That 50 hp. claim was gross hp.--measured at the crank with no alternator or drive gear dragging down the numbers. Net (wheel) hp. is lower, usually low to mid 40's on a stock motor. Regarding makers' advertised power back in the day, our thinking was that the Japanese raised pretty small horses....

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Messages

- 683

- Reaction score

- 1,477

- Points

- 143

Good one!small horses....

Good one!

In one period road test (around 1980), a 70 hp Ducati 900SS kept up with a Honds CB900F (95 japanese hp) in acelleration and top speed.

Where did those extra 25 ponies disappear?

Hudriwudri

XS650 Addict

To revive an old thread, and to drop my 2cents into the discussions.

Personally I'm convinced (have built a couple +50 street engines) that 60ish HP are possibly on no holds barred Sr/tt/XT engines.

Although one has to admit that at that level it turns more into open heart surgery

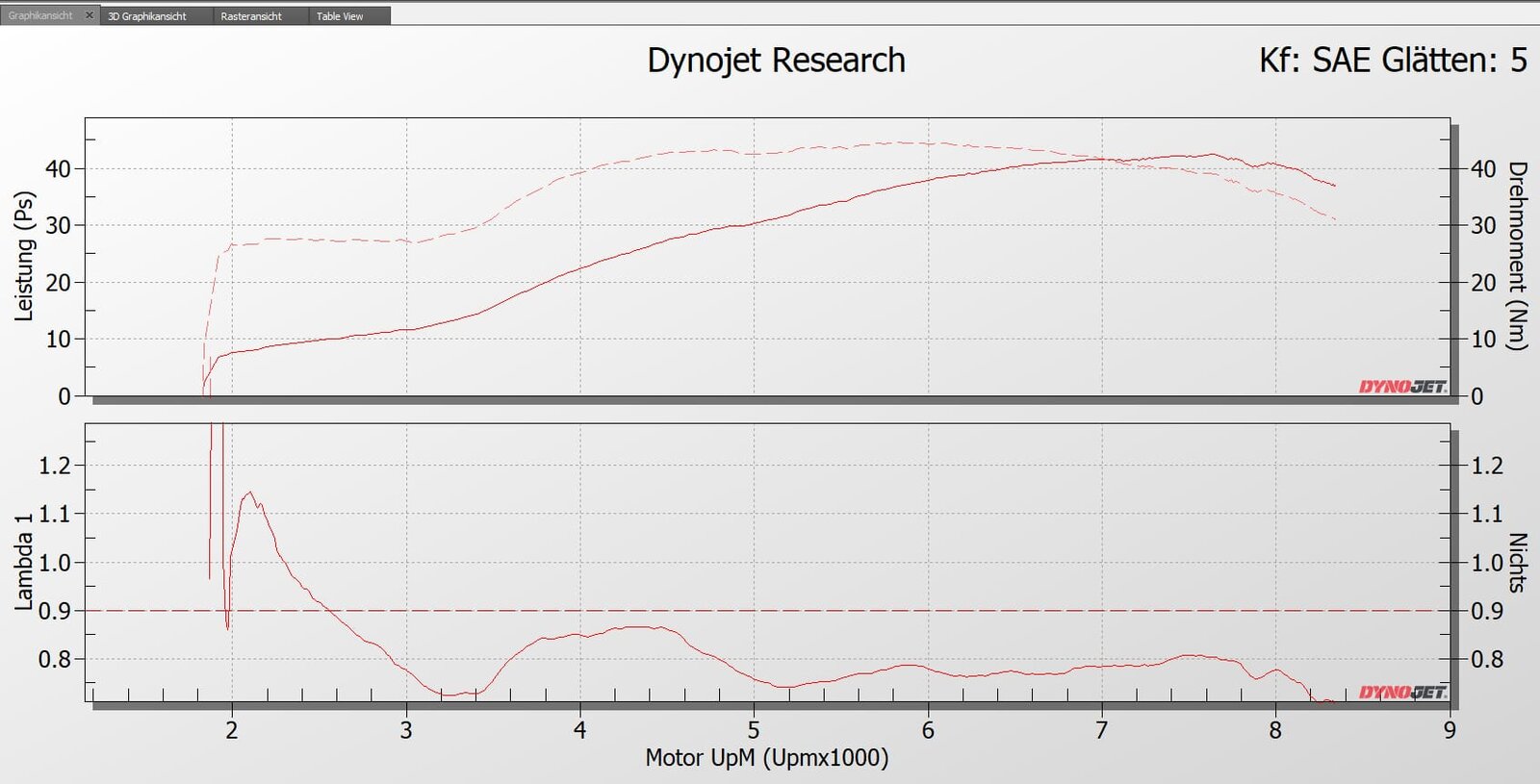

Attached pic is of a street Sr engine for which i did a while back the top end work with 89mm piston and other assorted parts somewhat of the shelf.

Given the fact that this engine has still 89mm and is not a 93/95 short stroke motor (with matching cam and valve sizes, etc) there is in my experience still plenty of room (also with some effort in the port walls of the bowl area and adjoining area) to get more substantial numbers out of the old mill.

Accordingly i would assume that a nicely done xs880 should also be able to scratch on the +70~80 HP level with matching cam, big valves, combustion chamber work and correct suiting porting, etc.

Kind greetings Christian

Personally I'm convinced (have built a couple +50 street engines) that 60ish HP are possibly on no holds barred Sr/tt/XT engines.

Although one has to admit that at that level it turns more into open heart surgery

Attached pic is of a street Sr engine for which i did a while back the top end work with 89mm piston and other assorted parts somewhat of the shelf.

Given the fact that this engine has still 89mm and is not a 93/95 short stroke motor (with matching cam and valve sizes, etc) there is in my experience still plenty of room (also with some effort in the port walls of the bowl area and adjoining area) to get more substantial numbers out of the old mill.

Accordingly i would assume that a nicely done xs880 should also be able to scratch on the +70~80 HP level with matching cam, big valves, combustion chamber work and correct suiting porting, etc.

Kind greetings Christian

Oldnwiser

XS650 Enthusiast

The port size is adequate but the shape causes backups from velocity eddies and slow sluggish speeds. On the intakes raise the roof gradually and open the bowls but don’t do anything to the floor after the turn. I use a bowl hog the size of the valves then keep the floor narrow and widen the top all the way to the manifold (intake) and if you can try to keep that shape in the manifold and if you are running a magneto or deleting the electric start, block it off get a battery that will allow you to attach 2-3 more inches of manifold the same shape, btw I used Virago intake valves, then attach the boots and carbs with pods. The exhaust just wants out and they are plenty big. The intake with that spread \_/ shape with the roof Wider than the floor and a double length manifold the same shape is worth torque and without swirl and backups hp. I wish I could draw it out, but David Vizard can help you get the most out of the head.,at 45 ci, 70 hp and 65 ft lbs is not out of reason with the long intake ports and good exhaust. And a 300 degree rephased cam similar to the XS2 specs. I port my wedge heads the same way.I never really do a full on port job with these heads,but if you smooth out the exhaust ports casting flaws and take some of the valve guide boss area down and then just take out the casting flaws on the intake side,you"ll notice a difference.You dont want to take too much off because the exhaust and intake ports are almost too big as it is for the size of the valve.

Oldnwiser

XS650 Enthusiast

Lengthening any way you can on the intake ports and manifolds will improve your performance in daily use. Long intake ports will pick up torque and my post on hogging the intake bowl and keeping the floor after the turn narrow and widening the roof of the intake port and manifold will surprise you with how much useful power you gain 3000-6000 and still rev out. Longer ports will amplify the flow in the low to mid range and all the way out. You only have atmospheric pressure on the intake side, so the more mixture you can have ready when the valve pops barely open will be almost like what a supercharger does just by the amount of mix there. Exhaust just wants out and during overlap you are in that period pulling the air at higher than atmospheric pressure for that short time.Hi Gary,

I believe what Michael is trying to achieve with the anti reversion cones and reducing the diameter of 1 3/4" exhaust is engine smoothness/driveability at lower rpm.

Tom

Oldnwiser

XS650 Enthusiast

Exactly! Those from my magnifier appear to be Delortos, I can’t read any text on them, are they pumpers with the atomizer accelerator pump? I do like that manifold, that’s like a tunnel ram! I bet it would about pull a house with that induction. Did yo make it or scavenge pieces from another bike? How much did it knock off of the top end?Do you think these are long enough View attachment 232196

Oldnwiser

XS650 Enthusiast

On V8s I have built Ford FE s mainly that is exactly how I have my pistons, a good dome, light balanced skirts and with floating pins as light of pins as will live as a fulcrum for the reciprocal mass kept in place by springs or Spirolox. I have a 500 hp 390 that I built in 1999 weighing everything, and matching it all up, and none of it was exotic expensive material. Just carefully machined and matched, I drag raced it for a few years, daily driver a few years, and my son can take the car out to get everything “wet” and 7000 rpm’s seems to do it and that strategy is pretty well descriptive of how to build a long life engine without going broke. I really hope that future generations can absorb this as it way more important than the parts that are thrown into the battle. I have also used 352/360 rods and tool steel pins with Spirolox because they improve the rod ratio and allow the pin to be higher in the piston and with this reduced force to the crank pins you maintain a better wedge of oil and a more stable environment that reduces friction and temperature variations.And by reducing upper reciprocating mass will also reduce engine vibs. Forged pistons are heavier cause of the mass under the dome. You only need .160 to .200 dome thickness to prevent melting through the dome. Forged piston mass will also vary depending on forge material and overall piston design. 650centrals long rod piston is a fine example of this and that piston could have have been further lighten. The forged pistons I have in my BMW where 10% lighter than stock and I further lightened the pistons by installing TOOL STEEL wrist pins that shaved off 20 grams of mass.

Last edited:

Oldnwiser , they are tapered 36mm to 34mm so there's no step, with the taper at the head end so they can be shortened, made in local machine shop for me.

I have lost no top end, in fact putting them on I gained 5mph on terminal speed,

I have lost no top end, in fact putting them on I gained 5mph on terminal speed,

Oldnwiser

XS650 Enthusiast

My XS heads took some work but shape is still a big game changer when it comes to flow, especially with a hemispherical shaped chamber. You can’t use wedge principles with a SOHC Hemi. I learned that from working with Ford aftermarket design to possibly reassurect the 427 SOHC to complete in AA/S with the Chrysler Hemi. Ford Engineers had painted themselves into the same corner the XS 650 head was. The SOHC with 1:1-1.2:1 buckets and followers put a choke chain on ratio. The cams had to grow and we know that the Single valves on each side required lobes that ran air speed either too fast or too slow. I managed by porting a head from a Heritage Special 447. I reshaped the ports on both sides to flow a balanced 242intake and 200 cfm exhaust. But the trick was to create a trapezoidal port on the intake side so that this peak plow occurred at .300, the exhaust at .250 by reducing the size so that during overlap the exhaust would blast out and using the right cam, the XS2 specs with generous overlap would pull much more airspeed to get the air flowing. The engine made good torque and hp a real overachiever, and the 427 SOHC when scaled up was a really strong. Surprisingly though a pushrod Hemi with 1.8 ratios had its number. The project was dropped in favor of the 7.3 Godzilla as the future, just GM saw the same writing with LS and Mopar…. So a 750 SOHC will always be a 70 hp 70 lbs ft engine and that is more than than most people need on the road. 4 valve, you get more but not proportionally. 2 more cylinders with the 4 valve head, but it loses that 2 cylinder 270/90 277/83 or 360 degree charm. A 750 air cooled SOHC at 70/70 on a nice lithe frame is pretty darn sweet, and if I could see to ride and build it, be on it like a chicken on a junebug. How’s about you guys? It’s 1.53 per cubic inch on pump gas built as an air cooled engine and 1.53 ft lbs per cube. That will sound as wicked as any Harley, make more power on a cafe racer than even a Vincent Black Lightning and you won’t have to lay flat in your skivvies on the salt to break the records that Vincent set. On an XS2 style cafe profiled racer, what in the world would anyone need, maybe the long intake DelOrto setup could get you to 77/85 hp and tq? Man I want that intake ? Lol. That would be 1.68/1.81, are you talking orders for these intakes? Man a 45.7 ci 1.7 hp per ci and 1.81 ft lb per cube, har har har! CB750 with a little Kaw MK 4 thrown in?Hey Jack,

Good seeing you still around.

We're pushing 133cfm/sq-in through the MCSA of the head. Peak flow is 235cfm @ 28" @ .600" lift (230cfm @ .500) through the spigot.

With the carburetor and velocity stack bolted on, it goes down to 216.3cfm @ .600 and 208cfm @ .500

A TM-38 will flow 277cfm @ 28" H20 at full open, or 156cfm/sq-in.

This is by all means, not a 'maximum effort' deal. Looking to peak around 7000rpm on a 540cc deal on the street engine. A 40-42mm dia "MCSA" will allow the head to reach a bit over 240cfm.

The two biggest limitations with the stock Yamaha castings are:

1) material in the port sidewalls. This limits how far you can widen the short side radius. We're about at the limit of what we can do.

You can see here:

MCSA is at the port entrance to the head - it needs to be back that far as the port needs to gain area from there to slow down the air enough to get it around the short side radius without separation.

2) Valve lift. Being an OHC set-up, you're ultimately limited on how much valve lift you can run. On a pushrod set up, you can juts keep putting longer valve stems in and work with a rocker manufacturer and come up with a higher rocker ratio than stock. The Royal Enfield guys have done exactly this and are seeing over .600" valve lift without Myhaving to use more lobe lift. A win-win.

We're great on velocity - averaging about 300fps through the port. Believe it or not a bigger valve for us did not gain much in cfm, but did make the port more stable and quiet with work. A great thing since running depression can be over 3x what you can measure on the bench.

Last edited:

Hudriwudri

XS650 Addict

@Oldnwiser

242cfm/0.30" intake and 200cfm/0.25" exhaust sounds kind of a lot.

Could you let us know at which test pressure which would shed some light to those numbers?

Thanks for the info.

Kind regards christian

Ps: yes those dellortos are pumpers as the pump is sitting behind the tower, while both of them seem to be somewhat of an older serious as they are spigot mounted and not rubber mounted with aluminum carburetor tops.

242cfm/0.30" intake and 200cfm/0.25" exhaust sounds kind of a lot.

Could you let us know at which test pressure which would shed some light to those numbers?

Thanks for the info.

Kind regards christian

Ps: yes those dellortos are pumpers as the pump is sitting behind the tower, while both of them seem to be somewhat of an older serious as they are spigot mounted and not rubber mounted with aluminum carburetor tops.

Last edited:

Oldnwiser

XS650 Enthusiast

I want to make a long Y as a 2-1 with a single pumper Lectron or the Edelbrock version but the best is a Delorto. I would like to do a real 270/90 with the XS2 cam and a 2-1 with a big plenum and a cone filter amplifier like you have, but just a single carb straight back. Does the Delorto have a power ( intermediate) circuit and accelerator pump on that model? Or hey? The plenum and a Holley 500 2V Lol.

Oldnwiser

XS650 Enthusiast

I d think it would have to have the alt rotor for balance. And the trans may need the sprocket?That 50 hp. claim was gross hp.--measured at the crank with no alternator or drive gear dragging down the numbers. Net (wheel) hp. is lower, usually low to mid 40's on a stock motor. Regarding makers' advertised power back in the day, our thinking was that the Japanese raised pretty small horses....

Oldnwiser

XS650 Enthusiast

I can’t stop looking at that beautiful pair…. Is the video an 880 rephrase 270/90 with a 533 crank? It has a really good snort!Had some made for 38mm dellortos for next year

A video from earlier this year.View attachment 232354

Hudriwudri

XS650 Addict

Dell'orto has immediate pumping action by means of ramps on the carburetor slide (quite different from mikunis or keihins) so one has to buy or modify a slide accordingly and adjust the lift on the pump. Usually not needed if correct atomizer tube/mixture jet is chosen.

Lectrons never came with accelerator pumps.

Could you let us know the test pressure to achieve your stated flow numbers?

I maybe did not fully understand the flow number story, are you saying those numbers were achieved on a Ford SOHC or did you want to say they were achieved on a xs head?

Thanks for shedding light.

Kind regards christian

Lectrons never came with accelerator pumps.

Could you let us know the test pressure to achieve your stated flow numbers?

I maybe did not fully understand the flow number story, are you saying those numbers were achieved on a Ford SOHC or did you want to say they were achieved on a xs head?

Thanks for shedding light.

Kind regards christian

Last edited:

I can’t stop looking at that beautiful pair…. Is the video an 880 rephrase 270/90 with a 533 crank? It has a really good snort!

360 degree crank, 750cc JE pistons, 477 crank, unknown cam not high lift but long duration with the exhaust longer than the inlet, bit of work on the head, with 1mm over valves

Does 0-92 in 7.469 seconds which is 1/8th mile

Attachments

Oldnwiser

XS650 Enthusiast

The test was done at 28 hg like an automobile head. The port shape is very easy to get great numbers at low lift numbers with a v shaped port narrow at the bottom and wide at the top. The overlap is also very strong in the blowdown and the opening of the intake right off the seat they move fast, and I used Virago valves. I did some filling and the Coefficient of velocity is very strong and this points to a very aggressive flow and action right off the seat. The way that Shell Thuet did his ports is a good blueprint on what these ports like.@Oldnwiser

242cfm/0.30" intake and 200cfm/0.25" exhaust sounds kind of a lot.

Could you let us know at which test pressure which would shed some light to those numbers?

Thanks for the info.

Kind regards christian

Ps: yes those dellortos are pumpers as the pump is sitting behind the tower, while both of them seem to be somewhat of an older serious as they are spigot mounted and not rubber mounted with aluminum carburetor tops.

Last edited:

Hudriwudri

XS650 Addict

@Oldnwiser

With all due respect and i almost regret to say but if you measured 242cfm@0,3" at 28" with a 43mm ish intake valve then according to my experience i feel there is something wrong with your measured numbers in particular regarding the fact that the D-shape on your intake port is as i understand on the long turn side and not on the short side where the majority of flow goes (thus where the highest velocity is to be found and where there is the need to lower the velocity by increase of surface). I'm purposely not citing at this point the findings of eg Jerry branch or CR Axtell but it's just what I measured with a velocity probe in the intake port on a SF600 type flowbench.

Considering that a stock TT500/Xt500 head with the later 47mm valve flows bout 179cfm@25" at Maximum lift 242 seems to me sky high numbers.

I would have to look for my measurements of a stock xs head but I'm inclined to remember that the XS numbers were proportionally lower and worse due to a worse port shape in comparison to the XT500.

Kind regards and merry x-mas to everybody

Christian

Kind regards christian

With all due respect and i almost regret to say but if you measured 242cfm@0,3" at 28" with a 43mm ish intake valve then according to my experience i feel there is something wrong with your measured numbers in particular regarding the fact that the D-shape on your intake port is as i understand on the long turn side and not on the short side where the majority of flow goes (thus where the highest velocity is to be found and where there is the need to lower the velocity by increase of surface). I'm purposely not citing at this point the findings of eg Jerry branch or CR Axtell but it's just what I measured with a velocity probe in the intake port on a SF600 type flowbench.

Considering that a stock TT500/Xt500 head with the later 47mm valve flows bout 179cfm@25" at Maximum lift 242 seems to me sky high numbers.

I would have to look for my measurements of a stock xs head but I'm inclined to remember that the XS numbers were proportionally lower and worse due to a worse port shape in comparison to the XT500.

Kind regards and merry x-mas to everybody

Christian

Kind regards christian

Similar threads

- Replies

- 56

- Views

- 4K