The backer / spacer on the brake shaft can be installed backwards, it will make the wheel bind because will push the shoes against the side of the drum

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear axle help, drum won't rotate, chain slap also

- Thread starter kawabunga

- Start date

kawabunga

XS650 Addict

If you come up with a chain tensioner, pls post up what you have come up with. Wouldn’t you put the tensioner on the bottom which is where the slack would be? I have a problem of the chain rubbing on my reinforced swing arm and a tensioner would help eliminate this. Haven’t looked into it in any depth yet.

I already have one on the bottom, it’s not cutting it though. I’ve heard of people using two. Might try that.

Might wanna consider taking the existing tensioner off and see what happens. Could be the tension from that along with the new pivot position is setting up a resonate vibration in the chain. Couldn't hurt to try it...I already have one on the bottom, it’s not cutting it though. I’ve heard of people using two. Might try that.

kawabunga

XS650 Addict

5t, you are correct, my terminology is incorrect. My apologies for confusing everyone... When I mentioned the “drum” I was referring to the brake shoe plate/backing plate/brake plate. My bad. I had the terminology mixed up.

My drum, or hub, spins just fine when everything is installed. Never had any issues there.

My brake plate does not rotate when the axle is tightened. Which, according to everyone, should not rotate when the axle is tightened anyway. So that’s good news! I thought it was supposed to. Also, for reference, I took the brake stay arm off of my CB550, the drum does not rotate freely on that bike, like I thought it did. I think it may have spun once when I hit the brake without the stay in place on the lift. It moves a little when I spin the wheel and hit the brake but I can’t move it easily hand. I’m not entirely sure where I got the idea. Either way, thank you all for setting me straight on that!!

Now I can move on from that knowing it’s not a dilemma, and sort out my spacing issue so I can properly torque the axle down. After more research and discussion with an ex-motorcycle engineer, I’m thinking the axle/brake have nothing to do with my chain slapping around, but is more of a result of my suspension design, longer chain, and the engine characteristics. So that will still need to be dealt with. Got ideas? I’d love to hear them. I have a few experiments that I will be performing, and report back the results, once the bike is back together.

My drum, or hub, spins just fine when everything is installed. Never had any issues there.

My brake plate does not rotate when the axle is tightened. Which, according to everyone, should not rotate when the axle is tightened anyway. So that’s good news! I thought it was supposed to. Also, for reference, I took the brake stay arm off of my CB550, the drum does not rotate freely on that bike, like I thought it did. I think it may have spun once when I hit the brake without the stay in place on the lift. It moves a little when I spin the wheel and hit the brake but I can’t move it easily hand. I’m not entirely sure where I got the idea. Either way, thank you all for setting me straight on that!!

Now I can move on from that knowing it’s not a dilemma, and sort out my spacing issue so I can properly torque the axle down. After more research and discussion with an ex-motorcycle engineer, I’m thinking the axle/brake have nothing to do with my chain slapping around, but is more of a result of my suspension design, longer chain, and the engine characteristics. So that will still need to be dealt with. Got ideas? I’d love to hear them. I have a few experiments that I will be performing, and report back the results, once the bike is back together.

kawabunga

XS650 Addict

Might wanna consider taking the existing tensioner off and see what happens. Could be the tension from that along with the new pivot position is setting up a resonate vibration in the chain. Couldn't hurt to try it...

Im going to add that to my list of experiments

kawabunga

XS650 Addict

The backer / spacer on the brake shaft can be installed backwards, it will make the wheel bind because will push the shoes against the side of the drum

Gary, which part are you referring to exactly? I’m not confident I know which one you’re talking about.

kawabunga

XS650 Addict

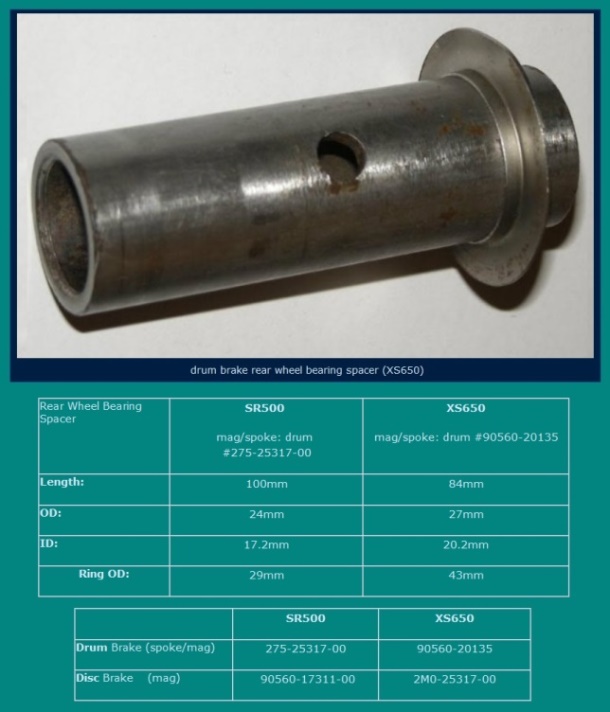

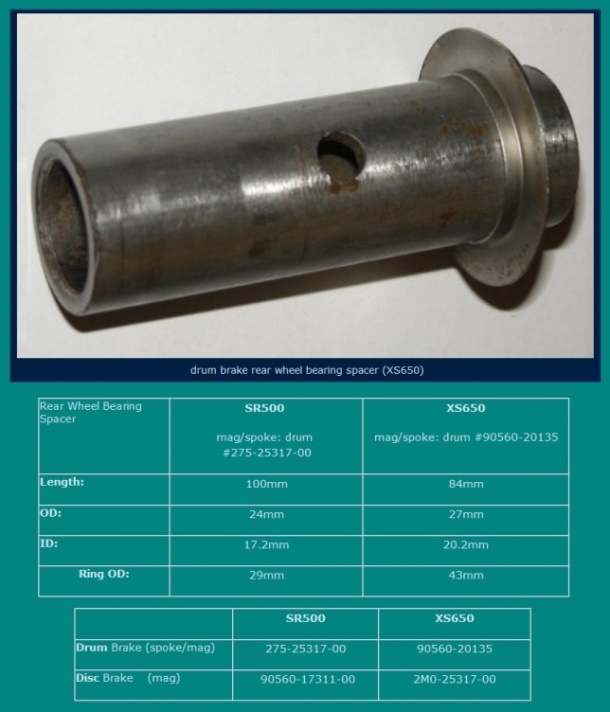

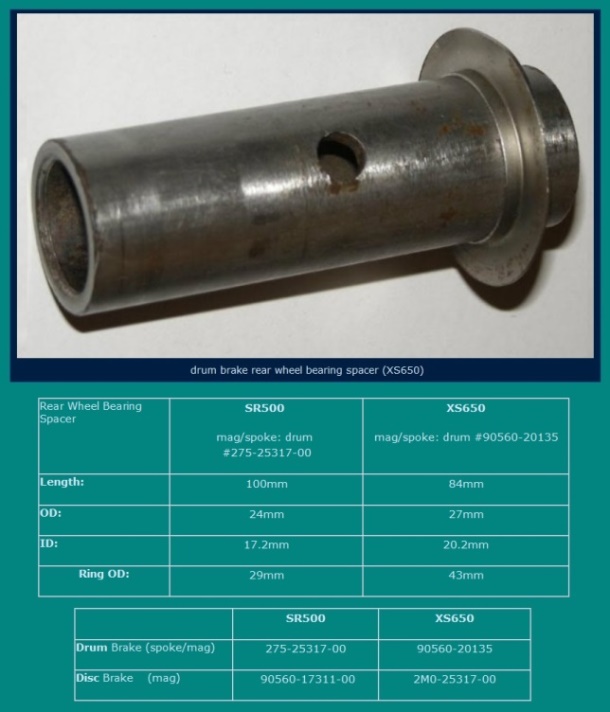

Speaking of which, I measured that built-in spacer in three I have, a '77, '78, and an '80-'83 one. They all measure pretty much the same and seem to match what you found on yours. The spacer sticks out on the inside about 6.5 to just over 7mm, and the overall length of the spacer from the inside edge to the outer face is about 32mm.

Thank you for measuring those!

I also measured the overall length and found it to be roughly 32mm as well.

Would you mind doing a quick measure of the rest of the spacers?

Here’s what I found:

The left side spacer with the dust cover - 31.1mm

Top hat spacer - 20.9mm

Spacer between bearings - 84mm

The right hand spacer outside the brake plate - 25mm

kawabunga

XS650 Addict

Machine, I believe the brake components are from ‘79, but I can’t be sure. Will have to check.

stinky78

XS650 Addict

I think the main problem with the suspension design is having the pivot point below the bottom run of the chain rather than between top and bottom like normal, that and the distance of the swing arm pivot from the front sprocket, the normal set up doesn’t give as much leverage to try to shorten the chain, though you do get squat under acceleration, it’s not as exaggerated as in this set up, now it’s built it’s a bit hard to do anything about the design, just need to find ways to work around it’s short comings, when I first looked I didn’t see the tensioner, do you find you get a lot of squat/compression of suspension under acceleration?

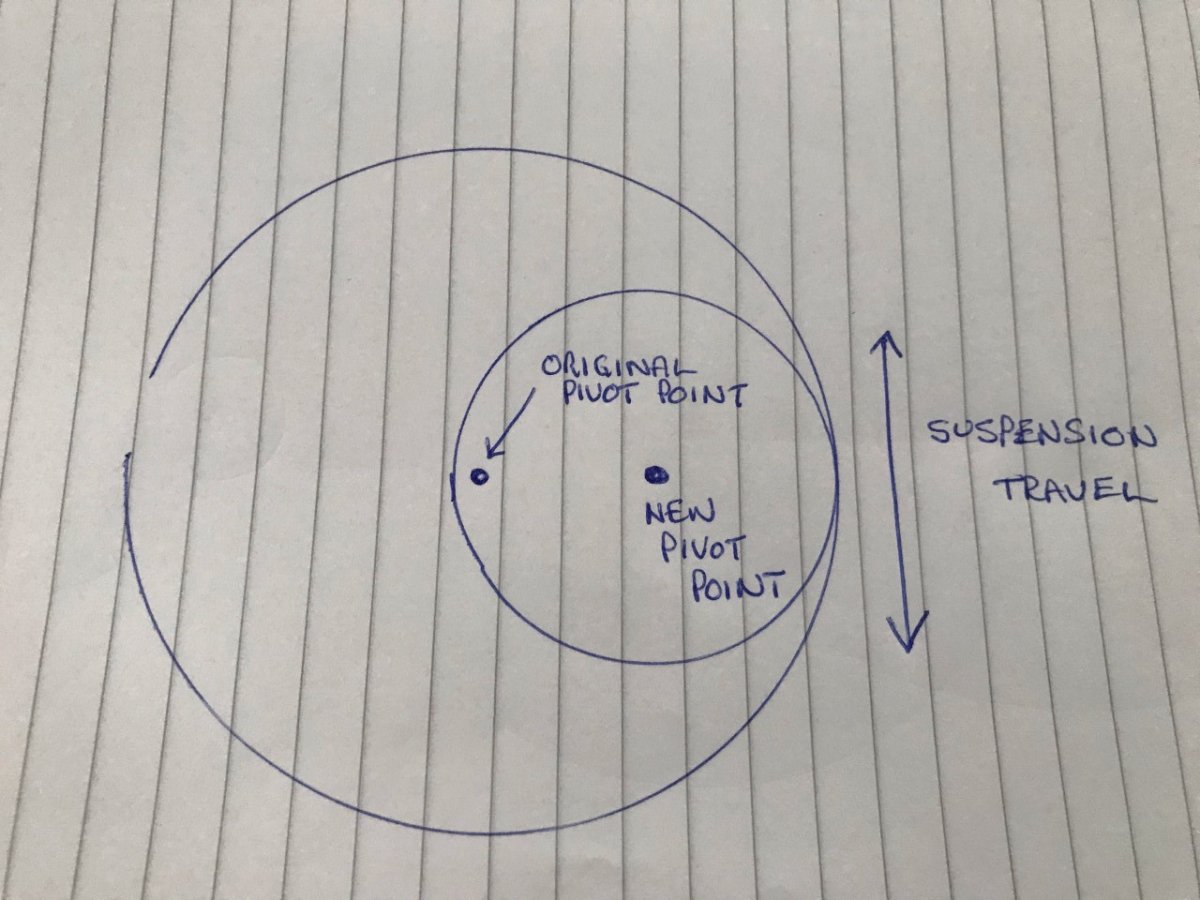

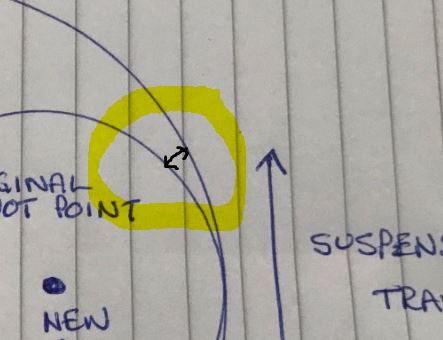

I'm sure if I could find my compasses and could remember all that stuff about radians and arctans and cosines I could work it out but here goes.

From the picture above you seem to have moved the pivot point of the new "swinging arm" considerably rearward of the pivot point of the old swinging arm. This means that the radius of the circles it describes is much smaller, and the arc of the circle it describes is tighter.

This means that as the suspension compresses the arc of the new arrangement departs from the path of the old arrangement and moves inboard.

Your chain slack may be coming from the bit I've marked in yellow.

To not have any additional slack introduced as the suspension moves the pivot point would have be the same as the centre of the front sprocket. Obviously, this is difficult to engineer so normally the swing arm pivot point is just kept as close to the sprocket as possible.

Of course, I could be wrong.

From the picture above you seem to have moved the pivot point of the new "swinging arm" considerably rearward of the pivot point of the old swinging arm. This means that the radius of the circles it describes is much smaller, and the arc of the circle it describes is tighter.

This means that as the suspension compresses the arc of the new arrangement departs from the path of the old arrangement and moves inboard.

Your chain slack may be coming from the bit I've marked in yellow.

To not have any additional slack introduced as the suspension moves the pivot point would have be the same as the centre of the front sprocket. Obviously, this is difficult to engineer so normally the swing arm pivot point is just kept as close to the sprocket as possible.

Of course, I could be wrong.

kawabunga

XS650 Addict

I think the main problem with the suspension design is having the pivot point below the bottom run of the chain rather than between top and bottom like normal, that and the distance of the swing arm pivot from the front sprocket

The pivot point is between the top and bottom rung of the chain. The angle this photo is taken at is a bit deceiving.

do you find you get a lot of squat/compression of suspension under acceleration?

Some, but not much.

I'm sure if I could find my compasses and could remember all that stuff about radians and arctans and cosines I could work it out but here goes.

From the picture above you seem to have moved the pivot point of the new "swinging arm" considerably rearward of the pivot point of the old swinging arm. This means that the radius of the circles it describes is much smaller, and the arc of the circle it describes is tighter.

View attachment 172781

This means that as the suspension compresses the arc of the new arrangement departs from the path of the old arrangement and moves inboard.

View attachment 172782

Your chain slack may be coming from the bit I've marked in yellow.

To not have any additional slack introduced as the suspension moves the pivot point would have be the same as the centre of the front sprocket. Obviously, this is difficult to engineer so normally the swing arm pivot point is just kept as close to the sprocket as possible.

Of course, I could be wrong.

Dave, you may not be 100% correct, but you're definitely not wrong. I did move the swingarm pivot rearward, and that does change the radius and how it interacts with the countershaft significantly. The height of the pivot plays a huge part in that as well. And the suspension travel direction...and the amount of suspension travel...and the shock pivot points...and the distance from the swingarm pivot to the axle...and so on. I'm not a mechanical engineer, I did my best with the knowledge I had at the time. The suspension works just fine as is but it has created the chain slack issue. Since it's all welded together now it's quite difficult to do much about the design without basically starting over completely. I understand why it's doing what it's doing, I'm looking for ways to limit its affect.

I understand why it's doing what it's doing, I'm looking for ways to limit its affect.

I'm not an engineer, and I'm not implying any criticism.

Dave

kawabunga

XS650 Addict

I'm not an engineer, and I'm not implying any criticism.The work is outstanding. Far beyond my abilities. Hope you get it sorted.

Dave

All good, Dave. I appreciate your input. Sorry if my reply came across as snippy, I didn’t mean for it to be. If anything, I’m just more frustrated with myself for creating this problem on my own accord. If only I knew then what I know now...

You've not created a problem. Its a "development opportunity". You think the guy who thought up the points ignition was disappointed by burning points and gave up? Nope, he added a condensor to solve the problem. Bikes don't start easily with static timing. So a doo-dad was added to retard it for start up. Heck, the XS1 has a decompressor. I'd like to have been a fly on the wall at that first test start before the "fix". (BTW - The first time I ever saw the starting cable pull and heard one start on one cylinder I thought it was the coolest thing I'd ever heard. I was hooked.)

You'll sort the problem and you'll be able to say , "The design of the suspension keeps the back end clean but of course I've had to add a chain tensioner top and bottom to take up the slack at full compression."

How cool is that?

You'll sort the problem and you'll be able to say , "The design of the suspension keeps the back end clean but of course I've had to add a chain tensioner top and bottom to take up the slack at full compression."

How cool is that?

stinky78

XS650 Addict

sorry! my mistake, I take back what I said about the pivot point, I thought the bolt below it was the pivot, was viewing on my phone while at work, like Dave I’m also not being critical, I”d be to scared to undertake a project like that myself, just trying to put ideas out there that might help, the only thing I can think of is to use a shock with adjustable compression damping, if your current one doesn’t have it that is.

I don't have a wheel hub apart at the moment to check the internal spacer lengths, but I managed to find that info (or links to it) on the site here. For you, it's sorta good news, bad news. Good news - your internal spacers appear to be correct and OK. Bad news then is they aren't the source of your binding or rubbing .....

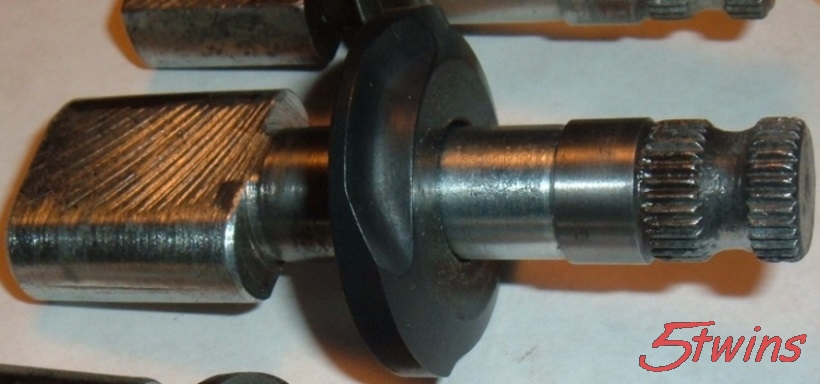

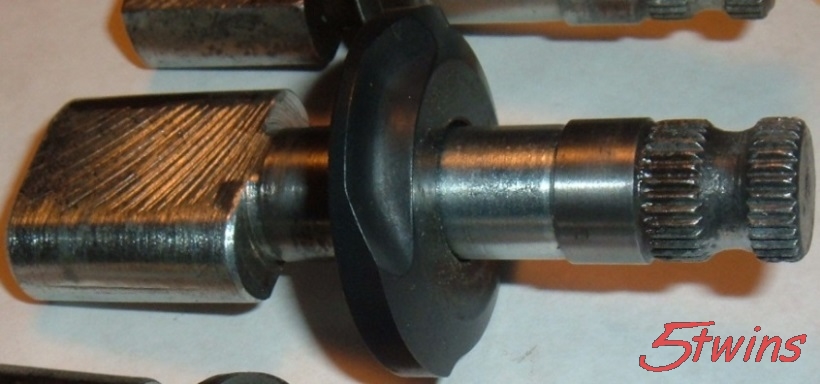

So, it may come down to, as Machine mentioned, the assembly and installation of the brake camshaft and it's funky shaped spacer washer into the brake plate. '74-'79 brake plate castings had a boss below the camshaft hole for an electric brake wear switch. Even though the switch was discontinued about mid '77, the casting remained .....

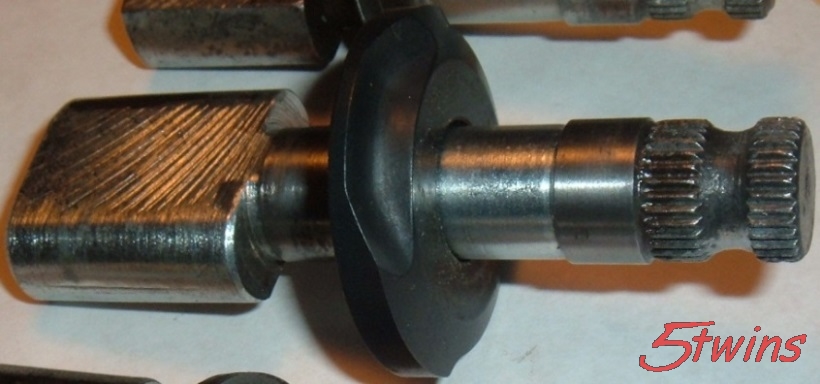

On the funky spacer washer used, the top side was cut out for the camshaft to fit down into and the bottom side was dished out on one side to clear the plate casting .....

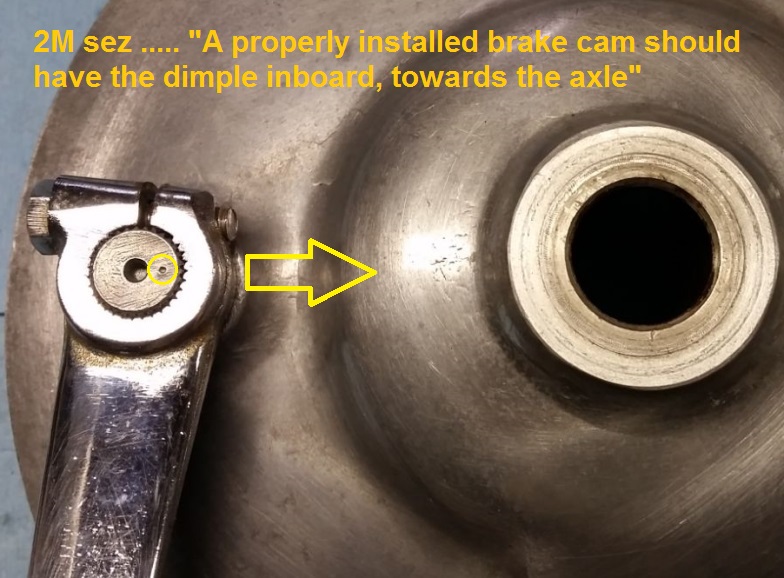

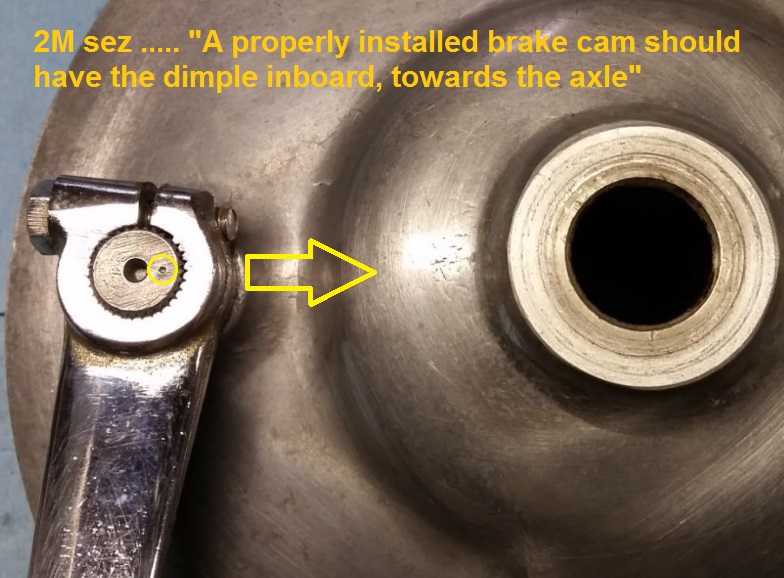

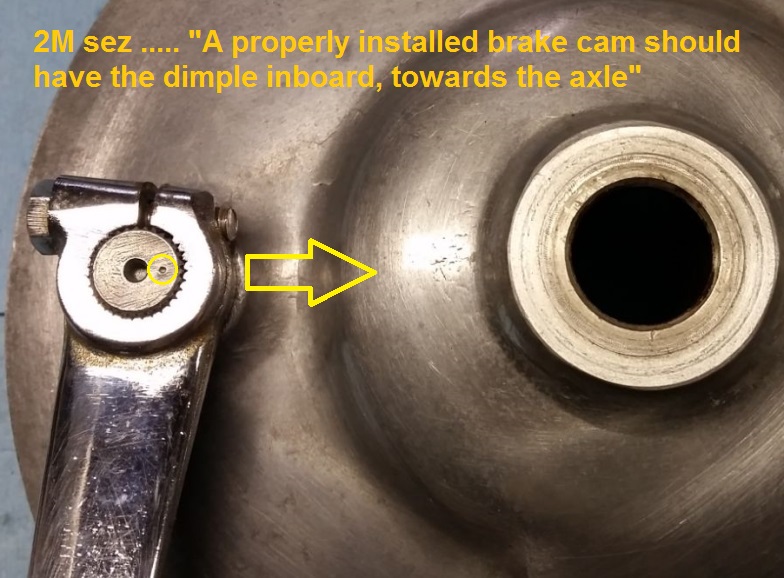

That dished out section must face down towards the bottom of the brake plate. One more little thing on the install. This doesn't have anything to do with rubbing but rather best braking operation. The camshaft is not symmetrical, one side of the cam portion extends off center slightly more than the other. This moves one shoe slightly more than the other to compensate for the difference in distance between the shoe pivot point and the contact point of the cam to the shoe. The difference is so small, you can't see it with the naked eye so Yamaha marked the outside end of the shaft with a dot. This dot should be faced in, towards the axle .....

So, it may come down to, as Machine mentioned, the assembly and installation of the brake camshaft and it's funky shaped spacer washer into the brake plate. '74-'79 brake plate castings had a boss below the camshaft hole for an electric brake wear switch. Even though the switch was discontinued about mid '77, the casting remained .....

On the funky spacer washer used, the top side was cut out for the camshaft to fit down into and the bottom side was dished out on one side to clear the plate casting .....

That dished out section must face down towards the bottom of the brake plate. One more little thing on the install. This doesn't have anything to do with rubbing but rather best braking operation. The camshaft is not symmetrical, one side of the cam portion extends off center slightly more than the other. This moves one shoe slightly more than the other to compensate for the difference in distance between the shoe pivot point and the contact point of the cam to the shoe. The difference is so small, you can't see it with the naked eye so Yamaha marked the outside end of the shaft with a dot. This dot should be faced in, towards the axle .....

Just had a look at the dimple on the splined shaft and mine is pointing the wrong way. Will flip it around once I get the center stand installed. Can I expect a noticeable improvement in the rear braking? Thx for the tip!I don't have a wheel hub apart at the moment to check the internal spacer lengths, but I managed to find that info (or links to it) on the site here. For you, it's sorta good news, bad news. Good news - your internal spacers appear to be correct and OK. Bad news then is they aren't the source of your binding or rubbing .....

So, it may come down to, as Machine mentioned, the assembly and installation of the brake camshaft and it's funky shaped spacer washer into the brake plate. '74-'79 brake plate castings had a boss below the camshaft hole for an electric brake wear switch. Even though the switch was discontinued about mid '77, the casting remained .....

On the funky spacer washer used, the top side was cut out for the camshaft to fit down into and the bottom side was dished out on one side to clear the plate casting .....

That dished out section must face down towards the bottom of the brake plate. One more little thing on the install. This doesn't have anything to do with rubbing but rather best braking operation. The camshaft is not symmetrical, one side of the cam portion extends off center slightly more than the other. This moves one shoe slightly more than the other to compensate for the difference in distance between the shoe pivot point and the contact point of the cam to the shoe. The difference is so small, you can't see it with the naked eye so Yamaha marked the outside end of the shaft with a dot. This dot should be faced in, towards the axle .....

kawabunga

XS650 Addict

You've not created a problem. Its a "development opportunity". You think the guy who thought up the points ignition was disappointed by burning points and gave up? Nope, he added a condensor to solve the problem. Bikes don't start easily with static timing. So a doo-dad was added to retard it for start up. Heck, the XS1 has a decompressor. I'd like to have been a fly on the wall at that first test start before the "fix". (BTW - The first time I ever saw the starting cable pull and heard one start on one cylinder I thought it was the coolest thing I'd ever heard. I was hooked.)

You'll sort the problem and you'll be able to say , "The design of the suspension keeps the back end clean but of course I've had to add a chain tensioner top and bottom to take up the slack at full compression."

How cool is that?

Dave, thank you for framing it differently. Most great things weren't great on their first iteration. I just wish I would have paid more attention and done a bit more research before welding it all together. Hind-sight is hind-sight I guess...

Admittedly, I'm a bit hard on myself; my wife tells me that a lot. It feels like a failure when I didn't get it "right" this time around. But, it's my first attempt at suspension and I had to finish the build before February for a show so I wasn't able to do any real world testing in the dead of winter. I guess I just feel a bit foolish admitting my error. I need to lighten up.

sorry! my mistake, I take back what I said about the pivot point, I thought the bolt below it was the pivot, was viewing on my phone while at work, like Dave I’m also not being critical, I”d be to scared to undertake a project like that myself, just trying to put ideas out there that might help, the only thing I can think of is to use a shock with adjustable compression damping, if your current one doesn’t have it that is.

No worries, stinky. I appreciate the suggestions. I spoke to a sales rep for Race Tech Suspension about getting a custom shock built, because that's what I really need here, but it's not in the budget right now. They get expensive, quick! In the meantime I might try to find a different shock but it's a bit of a needle in a haystack situation finding another random shock with the same dimensions. Unless someone out there has a cross-reference tool?

I don't have a wheel hub apart at the moment to check the internal spacer lengths, but I managed to find that info (or links to it) on the site here. For you, it's sorta good news, bad news. Good news - your internal spacers appear to be correct and OK. Bad news then is they aren't the source of your binding or rubbing .....

Glad to hear my spacers are good. Thanks for finding that info!

So, it may come down to, as Machine mentioned, the assembly and installation of the brake camshaft and it's funky shaped spacer washer into the brake plate. '74-'79 brake plate castings had a boss below the camshaft hole for an electric brake wear switch. Even though the switch was discontinued about mid '77, the casting remained .....

On the funky spacer washer used, the top side was cut out for the camshaft to fit down into and the bottom side was dished out on one side to clear the plate casting .....

That dished out section must face down towards the bottom of the brake plate. One more little thing on the install. This doesn't have anything to do with rubbing but rather best braking operation. The camshaft is not symmetrical, one side of the cam portion extends off center slightly more than the other. This moves one shoe slightly more than the other to compensate for the difference in distance between the shoe pivot point and the contact point of the cam to the shoe. The difference is so small, you can't see it with the naked eye so Yamaha marked the outside end of the shaft with a dot. This dot should be faced in, towards the axle .....

Well, I did not know that about the rear brake.

My washer was oriented correctly, so that's cool.

My brake cam though, I'm not sure mine has the dot on it. It's very faint if it is there, or it looks like it could have just smashed at some point. I rotated it so the "dot" is forward. Does it look like the right marking?

I got all the bearings and spacers reinstalled. Before putting it all together I smoothed out some of the wear on the spacers with light sanding. Didn't take any real material off though. Everything went back together as expected.

No pinching, which there never was any because of my incorrect terminology... The brake plate didn't, and still does not, rotate once the axle is torqued, so that's good. The hub itself spins smooth as a whistle. AND, I was able to get the axle nut torqued to 70 ft/lb! No binding, the chain adjustment plate didn't want to spin and the axle didn't bottom on the chain adjuster plate. It was a matter of playing around with washer widths and arraignment to find the correct spacing and alignment. The TC Bros. hardtail axle plates are significantly thinner than the ones on the OEM swingarm, so it throws things off when using the stock chain adjusters.

I have not yet gone for a test ride to see if a properly torqued axle makes a difference with the chain slap. I don't expect it to, but I've made presumptions before and been wrong... Will report back after some riding and testing.

Thank you for all the help so far!

Yes, that looks like the dot. Sometimes it's pretty faint. As far as it majorly improving the braking, that will depend on how long it was run incorrectly. If run in the wrong position for a long time, the shoes will wear in that way and switching the cam around may not make much of a difference at first. But these shoes are pretty slow wearing. I had mine wrong on my TX750 wheel for several years. It didn't brake very well. I now have it "fixed" and the braking is much improved. Seems the shoes didn't wear much when I had it wrong. I have another wheel from a '77. It had the best braking of any rear wheel I have, and inspecting it showed it was assembled wrong. But that's the way I got it and I guess the way it was always run, so apparently the shoes eventually bedded in that way. I've switched the cam around now and it doesn't brake as well, lol. I'm hoping more miles will help, or maybe I'll swap the shoes top to bottom, that might help.