REPETE

XS650 Addict

Good Morning -

I reached a stumbling block that has me perplexed .

I’m really hoping I’m simply missing something basic - I’ll take the embarrassment to get over the hump.

I really want to get this started today and timed with the timing light.

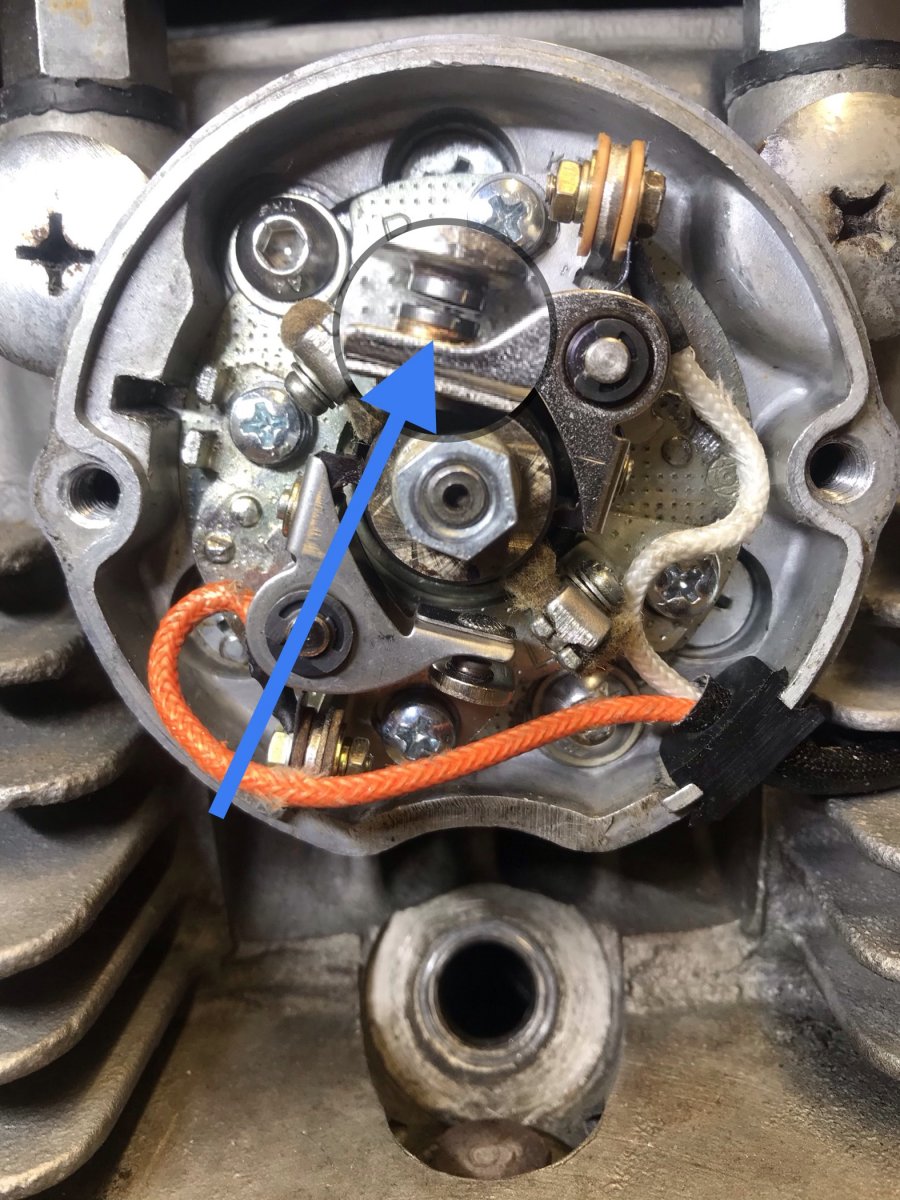

The breaker points have been installed as shown and with the point gap in an open position I’m still getting continuity across the two sides of the breaker....

no change whether open or closed.

I keep reviewing the installation and for the life of me cannot see anything wrong with it.

But yet, there must be!

As a check I opened and closed a set of the old points while checking continuity and as I expected the continuity is broken when the points are opened. But not with my installed points.

At this point I’m just wasting my time and not getting anywhere.

This is occurring in both sets, so it wouldn’t be defective breakers.

What could be causing this?

What am I not seeing?

I sure could use some help on this one so to get back on track with original issue.

And if I missed something really obvious, my feelings won’t be hurt if I become today’s entertainment!

Thanks all

Pete

I reached a stumbling block that has me perplexed .

I’m really hoping I’m simply missing something basic - I’ll take the embarrassment to get over the hump.

I really want to get this started today and timed with the timing light.

The breaker points have been installed as shown and with the point gap in an open position I’m still getting continuity across the two sides of the breaker....

no change whether open or closed.

I keep reviewing the installation and for the life of me cannot see anything wrong with it.

But yet, there must be!

As a check I opened and closed a set of the old points while checking continuity and as I expected the continuity is broken when the points are opened. But not with my installed points.

At this point I’m just wasting my time and not getting anywhere.

This is occurring in both sets, so it wouldn’t be defective breakers.

What could be causing this?

What am I not seeing?

I sure could use some help on this one so to get back on track with original issue.

And if I missed something really obvious, my feelings won’t be hurt if I become today’s entertainment!

Thanks all

Pete