Yeah... that's closer than I would have guessed, but it makes sense. The closer the magnetic field is to the stators iron cores, the more electricity is generated.Wow! I didn’t realize they operated in such close tolerances.

View attachment 135944

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rotor Winding Tooling

- Thread starter Jim

- Start date

Yup, I think is a relationship of the inverse squared type: 1/(gap)**2.

So, if the gap is cut in half, the flux (which determines the current) is four times as much ( 1/0.5 x 1/0.5 = 4 ).

So - having a smaller gap is really important to alternator system performance.

So, if the gap is cut in half, the flux (which determines the current) is four times as much ( 1/0.5 x 1/0.5 = 4 ).

So - having a smaller gap is really important to alternator system performance.

I don't have calipers with deep enough jaws...

Jim, here's a trick.

From here.

Post #19

http://www.xs650.com/threads/650-rear-drum-brake-plates.51046/#post-582480

... I stuffed a tooth pick 'tween em and measured the crush. Gap is .028". So.... 14 thou. wobble would rub. That ain't much folks...

Pretty close in there. Like a blender.

Imagine.

Coupla attachments, a spout,

and you could make fruit smoothies while camping...

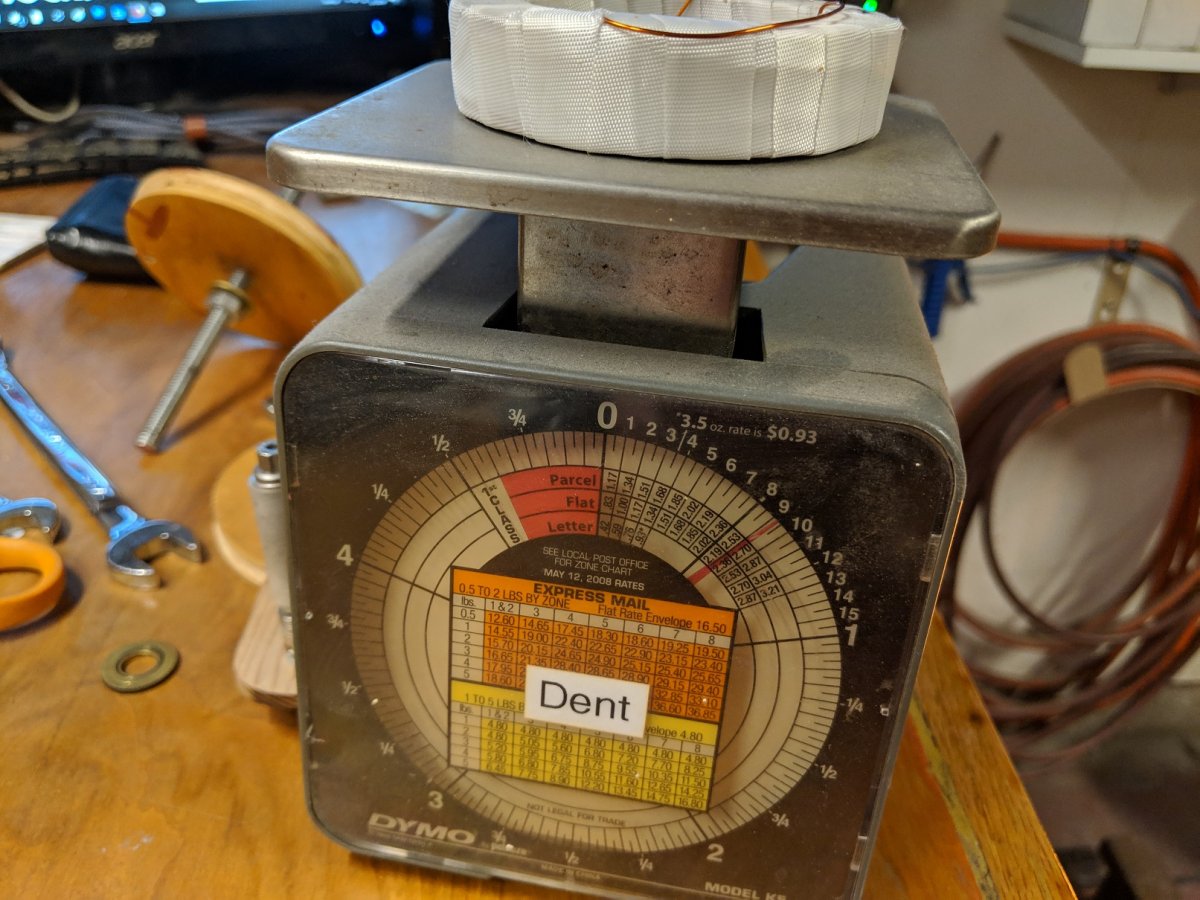

450 turns of 22ga. copper......

Weighs just over a half a pound.

Mass production....

Weighs just over a half a pound.

Mass production....

Very tidy Jim!

Thanks Pete!

So... I freely admit I ain't the sharpest knife in the drawer.... but I do learn.

If you want a rewound rotor to run true, ya gotta start with one that runs true.

If you want a rewound rotor to run true, ya gotta start with one that runs true.

Very nice! There you go thinking like an machinist again!

Reading this about rebuilding the rotor jogged my memory and got me thinking about problem I had with either a RD200 or was it the RD400?

Any how it was having a charging problem and I opened up the side of the engine to find that the slip ring plate had come loose on the rotor and actually was cracked in a couple places, wires were still intact.

Not knowing any better I managed to dig out the epoxy that covered the attaching screws . Seem to recall the screw hole threads were buggered up in the rotor so I tapped them out for machine screw sizes. Then I mixed up some epoxy and worked it in the cracks in the slip ring backer and down between the rotor and the backer and then installed new screws.

After epoxy set up over night I managed to chuck it up in the lathe at work clamping on the out side of the rotor and took a light cut to true up the slip rings. To my surprise it actually worked when I was done!

Any how it was having a charging problem and I opened up the side of the engine to find that the slip ring plate had come loose on the rotor and actually was cracked in a couple places, wires were still intact.

Not knowing any better I managed to dig out the epoxy that covered the attaching screws . Seem to recall the screw hole threads were buggered up in the rotor so I tapped them out for machine screw sizes. Then I mixed up some epoxy and worked it in the cracks in the slip ring backer and down between the rotor and the backer and then installed new screws.

After epoxy set up over night I managed to chuck it up in the lathe at work clamping on the out side of the rotor and took a light cut to true up the slip rings. To my surprise it actually worked when I was done!

.... and even more tooling.

To balance the rotor after rewinding, I'm using the drill press. I don't want to use a drill press vise for fear of cracking the 40 yr. old phonolic plate. Here's the quick and easy rotor vise....

To balance the rotor after rewinding, I'm using the drill press. I don't want to use a drill press vise for fear of cracking the 40 yr. old phonolic plate. Here's the quick and easy rotor vise....

Ooohhhh....pretty!!

JimTo balance the rotor after rewinding

Have you checked any of the rotors for balance before you rewound them?

Reason I ask is a long time ago I used to rebuild alternators. I changed a few coils and never had a balance problem. I just made sure I indexed them the way they originally were. I'm just curios how well Mama Yama balanced them.

Yeah... actually I have. Kinda surprising, but even some of the factory ones have a heavy spot on the knife edge. Not sure what to make of that.... either my knife edge works extremely well, or Yamaha didn't have very tight balance tolerances. I don't think age would have an affect so..... who knows.......checked any of the rotors for balance before you rewound them?

In the end, these motors shake so bad I don't think rotor balance has much of an affect.... mostly just OCD on my part.

Better balancing than the original sure can't hurt tho

Better balancing than the original sure can't hurt tho

ZACKLEY!!!

Reason I asked is that if they were all out of balance the same they might have used the rotor to counterbalance the crank. Just food for thought.

Reason I asked is that if they were all out of balance the same they might have used the rotor to counterbalance the crank. Just food for thought.

....hmmmm...could be but I’d guess that the cranks are balanced well before the engine is assembled and waaaayyyy before the alternator rotor is installed.

They're not. Some don't move at all on the knife edge..........if they were all out of balance the same they might have used the rotor to counterbalance the crank.

And they could have used the rotor to fine tune things.....hmmmm...could be but I’d guess that the cranks are balanced well before the engine is assembled and waaaayyyy before the alternator rotor is installed.

Ah maybe not these engines always had more than their share of vibrations.

I think Jim's on the right track.

Similar threads

- Replies

- 35

- Views

- 5K