In the past I've done it with it off but may try with it on next time. Off, it's easy to "pinch" in the vice, but you lose some of that while spreading it to re-install. It's best to snap it back on over the top. If you stick it on from the side, it really gets spread apart.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Power to the Coil

- Thread starter Paul75

- Start date

Agreed - I pinched mine with the clip off the gear and then slipped it on over the end into the little groove.

The idea is to NOT open it any more than necessary when re-installing it.

Pete

The idea is to NOT open it any more than necessary when re-installing it.

Pete

Guys, so I completed this but the clutch is not engaging. I read through other posts regarding this and decided to drop the oil again and take a closer look at the clutch and lightly rub the clutch basket with 1000 grit wet and dry to make sure the plates run smoothly, so all good there.

I've reassembled and put oil back in but it's still not engaging.....any ideas?

I've reassembled and put oil back in but it's still not engaging.....any ideas?

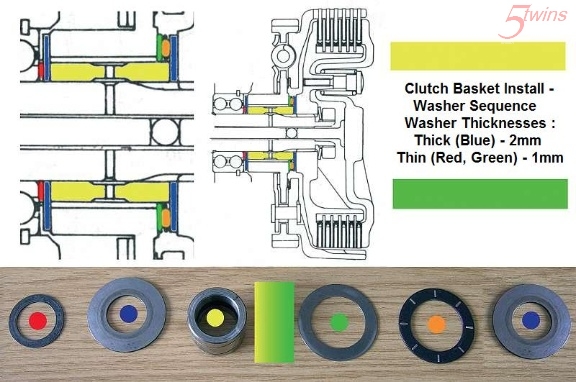

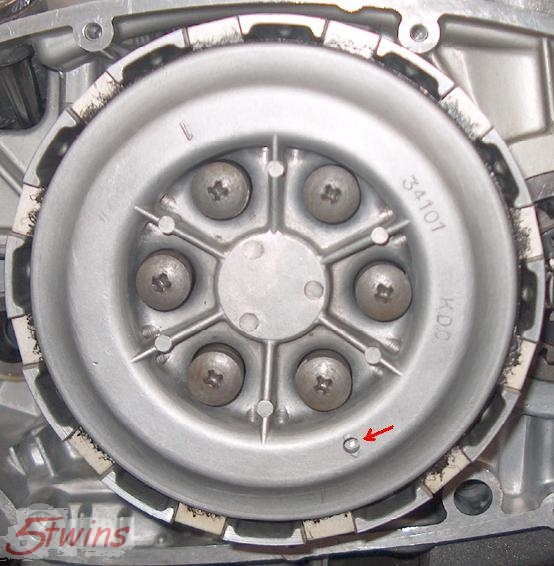

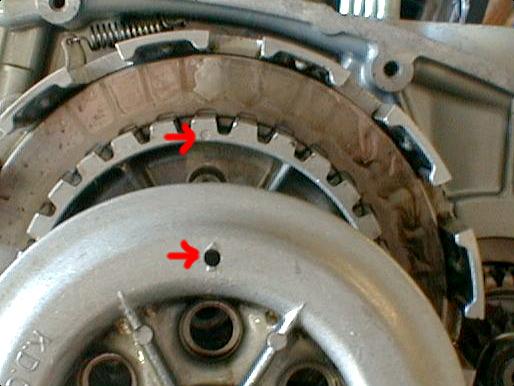

Well, you have to be sure you got the spacer washer sequence correct on the clutch hub, also the correct pressure plate alignment. There's a dot stamped on one of the inner hub's teeth and it must show through a little hole in the pressure plate for alignment to be correct .....

Also, it seems any time you have the clutch all apart, a re-adjustment at the worm gear is needed, don't know why.

Also, it seems any time you have the clutch all apart, a re-adjustment at the worm gear is needed, don't know why.

Did you index the clutch?

Look at my 2nd pic above. The lock tab needs to be directly under the nut. If the black washer is between it and the nut, it won't fold up tight against the side of the nut and lock it down properly. But, mixing this up shouldn't have any effect on hub spacing or clutch function, just on keeping the nut tight.

I agree with you 5T, this is the logical way however if the washer goes on first then the lock tab doesn't sit flush as it's up against the washer, frustratingly there are also a couple of youtube videos which don't show it like this........if I do take the clutch out again I'll alter it your way.....

The lock tabs on the lock washer are long enough to reach over the black washer and fit into the clutch hub. In fact, if you put the lock washer on 1st, the tabs are too long and bottom out on the hub before the the rest of the washer hits. The parts diagram also shows it directly beneath the nut.

Still struggling with this clutch, just adjusted the worm gear screw and nut. The bike is on the centre stand and in 1st. When I pull in the clutch the rear wheel is still in gear and not moving freely, is this normal as I've read it can be hard to spin the wheel.....or should it rotate freely?

I guess the only true test will be once it's running. Plunk it in 1st and hope it doesn't lurch forward and stall the bike. If you've read through some of the clutch threads then you know it isn't the greatest on this bike. Sure, it works, but it has lots of drag and that can make for stiff shifting and hard to find neutral when hot. The problem is barely adequate plate separation and that gets worse as the bike heats up and parts expand. That's why most of us adjust the clutch quite snug cold. That way when it gets hot and parts are expanded, it still continues to work acceptably. You won't find neutral as easily as when it's stone cold, but you can live with it.

And speaking of the stiff shifting, something you'll want to routinely check is the tightness of the shift lever. It gets loose on the shaft splines quite a lot and will require tightening. Sometimes you can't get it tight enough. The 2 halves of the split in the side will touch before it's tight on the splines. That will require a little filing of the slot to make it a bit bigger. You don't want to run it loose, that can eventually strip the splines.

And speaking of the stiff shifting, something you'll want to routinely check is the tightness of the shift lever. It gets loose on the shaft splines quite a lot and will require tightening. Sometimes you can't get it tight enough. The 2 halves of the split in the side will touch before it's tight on the splines. That will require a little filing of the slot to make it a bit bigger. You don't want to run it loose, that can eventually strip the splines.