neanderthal

neanderthal

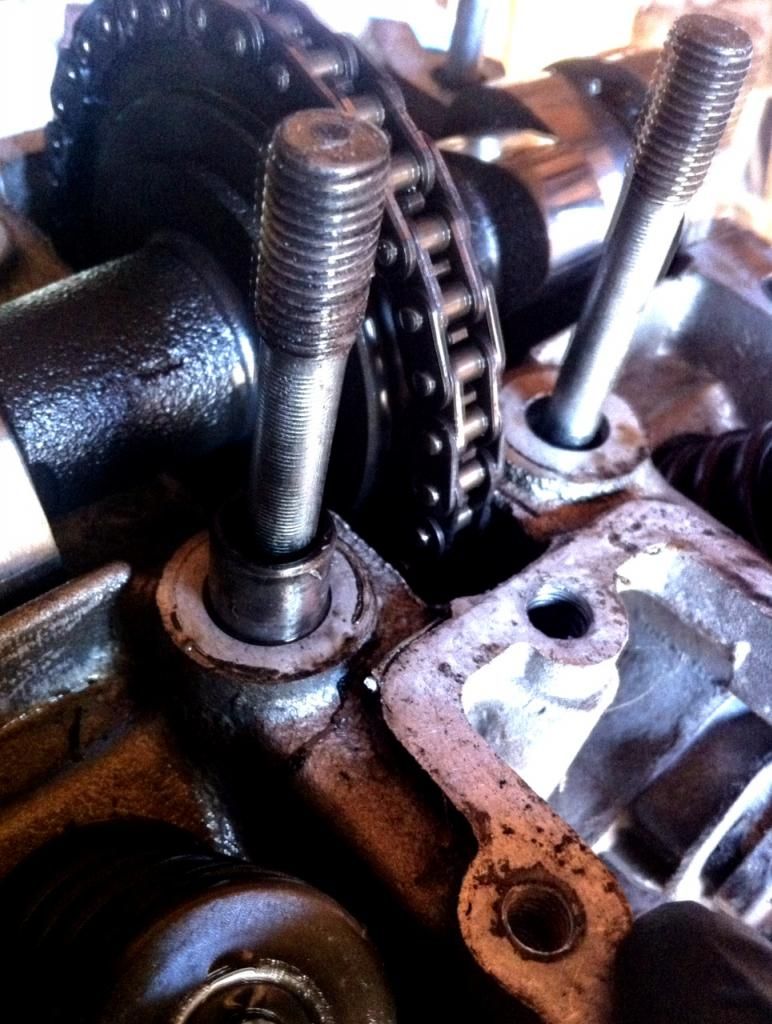

So ill start out saying this is a build that i started a few months ago when i jut moved up to portland. its going to be a long and slow build, but hoping to have it finished before spring time. i love the bobber look so im headed in that direction, this is my first real build, ive done a few others but nothing like this and in depth. Ill also be attempting my first engine rebuild as well...we'll see how that goes. After a month or so of living up here i sold a few xs' to a guy up here who has a metal working shop. He is kind enough to let me use it for a while and show me some really cool techniques. So my build has stepped up a few notches from what i was originally going to do. very excited about that.

also open to any and all thoughts good or bad. and anything you think would look good for this build is a plus! share your ideas and thoughts please!

i started off buying a pile of parts off a guy in portland who is also on this forum. I only wanted an engine and frame out of him, but ended up buying it all and selling the rest. well most off it go sold off...i also go super lucky and bought a second pile of bikes, 3 complete bikes and a bunch of parts including two minuki round slid carbs which ill need help identifying later when i get to that. all that was for 1000. that pile has really help fund this project.

i wasnt too thrilled about the front of the frame, it looked to sharp or square, im going to attempt a leaf springer front end and wanted it to flow better so i messed with it a bit.

first time doing anything like this. it took me three times to get it right. good practice for the leafer

think i need to do something with the gusset. doesnt flow to well.

For wheels im running a stock harley iron head rear and a 21 laced to a harley hub.

i had to turn down an axel for the rear. i think that i may not like the 21 sense its 3.25 inches wide. I want vintage looking wheels and i want them to look as close to in size as possible. any help would be great. i want a big fatty on the back and hoping to find a lower profile tire for the front to even it out. i may just start over on the front if it doesnt work out i hope it does.

i hope it does.

before and after watching two hours of you tube videos and reading on this forum. lost of help came out better that i thought. first time polishing as well...not the best, but im happy with the results.

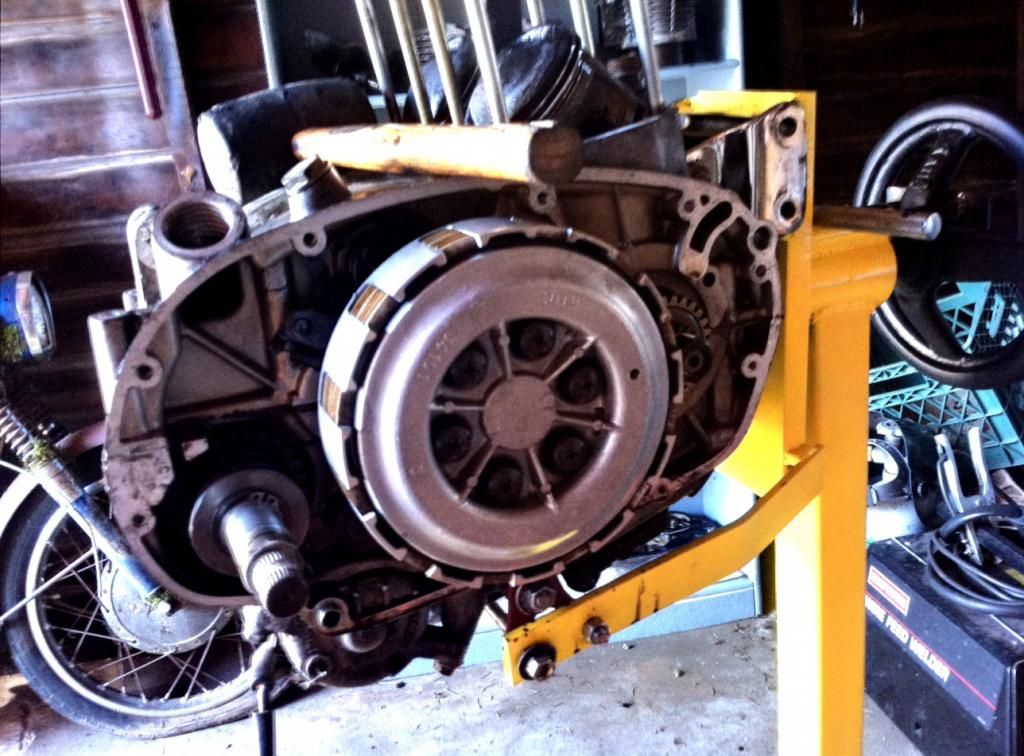

So now i need to figure out what meats i want for the rims so i can figure out the rest. I also should receive my uppers and lowers that im getting laser cut out for the leafer forks. i want to build the leafer first. my front end will be a deciding factor on my rear fender and tank, which will also affect my seat option and so on. so now im working on the first of hopefully many engine rebuilds. i have little time welding so i thought id practice on a engine stand, this would also help me get comfortable with all my new found toys at hand!

help keep it greased up and moving..its still a heavy engine and a small wheel. haha it was a good thought.

welding around things is tough, but im learning...its really easy to make these look ugly.

and here it is finished.

also open to any and all thoughts good or bad. and anything you think would look good for this build is a plus! share your ideas and thoughts please!

i started off buying a pile of parts off a guy in portland who is also on this forum. I only wanted an engine and frame out of him, but ended up buying it all and selling the rest. well most off it go sold off...i also go super lucky and bought a second pile of bikes, 3 complete bikes and a bunch of parts including two minuki round slid carbs which ill need help identifying later when i get to that. all that was for 1000. that pile has really help fund this project.

i wasnt too thrilled about the front of the frame, it looked to sharp or square, im going to attempt a leaf springer front end and wanted it to flow better so i messed with it a bit.

first time doing anything like this. it took me three times to get it right. good practice for the leafer

think i need to do something with the gusset. doesnt flow to well.

For wheels im running a stock harley iron head rear and a 21 laced to a harley hub.

i had to turn down an axel for the rear. i think that i may not like the 21 sense its 3.25 inches wide. I want vintage looking wheels and i want them to look as close to in size as possible. any help would be great. i want a big fatty on the back and hoping to find a lower profile tire for the front to even it out. i may just start over on the front if it doesnt work out

i hope it does.

i hope it does.before and after watching two hours of you tube videos and reading on this forum. lost of help came out better that i thought. first time polishing as well...not the best, but im happy with the results.

So now i need to figure out what meats i want for the rims so i can figure out the rest. I also should receive my uppers and lowers that im getting laser cut out for the leafer forks. i want to build the leafer first. my front end will be a deciding factor on my rear fender and tank, which will also affect my seat option and so on. so now im working on the first of hopefully many engine rebuilds. i have little time welding so i thought id practice on a engine stand, this would also help me get comfortable with all my new found toys at hand!

help keep it greased up and moving..its still a heavy engine and a small wheel. haha it was a good thought.

welding around things is tough, but im learning...its really easy to make these look ugly.

and here it is finished.