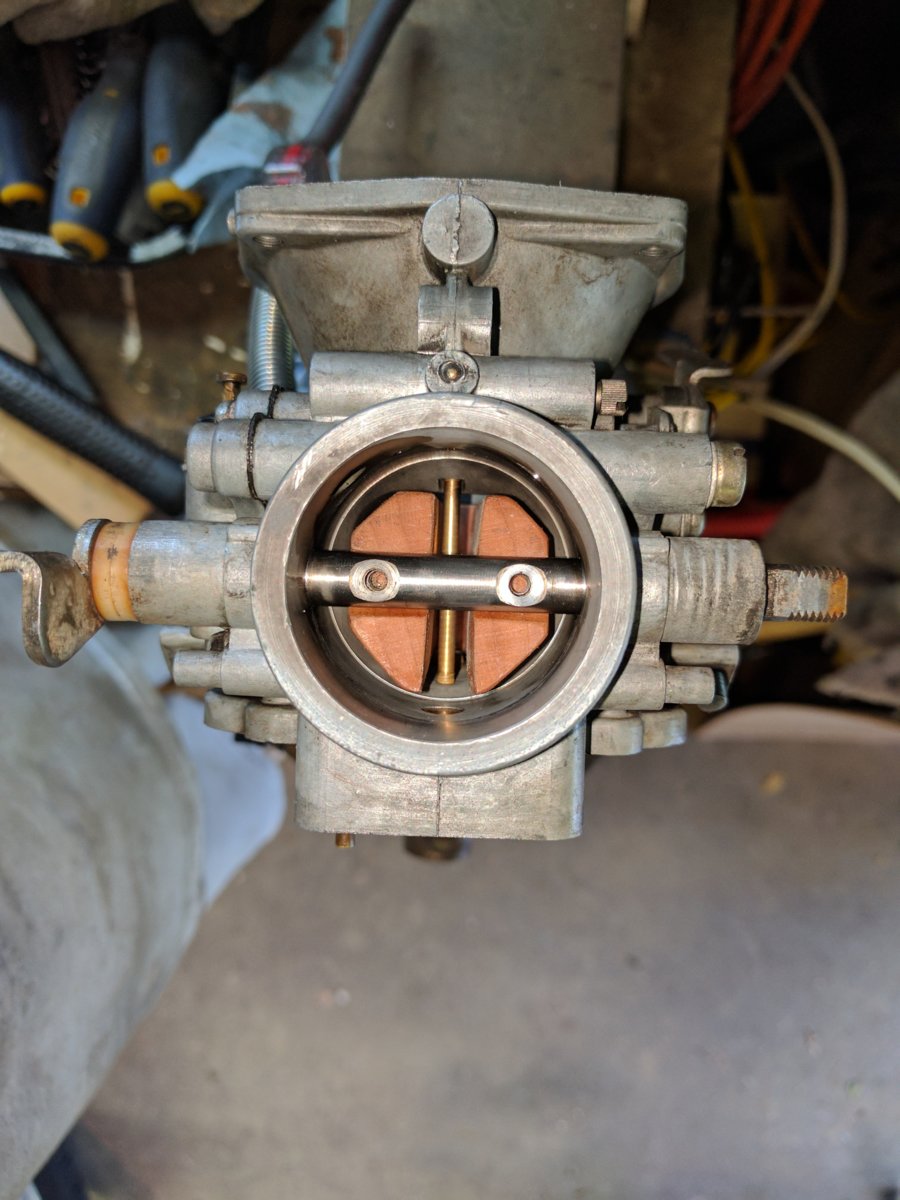

Started easy, 2 kicks, idled great, revved great, butterflies moved smoothly, no binding, but (why does there always have to be a but) within 2 or 3 minutes it was obvious from the wonky hanging idle that the throttle shaft seals were leaking. Got out the carb cleaner and yup, sure enough.

Off they come again.

Looks like Mailman and I spent our Saturday the same way, in carb surgery. We should have done one of Pete's famous video chats……..lol.

I'm sure thankful for this thread by gggGary:

http://www.xs650.com/threads/carb-t...ft-butterfly-screw-removal.46423/#post-464664

that gave me the idea for my little 'Stick it’. (see post #41) Made the job of removing those throttle shaft screws easy.

You can see how these seals are deformed and cracked, really dried out and hard.

Ran out of shop time so remounted on Sunday.

Fired up easy again, couple kicks, no more wonky idle, revved up nice, but it was raining so couldn't get out for a test drive.

Due to unforeseen circumstances only worked a half day today. Normally I wouldn't be happy about losing half a day but with a bike to test drive, OK.

Fired up first kick, and continues to do so.

Half way through a short ½ hour ride, throttle shaft leak symptoms reappeared. Huh? Just put new ones in 2 days ago. (C facing out)

Bike back in shop, sprayed WD40 on right side throttle shaft end, idle increased, no effect on choke assemblies. Sprayed on inner seals, idle increased. No effect on left outer seal. Got one right.

If I push on either end of the throttle shaft, idle increases.

I know Mailman is having trouble with his butterflies hanging open, not a problem with mine, operating smoothly. (So I thought) But I just read in Mailmans new “Carburetors hanging open” thread that Time machine and 5twins think it might be that his carbs aren't quite mounted properly in the brackets, thus causing his binding.

They, Scott and 2M suggest to install all springs and linkage before snapping butterflies closed and 2M recommends then applying some pressure to the staked throttle shaft washer while tightening throttle shaft butterfly screws. I didn't do that, tightened screws with butterflies positioned without springs etc. I also just noticed that my left side throttle shaft nut had come loose. If I tighten the nut right down, butterflies bind, so maybe there is air leaking in the seals due to the nylon throttle shaft washers not being fully seated? (Although you would think the vacuum would pull them in. Maybe not if the washers aren't fully seated)

I think I may have been my own worst enemy here by not reassembling properly thus causing 2 problems, air leak, and butterfly binding if I try to tighten enough to solve air leak.

So…... got another ½ hour ride in this month. (At this rate I'm way overpaying for insurance, but, not spending a lot on gas)

Coming off again, but don't know when I'll find the time. Hopefully properly centering butterflies with all springs and linkage installed and a little push will solve the problem. Blue LOCTITE says 'REMOVABLE’, sure hope so.

Fingers crossed, I'm spending money on carbs like a drunken sailor and sure am chasing my tail on this.

Boy, Bob, I sure wish now your thread had come a few days earlier…...lol.

Any suggestions or recommendations gratefully received.

After losing almost a month of some really good riding weather waiting on my machinist to fix my 2 carb sets, I finally caved and picked up another set of 78/79 BS38’s. Probably cost me a lot less than what my machining costs will be and figured having a spare set of good working 78/79’s on the shelf ain't a bad thing. (If I can achieve that)

I'm (almost) at the point of admitting that I might have a problem and may be in need of an intervention.

"My name is robinc and I am a carbaholic".

I had the benefit of a mental health day earlier last week so tore this set down, cleaned, replaced o-rings, new OEM float bowl gaskets, bench synced, diaphragms strong, don't even drop. No damage to this set other than a bent choke lever that I straightened. However one of the floats was leaking so ordered a couple from XS650Direct knowing I could get them in a couple days. Have since learned from some other recent carb threads lately that they are still available OEM so will get them if these prove to be inferior.

After work Friday installed new floats, reassembled and used my remote tank stand/bench top float level checker thingamajig. Funny how the level shows a little low, they are set to 24mm from the gasket surface, and are not twisted. I checked, checked, checked and re-checked. Well I figured better a little low than a little high.

Started easy, 2 kicks, idled great, revved great, butterflies moved smoothly, no binding, but (why does there always have to be a but) within 2 or 3 minutes it was obvious from the wonky hanging idle that the throttle shaft seals were leaking. Got out the carb cleaner and yup, sure enough.

Off they come again.

Looks like Mailman and I spent our Saturday the same way, in carb surgery. We should have done one of Pete's famous video chats……..lol.

I'm sure thankful for this thread by gggGary:

http://www.xs650.com/threads/carb-t...ft-butterfly-screw-removal.46423/#post-464664

that gave me the idea for my little 'Stick it’. (see post #41) Made the job of removing those throttle shaft screws easy.

You can see how these seals are deformed and cracked, really dried out and hard.

Ran out of shop time so remounted on Sunday.

Fired up easy again, couple kicks, no more wonky idle, revved up nice, but it was raining so couldn't get out for a test drive.

Due to unforeseen circumstances only worked a half day today. Normally I wouldn't be happy about losing half a day but with a bike to test drive, OK.

Fired up first kick, and continues to do so.

Half way through a short ½ hour ride, throttle shaft leak symptoms reappeared. Huh? Just put new ones in 2 days ago. (C facing out)

Bike back in shop, sprayed WD40 on right side throttle shaft end, idle increased, no effect on choke assemblies. Sprayed on inner seals, idle increased. No effect on left outer seal. Got one right.

If I push on either end of the throttle shaft, idle increases.

I know Mailman is having trouble with his butterflies hanging open, not a problem with mine, operating smoothly. (So I thought) But I just read in Mailmans new “Carburetors hanging open” thread that Time machine and 5twins think it might be that his carbs aren't quite mounted properly in the brackets, thus causing his binding.

They, Scott and 2M suggest to install all springs and linkage before snapping butterflies closed and 2M recommends then applying some pressure to the staked throttle shaft washer while tightening throttle shaft butterfly screws. I didn't do that, tightened screws with butterflies positioned without springs etc. I also just noticed that my left side throttle shaft nut had come loose. If I tighten the nut right down, butterflies bind, so maybe there is air leaking in the seals due to the nylon throttle shaft washers not being fully seated? (Although you would think the vacuum would pull them in. Maybe not if the washers aren't fully seated)

I think I may have been my own worst enemy here by not reassembling properly thus causing 2 problems, air leak, and butterfly binding if I try to tighten enough to solve air leak.

So…... got another ½ hour ride in this month. (At this rate I'm way overpaying for insurance, but, not spending a lot on gas)

Coming off again, but don't know when I'll find the time. Hopefully properly centering butterflies with all springs and linkage installed and a little push will solve the problem. Blue LOCTITE says 'REMOVABLE’, sure hope so.

Fingers crossed, I'm spending money on carbs like a drunken sailor and sure am chasing my tail on this.

Boy, Bob, I sure wish now your thread had come a few days earlier…...lol.

Any suggestions or recommendations gratefully received.

TimeMachine

SeventyEighte

"Carboholic robinc" your work bench signs say it all ! Im onto you and Mailman now. There's prob nuttin wrong with you twos' carbs and you two are really puttin on the carb show ! Aye ayay

Ah TM, I wish it were so......lol. Got any 'working' 78/79 BS38's kicking around?

Robin , I like your style. That is quite the set up you have there. I got a feeling you'll be in the carb rebuilding business soon! I am liking your carb stick, might have to make me one of those, I also like your float level checker. By the way, I am in the blue locktite camp. I have done that on several carburetors and it always worked out really well.

I also have a bad feeling that one of these days my new throttle shaft seals are going to fail also. I got them from Mikes XS and they don't have a very good reputation for durability. 5Twins has used and recommends some more robust solid seals sold by McMaster-Carr ( is that the right name?)

I have also thought about buying another set of carbs, mostly because of the wear in one of my bodies.

Sometimes it gets frustrating when your hard work ends in a set back, but when you finally solve a problem and are rewarded with a bike that idles perfectly, or charges the way it should, or doesn't drool oil on your floor. Well, it's just so much more rewarding than a new machine that has appliance like reliability. The level of involvement and subsequent reward makes it all worthwhile.

Hang in there buddy! Keep plugging away.

I also have a bad feeling that one of these days my new throttle shaft seals are going to fail also. I got them from Mikes XS and they don't have a very good reputation for durability. 5Twins has used and recommends some more robust solid seals sold by McMaster-Carr ( is that the right name?)

I have also thought about buying another set of carbs, mostly because of the wear in one of my bodies.

Sometimes it gets frustrating when your hard work ends in a set back, but when you finally solve a problem and are rewarded with a bike that idles perfectly, or charges the way it should, or doesn't drool oil on your floor. Well, it's just so much more rewarding than a new machine that has appliance like reliability. The level of involvement and subsequent reward makes it all worthwhile.

Hang in there buddy! Keep plugging away.

Thanks Bob, I appreciate your words of encouragement and am feeling your pain as well right now.

I have those McMaster-Carr seals (let me know if you want to try some, got a bag full, can send you some) but used Yamaha OEM seals #256-14497-00-00 after reading comments by retiredgentleman and seeing gggGarys advice that the Yamaha originals are better. I don't really know which are better in the final analysis but if I can get OEM parts I usually go that way by default. So, I don't think it's a poor seal quality problem, but rather the problem that I didn't assemble properly and get things tight enough.

Guess we'll see when I get the time to pull them and reset everything. Until then, my carb building business prospects look pretty bleak...lol.

Good luck with your carbs as well my friend.

I have those McMaster-Carr seals (let me know if you want to try some, got a bag full, can send you some) but used Yamaha OEM seals #256-14497-00-00 after reading comments by retiredgentleman and seeing gggGarys advice that the Yamaha originals are better. I don't really know which are better in the final analysis but if I can get OEM parts I usually go that way by default. So, I don't think it's a poor seal quality problem, but rather the problem that I didn't assemble properly and get things tight enough.

Guess we'll see when I get the time to pull them and reset everything. Until then, my carb building business prospects look pretty bleak...lol.

Good luck with your carbs as well my friend.

Rob, nice pics. I like the woodworking gadgets in the background.

Lemme see, I had 3 things on my mind.

1. Throttle shaft straightness. Another of my obsessions, precise straightness and true. My shafts looked straight, and seemed to roll fine on a flat plate. But, they didn't quite turn freely after I rebushed my carbs' shaft bores. Chucked up the shafts in the lathe, and found about 0.005" TIR. Imperceptible by eye, but was enuff to prevent free turning. Without a lathe, I suppose you could try to fit the shafts into a precision reamed bore, and see if they're straight. The only thing that comes to mind at the moment would be to use a new valve guide as a straightness checker.

2. Throttle shaft bores. I had to rebush mine.

http://www.xs650.com/threads/1971-xs1b-bs38-carbs-throttle-shaft-bushings.43326/

More discussion here (older thread):

http://www.xs650.com/threads/1971-carbs-throttle-shaft-caps-staked-on-how-to-remove.33692/

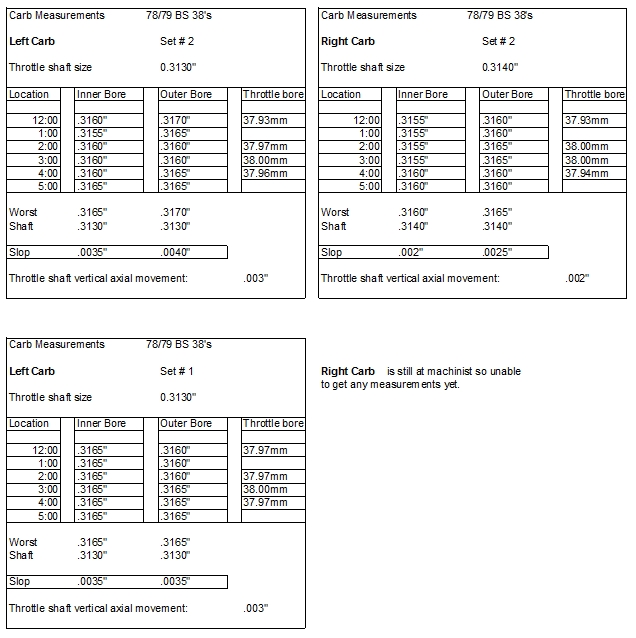

3. Out-of-round throttle bores. This is something I'm considering tackling on mine. I'd like to know if others have similar out-of-roundness, or if its just me. These pics show my measurements.

Click on a pic will take you to my album.

(Cool new feature of this new forum software)

Notice all the leakage around the sides of the butterfly valves.

This out-of-roundness thing really has me kinked. I don't know if this could be the result of years of heat cycles, with strain from weight and the spigot clamps, or a normal consequence of budget Zamak casting of the time. The changes to pilot jets and butterfly valves in the early 70-71 carbs feeds my suspicions. Maybe the later carbs don't have this quirk, and it's not a concern for you. I haven't found any info on chasing this problem...

Lemme see, I had 3 things on my mind.

1. Throttle shaft straightness. Another of my obsessions, precise straightness and true. My shafts looked straight, and seemed to roll fine on a flat plate. But, they didn't quite turn freely after I rebushed my carbs' shaft bores. Chucked up the shafts in the lathe, and found about 0.005" TIR. Imperceptible by eye, but was enuff to prevent free turning. Without a lathe, I suppose you could try to fit the shafts into a precision reamed bore, and see if they're straight. The only thing that comes to mind at the moment would be to use a new valve guide as a straightness checker.

2. Throttle shaft bores. I had to rebush mine.

http://www.xs650.com/threads/1971-xs1b-bs38-carbs-throttle-shaft-bushings.43326/

More discussion here (older thread):

http://www.xs650.com/threads/1971-carbs-throttle-shaft-caps-staked-on-how-to-remove.33692/

3. Out-of-round throttle bores. This is something I'm considering tackling on mine. I'd like to know if others have similar out-of-roundness, or if its just me. These pics show my measurements.

Click on a pic will take you to my album.

(Cool new feature of this new forum software)

Notice all the leakage around the sides of the butterfly valves.

This out-of-roundness thing really has me kinked. I don't know if this could be the result of years of heat cycles, with strain from weight and the spigot clamps, or a normal consequence of budget Zamak casting of the time. The changes to pilot jets and butterfly valves in the early 70-71 carbs feeds my suspicions. Maybe the later carbs don't have this quirk, and it's not a concern for you. I haven't found any info on chasing this problem...

Last edited:

Thank you 2M and thanks for your reply. Did a quick read through those threads, will spend more time there when done work.

It does appear that I am experiencing that pull up and to the left problem, so perhaps bushings are worn, or bent shaft problem, although there doesn't appear to be any slop or movement across throttle shaft axis, just longitudinally.

I tightened up throttle shaft screws with carbs apart and unconnected so now that all springs and linkage are in place, butterflies are binding.

I guess the quick fix to try for now is to break throttle shaft screws free and retighten properly as per your suggestions in Bob's thread.

Will give that a go and post results.

Thanks again and have a good one!

Edit: Back to get the links to those threads and noticed I didn't address your one point 2M.

My butterflies fit perfectly, no gaps when fully closed, so it looks like I miss this one at least. But in saying that I do think I might have that issue with my 74/75's. Will verify when I get them back from my machinist.

It does appear that I am experiencing that pull up and to the left problem, so perhaps bushings are worn, or bent shaft problem, although there doesn't appear to be any slop or movement across throttle shaft axis, just longitudinally.

I tightened up throttle shaft screws with carbs apart and unconnected so now that all springs and linkage are in place, butterflies are binding.

I guess the quick fix to try for now is to break throttle shaft screws free and retighten properly as per your suggestions in Bob's thread.

Will give that a go and post results.

Thanks again and have a good one!

Edit: Back to get the links to those threads and noticed I didn't address your one point 2M.

My butterflies fit perfectly, no gaps when fully closed, so it looks like I miss this one at least. But in saying that I do think I might have that issue with my 74/75's. Will verify when I get them back from my machinist.

Last edited:

I found those solid seals quite a few years back before I discovered originals were still readily and cheaply available from Yamaha. At that time I thought the only source was Mikes and they were $5 each. I was looking for a cheaper alternative, which I found, but I don't really use them anymore since originals can be had for a reasonable price. The carb set I put them in is working fine but it's one of my spare sets and doesn't see much use. I really can't say how well they'd hold up in daily use for the long term. If I were to use some now, I think I'd only put them on the outer sides where they could be easily changed out without pulling the shafts if they went bad.

Thanks for your reply 5twins. Good to know. I had picked them up after some site searching and found some of your posts then recently read about you finding originals are available so went that route.

We'll see how I make out readjusting properly.

Thanks for all you do here!

Take care.

We'll see how I make out readjusting properly.

Thanks for all you do here!

Take care.

If I read that you can get original throttle shaft seals still from Yamaha I forgot about it. That sounds like the way to go. Did you order yours online? Who from?

By the way, 2M continues to blow my mind after reading his carburetor build thread. I don't even own precision measuring devices. He approaches mechanical things as a machinist would. My only power tools are drills and saws, and for really delicate work my BFH!

By the way, 2M continues to blow my mind after reading his carburetor build thread. I don't even own precision measuring devices. He approaches mechanical things as a machinist would. My only power tools are drills and saws, and for really delicate work my BFH!

Hey Bob got mine from an approved Yamaha parts supplier, same shop doing my carbs. You should be able to get them from any Yamaha dealer.

I think the info re: availablity has only just surfaced in some more recent posts, after you did yours.

No kidding eh? 2M never ceases to amaze me, as with all the guru's with all their different specialties.

I have a few of those 'gentle persuaders' of various shapes and sizes....lol.

I think the info re: availablity has only just surfaced in some more recent posts, after you did yours.

No kidding eh? 2M never ceases to amaze me, as with all the guru's with all their different specialties.

I have a few of those 'gentle persuaders' of various shapes and sizes....lol.

First of all:

Ok, the question of the day is “how much slop is too much slop?”.

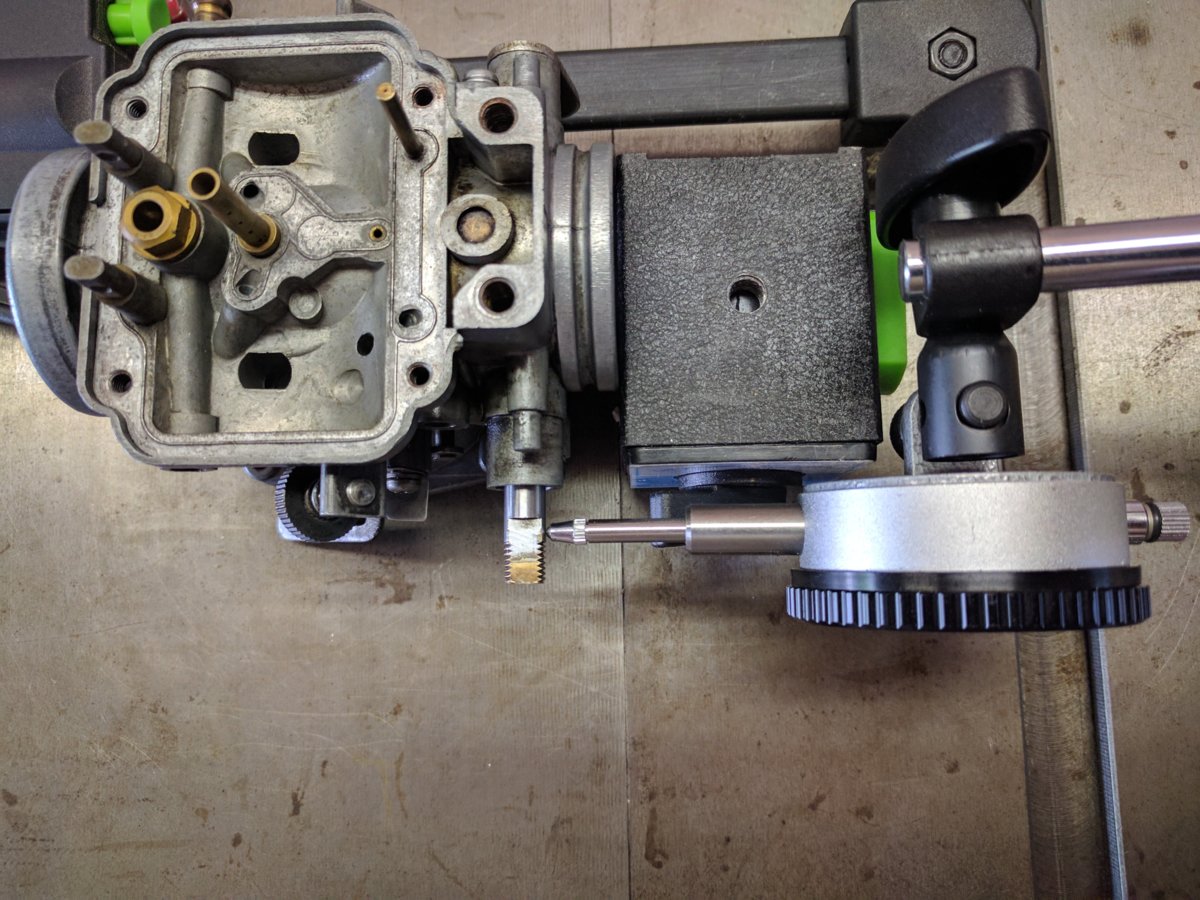

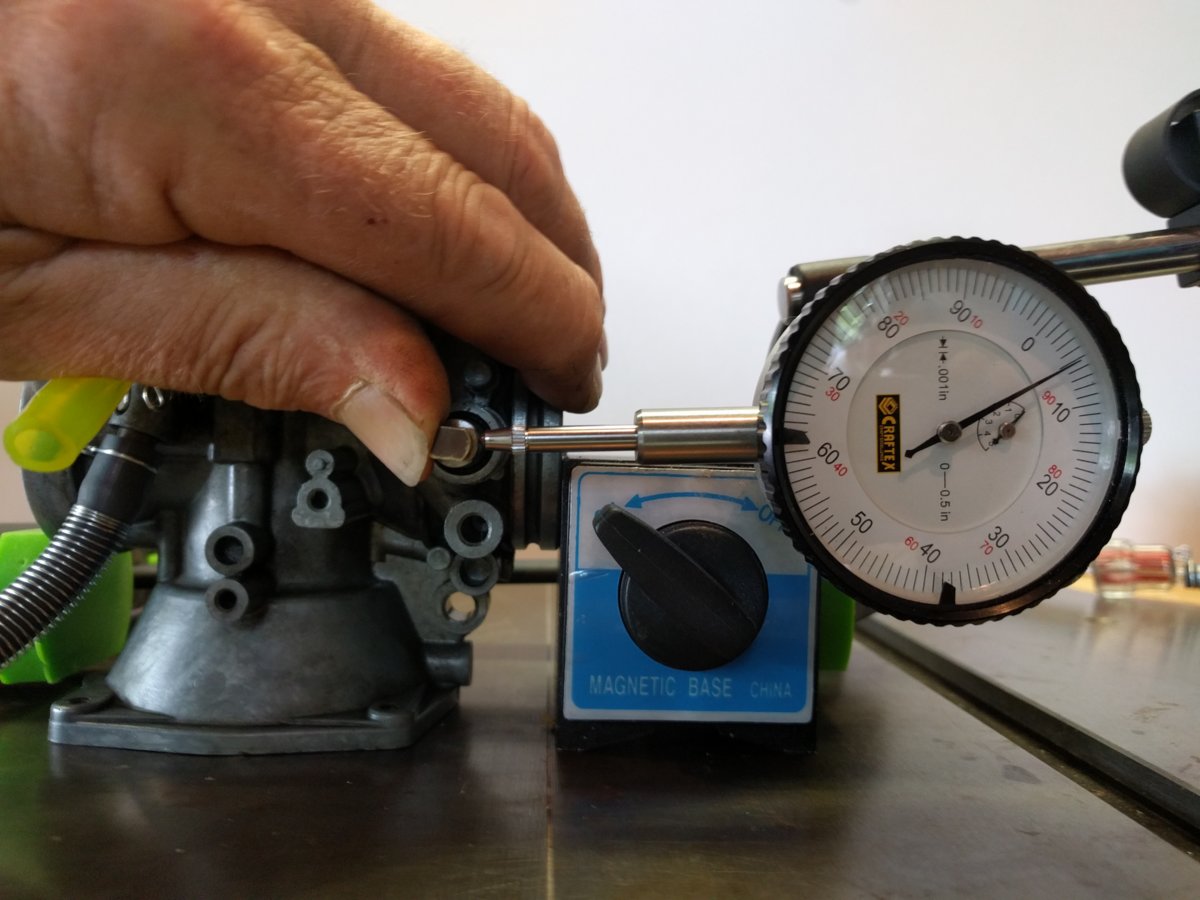

After reading through the above links kindly supplied by 2M, I decided to get some measurements similar to those done by him.

Can't insert an Excel spreadsheet so here is a screen capture:

2M in the first thread states:

So with mine being .0020" to .0040" I wonder how much less, and if these values are significant enough to allow seal air leaks and if they would indicate the need to replace bushings?

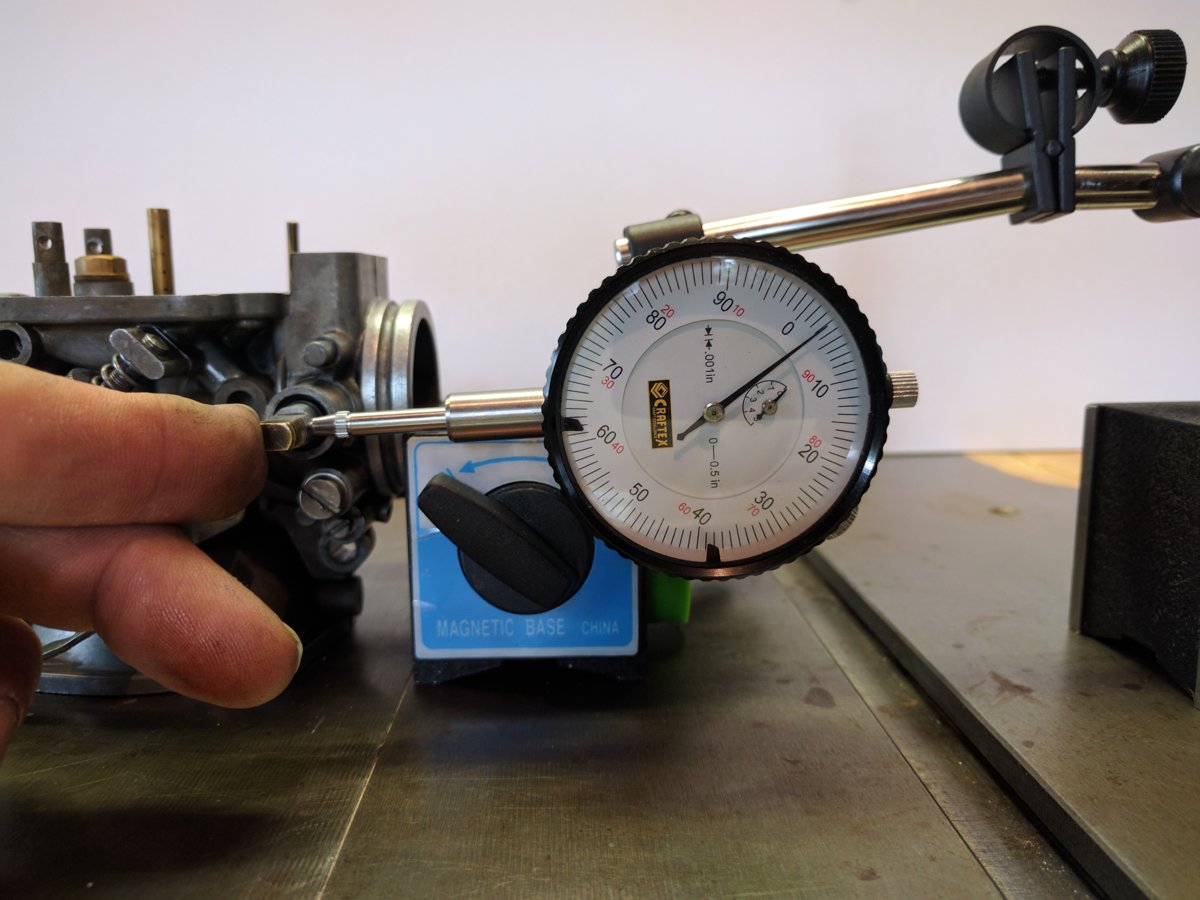

Decided to try and measure the amount of horizontal axial movement at the end of the throttle shaft. While my archaic measuring techniques aren't machinist accurate I was able to get really close to illustrate the amount of play that is there. I used a dial caliper in one magnetic base and a second magnetic base to clamp carb body to.

Right carb

Left carb

I'm not quite sure exactly what these reading indicate other than the fact that there is play horizontally across the end of the shaft axis from .003" to .005". Makes me wonder how much of this play there would be in a factory fresh set.

Now this all deals with the axial slop across shaft section but also got me wondering what is acceptable longitudinally.

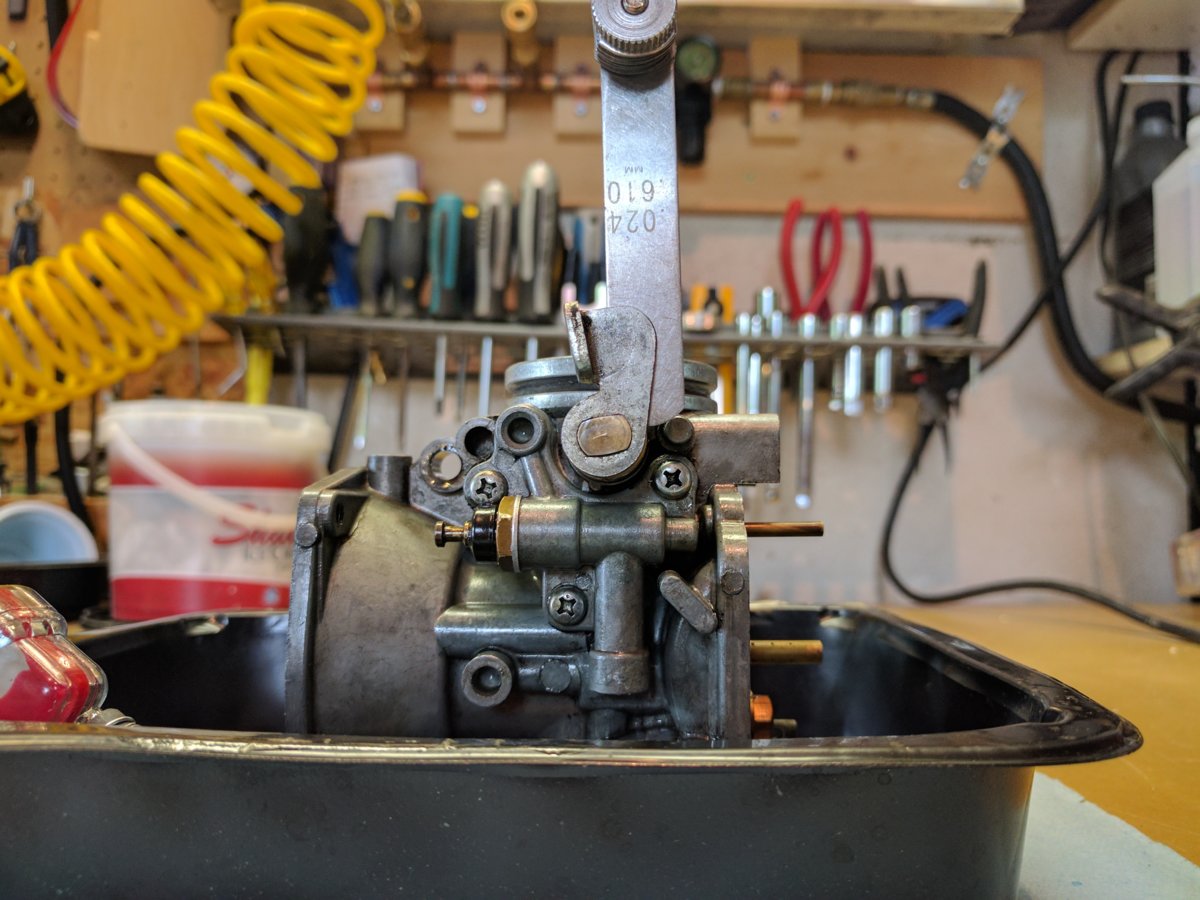

Here is an example of how I measured this:

I have longitudinal throttle shaft movement from.019" to .024" with butterflies fully open on three carb bodies.

If you happen by here again 2M, I have a few questions as you've been through this drill.

"You know, it breaks my heart to think of how many otherwise good carb bodies have been tossed just because of worn throttle bores. It would be great to be able to save them from the trash heap."

Since it looks like both of the 78/79 BS38’s that I have acquired suffer from this fate, (and what are the chances of that? I don't believe in those kind of coincidences), it sure leads me to wonder how many carbs are out there with guys just replacing throttle shaft seals and still wondering why they're not working right.

I have not reassembled and reinstalled carbs as of yet as I can't see how any assembly method with these existing conditions is going to matter. (Maybe I'm just being negative. You know I'm going to try it anyways)

Haven't got my carbs back from machinist yet, in spite of a few pop by's to order/pick up parts/give a little nudge visits so I can't verify the condition of my 74/75’s or the right carb on my first set of 78/79’s. Will do though when they're home again.

Thanks for any and all options and advice.

Guess I'll go clean up some more lectrics on my other project, BUT, would sure rather be riding on Canada's 150th birthday long weekend.

Ok, the question of the day is “how much slop is too much slop?”.

After reading through the above links kindly supplied by 2M, I decided to get some measurements similar to those done by him.

Can't insert an Excel spreadsheet so here is a screen capture:

2M in the first thread states:

My throttle shafts measure at 0.3145", and compared to that 0.3195", would allow for 0.005" of slop.

That was enough slop to allow the butterfly plate to catch on the throttle bore. I would say that slop values even less than that warrant a remedy...

So with mine being .0020" to .0040" I wonder how much less, and if these values are significant enough to allow seal air leaks and if they would indicate the need to replace bushings?

Decided to try and measure the amount of horizontal axial movement at the end of the throttle shaft. While my archaic measuring techniques aren't machinist accurate I was able to get really close to illustrate the amount of play that is there. I used a dial caliper in one magnetic base and a second magnetic base to clamp carb body to.

Right carb

Left carb

I'm not quite sure exactly what these reading indicate other than the fact that there is play horizontally across the end of the shaft axis from .003" to .005". Makes me wonder how much of this play there would be in a factory fresh set.

Now this all deals with the axial slop across shaft section but also got me wondering what is acceptable longitudinally.

Here is an example of how I measured this:

I have longitudinal throttle shaft movement from.019" to .024" with butterflies fully open on three carb bodies.

If you happen by here again 2M, I have a few questions as you've been through this drill.

- Is this much axial slop due to worn bushings going to allow the throttle shaft to shift too much therefore deforming throttle seals enough to leak air? Also causing butterflies to bind in bore resulting in a lean condition/ high idle issue? Solution - replace throttle shaft bushings?

- Would the longitudinal gaps and resultant slop over the shaft length also enhance the problem, especially with added cable pull force, allowing more air leakage? Therefore, would there be any point in adding shim washers on the inboard side of the staked throttle shaft washers / nylon bushings to reduce to longitudinal play? If so, what would be the 'right’ amount of gap? I realize there has to be enough clearance so as to not bind the throttle shaft, but what tolerances should we shoot for? Wouldn't it be nice to have the factory specs on this stuff?

- You obviously were able to successfully replace your bushings with new bronze and the 0.001” to 0.002” end shaft play you achieved is a huge improvement, however this comment by Xsbob in the second thread has me wondering.

“Those brass bushes you can see in the castings are actually cast in (usually they are splined to keep them from moving) and are then bored from a datum point on the casting. If you pull one out it is almost impossible to get the hole in line and concentric again as the cast in part is rarely concentric to the later drilled and reamed hole” How accurate did you find this statement to be? Didn't seem to cause a problem with your procedure though. - While not a question, I don't have any way to test throttle shaft trueness so who knows if and by how much this may be contributing to the overall problem.

"You know, it breaks my heart to think of how many otherwise good carb bodies have been tossed just because of worn throttle bores. It would be great to be able to save them from the trash heap."

Since it looks like both of the 78/79 BS38’s that I have acquired suffer from this fate, (and what are the chances of that? I don't believe in those kind of coincidences), it sure leads me to wonder how many carbs are out there with guys just replacing throttle shaft seals and still wondering why they're not working right.

I have not reassembled and reinstalled carbs as of yet as I can't see how any assembly method with these existing conditions is going to matter. (Maybe I'm just being negative. You know I'm going to try it anyways)

Haven't got my carbs back from machinist yet, in spite of a few pop by's to order/pick up parts/give a little nudge visits so I can't verify the condition of my 74/75’s or the right carb on my first set of 78/79’s. Will do though when they're home again.

Thanks for any and all options and advice.

Guess I'll go clean up some more lectrics on my other project, BUT, would sure rather be riding on Canada's 150th birthday long weekend.

Last edited:

Robin you are getting seriously detail oriented here. My hats off to you, you are straying into 2M territory here!

You know, obsession over minute details leads to becoming an expert. I am watching with great interest, even though I do not own precision measuring tools I would like to become more proficient with my carburetors.

You know, obsession over minute details leads to becoming an expert. I am watching with great interest, even though I do not own precision measuring tools I would like to become more proficient with my carburetors.

Thanks Bob, but I can't hold a candle to him.

Just trying to better understand the intricacies of these devices and provide details that he or others way more knowledgeable than me might be able to use to diagnose and suggest appropriate solutions.

If the values that I have measured indicate serious throttle shaft bushing wear that new seals won't patch and that can only be fixed with bushing replacement we might as well be aware of it and then explore solutions. As 2M has done by blazing a trail for us once again.

I wonder now as he did, how many others have this same problem after 40+ years.

It's fascinating really, and I am like a dog on a root. Not ready to give up yet.

Just trying to better understand the intricacies of these devices and provide details that he or others way more knowledgeable than me might be able to use to diagnose and suggest appropriate solutions.

If the values that I have measured indicate serious throttle shaft bushing wear that new seals won't patch and that can only be fixed with bushing replacement we might as well be aware of it and then explore solutions. As 2M has done by blazing a trail for us once again.

I wonder now as he did, how many others have this same problem after 40+ years.

It's fascinating really, and I am like a dog on a root. Not ready to give up yet.

Wow, excellent analysis and writeup, Rob.

Back when I reworked mine, I was prepared to do the ream and bush method. Then lucked out and found that mine were bushed. Don't know how that is on your *newfangled* carbs. Okay, addressing yer numbered list:

1- New OEM shaft seals have a generous flex range. I don't see any sealing problem with yours. My old seals didn't leak, even with the more generous shaft slop.

This situation is probably more serious on the early carbs, since they experience dual cable pulls, and reportedly have narrower shaft bores.

On your single cable, linked carbs, the cable forces are limited to the left carb only, producing wear there, as shown in your spreadsheet of slop values.

I'm thinking that OEM clearance values started in the 0.0015" - 0.0020" (40-50 micron) territory. Just a little extra slop would allow the shaft and butterfly to nudge upward during off-idle cable pull, possibly scrape/catch/bind at the upper throttle bore, AND shroud the transition ports up there, reducing the vacuum signal to them, AND admitting raw air at the bottom of the butterfly plate. This could cause an off-idle lean/stumble, and the pilots would need to be upped to compensate.

Also, if the throttle is blipped, the revs go up, throttle is dropped, intake vacuum skyrockets, putting upwards of 25 lbs force on the butterfly and shaft. If the throttle shaft bore is oblong, this may pull the butterfly upward into contact with the throttle bore, stopping its full closure. I had to offset the butterflys in my carbs to avoid this. Until the re-bush job.

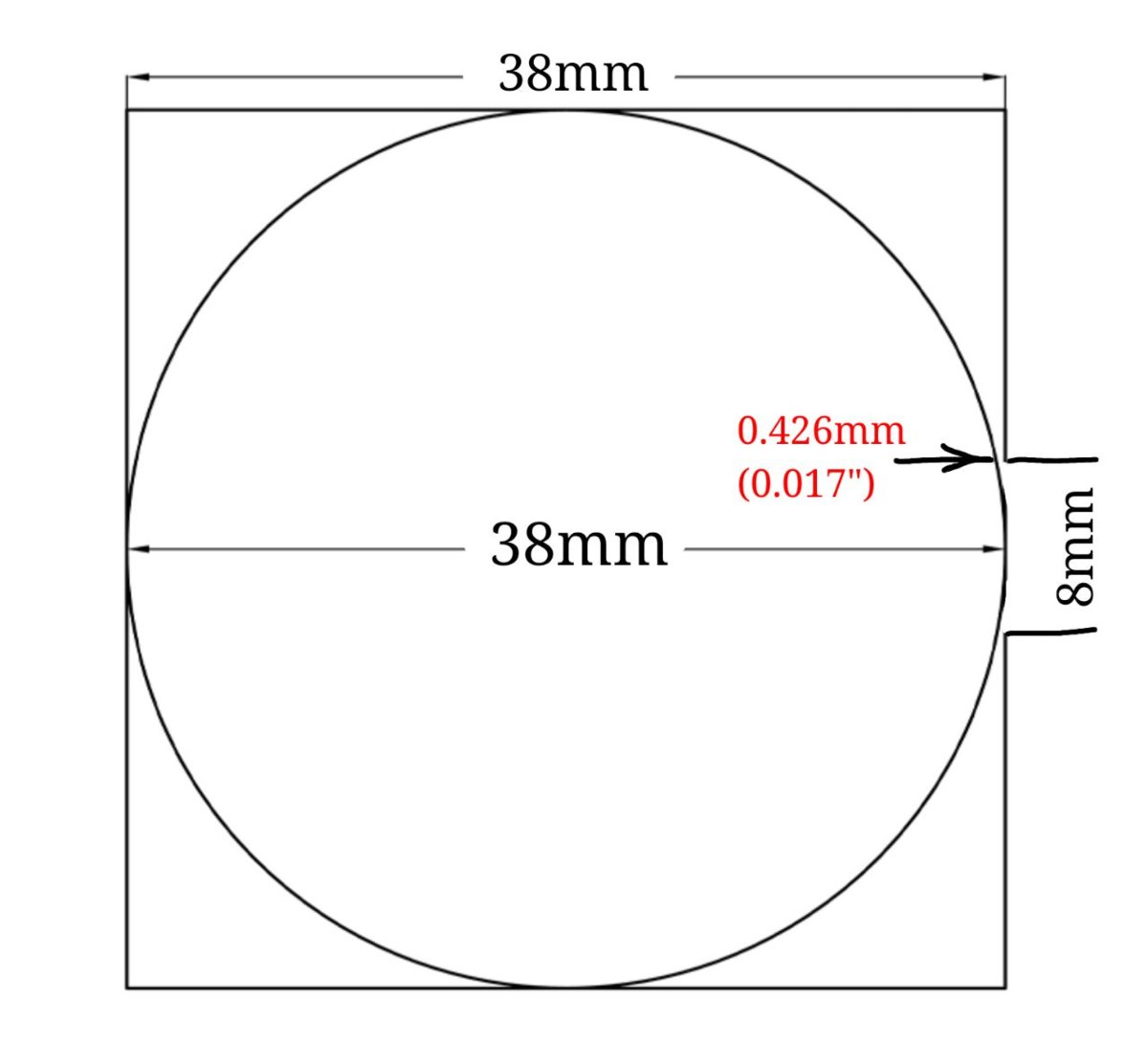

2- Longitudinal play. Having the throttle full open, butterfly flat and parallel with the bore, there will naturally be a large endplay. Visualize a 38mm disc, laying between 2 parallel lines, 38mm apart. Now, where the disc contacts those lines, draw the 8mm shaft bore. The disc edges no longer contact there.

Using trig, this edge clearance is like the chord of a circle. Radius 19mm, sin of 4mm (half the shaft dia), gives an angle of 12°. That's where the disc edge would contact the shaft bore. The cosine gives the clearance of 0.425mm (0.017"), which explains much of your longitudinal play. Guess I better include a drawing.

When properly setup, the shaft's endwasher should remain in full contact with the shaft bore edge, pulled there and held there by the outward force of the return spring. As such, there will be NO shaft longitudinal movement. It's at THAT shaft position where you want to center the butterfly in the bore. This way, the butterfly won't contact the throttle bore at the sides.

3- I lucked out with the replaceable bushings in my early carbs. Didn't expect to find those in there. Found a couple of other early carb pics that showed the bushings.

Never examined any later carbs, but so far everybody is reporting them as non-replaceable, cast-in (?) bronze (?). Otherwise, I haven't a clue what's in there.

4- The throttle shafts should pass cleanly into a long 8mm bore. Using a valve guide to test them is all I can think of at the moment. Maybe your machinist friend could turn a test piece for you? Or, simply chuck them up and straighten them?

EDIT: ROBINC - "Decided to try and measure the amount of horizontal axial movement at the end of the throttle shaft."

Excellent test method there, Rob. BUT, you want the VERTICAL axial movement, since that's the problematic wear direction that displaces the butterfly plate upwards towards the throttle bore...

Back when I reworked mine, I was prepared to do the ream and bush method. Then lucked out and found that mine were bushed. Don't know how that is on your *newfangled* carbs. Okay, addressing yer numbered list:

1- New OEM shaft seals have a generous flex range. I don't see any sealing problem with yours. My old seals didn't leak, even with the more generous shaft slop.

This situation is probably more serious on the early carbs, since they experience dual cable pulls, and reportedly have narrower shaft bores.

On your single cable, linked carbs, the cable forces are limited to the left carb only, producing wear there, as shown in your spreadsheet of slop values.

I'm thinking that OEM clearance values started in the 0.0015" - 0.0020" (40-50 micron) territory. Just a little extra slop would allow the shaft and butterfly to nudge upward during off-idle cable pull, possibly scrape/catch/bind at the upper throttle bore, AND shroud the transition ports up there, reducing the vacuum signal to them, AND admitting raw air at the bottom of the butterfly plate. This could cause an off-idle lean/stumble, and the pilots would need to be upped to compensate.

Also, if the throttle is blipped, the revs go up, throttle is dropped, intake vacuum skyrockets, putting upwards of 25 lbs force on the butterfly and shaft. If the throttle shaft bore is oblong, this may pull the butterfly upward into contact with the throttle bore, stopping its full closure. I had to offset the butterflys in my carbs to avoid this. Until the re-bush job.

2- Longitudinal play. Having the throttle full open, butterfly flat and parallel with the bore, there will naturally be a large endplay. Visualize a 38mm disc, laying between 2 parallel lines, 38mm apart. Now, where the disc contacts those lines, draw the 8mm shaft bore. The disc edges no longer contact there.

Using trig, this edge clearance is like the chord of a circle. Radius 19mm, sin of 4mm (half the shaft dia), gives an angle of 12°. That's where the disc edge would contact the shaft bore. The cosine gives the clearance of 0.425mm (0.017"), which explains much of your longitudinal play. Guess I better include a drawing.

When properly setup, the shaft's endwasher should remain in full contact with the shaft bore edge, pulled there and held there by the outward force of the return spring. As such, there will be NO shaft longitudinal movement. It's at THAT shaft position where you want to center the butterfly in the bore. This way, the butterfly won't contact the throttle bore at the sides.

3- I lucked out with the replaceable bushings in my early carbs. Didn't expect to find those in there. Found a couple of other early carb pics that showed the bushings.

Never examined any later carbs, but so far everybody is reporting them as non-replaceable, cast-in (?) bronze (?). Otherwise, I haven't a clue what's in there.

4- The throttle shafts should pass cleanly into a long 8mm bore. Using a valve guide to test them is all I can think of at the moment. Maybe your machinist friend could turn a test piece for you? Or, simply chuck them up and straighten them?

EDIT: ROBINC - "Decided to try and measure the amount of horizontal axial movement at the end of the throttle shaft."

Excellent test method there, Rob. BUT, you want the VERTICAL axial movement, since that's the problematic wear direction that displaces the butterfly plate upwards towards the throttle bore...

Last edited:

Thank you 2M, you are inspiring me to try and dig a little deeper on this. Your reply gives me some more to chew on.

Re: 1. Isn't it interesting then how with new OEM shaft seals installed, after a warm up run, the right carb outboard bore leaked.

Idle was fluctuating when I came to a stop, and when tested with WD40 idle would increase. I didn't have the throttle shaft pushed inwards as you suggest when I tightened butterflies into place, but I would think this would only affect butterfly function and not seal function.

I'm thinking (dangerous) the staked washers only job is to hold the throttle shaft in place, not the seal, as the seal does not sit proud of it's bore but rather is inset, and would be pulled into the bottom of the bore by carb vacuum?

Solution, runs great at mid and upper carb ranges so don't slow down or stop.

Re: 2. If I pushed inward on the right carb staked shaft washer, idle would also increase. I don't know if this would happen on any carb set as this additional horizontal force is unnatural. It just dawned on me that this idle increase may have nothing to do with the seal, but rather is forcing the butterfly to climb the inside throttle bore wall thus increasing idle?

The left side of the throttle shafts are machined flat for the special washer and throttle linkages. This stepped/machined portion extends outwards of the throttle shaft bore so it can only be tightened so much. I'm guessing so they can't be over tightened therefore locking up butterflies.

(I will insert a pic a little later.)

So would it be fair to assume the seals have to do their job with vacuum and no mechanical assistance?

Re: 3. Bushings are bronze or brass? I will look to see if I can see evidence of them being splined and cast in place.

If these are not replaceable, that sucks.

Re:4. Throttle shafts are turning freely but being out by .005" as yours were, wouldn't be noticeable by my turning of the shaft but would be by normal carb cable operation.

Hate to add anything else to his job list....lol.

I will explore further and update a little later. Have to go to a meeting (on a long weekend Saturday morning, the joys of self employment)

New OEM shaft seals have a generous flex range. I don't see any sealing problem with yours.

Re: 1. Isn't it interesting then how with new OEM shaft seals installed, after a warm up run, the right carb outboard bore leaked.

Idle was fluctuating when I came to a stop, and when tested with WD40 idle would increase. I didn't have the throttle shaft pushed inwards as you suggest when I tightened butterflies into place, but I would think this would only affect butterfly function and not seal function.

I'm thinking (dangerous) the staked washers only job is to hold the throttle shaft in place, not the seal, as the seal does not sit proud of it's bore but rather is inset, and would be pulled into the bottom of the bore by carb vacuum?

Solution, runs great at mid and upper carb ranges so don't slow down or stop.

Re: 2. If I pushed inward on the right carb staked shaft washer, idle would also increase. I don't know if this would happen on any carb set as this additional horizontal force is unnatural. It just dawned on me that this idle increase may have nothing to do with the seal, but rather is forcing the butterfly to climb the inside throttle bore wall thus increasing idle?

The left side of the throttle shafts are machined flat for the special washer and throttle linkages. This stepped/machined portion extends outwards of the throttle shaft bore so it can only be tightened so much. I'm guessing so they can't be over tightened therefore locking up butterflies.

(I will insert a pic a little later.)

So would it be fair to assume the seals have to do their job with vacuum and no mechanical assistance?

Re: 3. Bushings are bronze or brass? I will look to see if I can see evidence of them being splined and cast in place.

If these are not replaceable, that sucks.

Re:4. Throttle shafts are turning freely but being out by .005" as yours were, wouldn't be noticeable by my turning of the shaft but would be by normal carb cable operation.

Hate to add anything else to his job list....lol.

I will explore further and update a little later. Have to go to a meeting (on a long weekend Saturday morning, the joys of self employment)

Part of the throttle shaft sealing is from the close fit of shaft to bore. Enuff slop in there and the seals will see the potential for greater leakage.

I used silicone grease on reassembly. In the throttle shaft bores, and fully packed around the seals. It helps with the sealing. If the fit is close and there's no leakage, then that grease should stay in there. And, gasoline shouldn't be able to wick in there. Well, that's the thinking anyway.

Use a backlight while centering the butterflys in the bores. Watch for cocked light leakage, indicating a need to slightly rotate the plate. You want plate contact at the top and bottom only, as shown in one of my album pics. The "snap close" method won't rotate a cocked plate. The 2 holes in the butterfly plates are oversized, allowing for these adjustments, but there's always Murphy's laws. Ensure that plate adjustments aren't hindered by misplaced holes. May need some fine file work if so.

Edit: Did you confirm that your 38mm throttle bores are indeed perfect circles, no oblong?

Edit2: Re your #2. Your thinking is correct. If the shaft hasn't been properly set, restricted by the endwasher, wierdness happens...

I used silicone grease on reassembly. In the throttle shaft bores, and fully packed around the seals. It helps with the sealing. If the fit is close and there's no leakage, then that grease should stay in there. And, gasoline shouldn't be able to wick in there. Well, that's the thinking anyway.

Use a backlight while centering the butterflys in the bores. Watch for cocked light leakage, indicating a need to slightly rotate the plate. You want plate contact at the top and bottom only, as shown in one of my album pics. The "snap close" method won't rotate a cocked plate. The 2 holes in the butterfly plates are oversized, allowing for these adjustments, but there's always Murphy's laws. Ensure that plate adjustments aren't hindered by misplaced holes. May need some fine file work if so.

Edit: Did you confirm that your 38mm throttle bores are indeed perfect circles, no oblong?

Edit2: Re your #2. Your thinking is correct. If the shaft hasn't been properly set, restricted by the endwasher, wierdness happens...

Last edited:

Just caught this as I'm heading out. Thanks 2M.

Quick question. I have not had any luck finding Sil-Glyde north of the 49th. Will check if Napa is open on our holiday weekend.

What would be acceptable alternatives?

Dielectric grease? Vaseline?

Quick question. I have not had any luck finding Sil-Glyde north of the 49th. Will check if Napa is open on our holiday weekend.

What would be acceptable alternatives?

Dielectric grease? Vaseline?

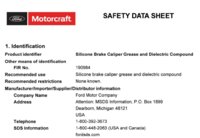

Yes, there's better stuff than Sil-glyde, which is about 70% castor oil. Don't use petroleum based Vaseline.

The battery post dielectric greases are supposed to be 100% silicone based.

I'm still researching this silicone grease stuff. Tough as nails to figure out their secret/proprietary formulations. Castor oil, glycols, other additives, can be found in a lot of offerings, each with their own advantages and disadvantages. An incomplete project, these are what I've found so far that are supposed to be 100% silicone based:

The battery post dielectric greases are supposed to be 100% silicone based.

I'm still researching this silicone grease stuff. Tough as nails to figure out their secret/proprietary formulations. Castor oil, glycols, other additives, can be found in a lot of offerings, each with their own advantages and disadvantages. An incomplete project, these are what I've found so far that are supposed to be 100% silicone based:

Similar threads

- Replies

- 15

- Views

- 2K