I acquired a rotor many years ago from a friend on the Micapeak email list. It was well under 5 ohms. 18 years on it, so far.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rotor Winding Tooling

- Thread starter Jim

- Start date

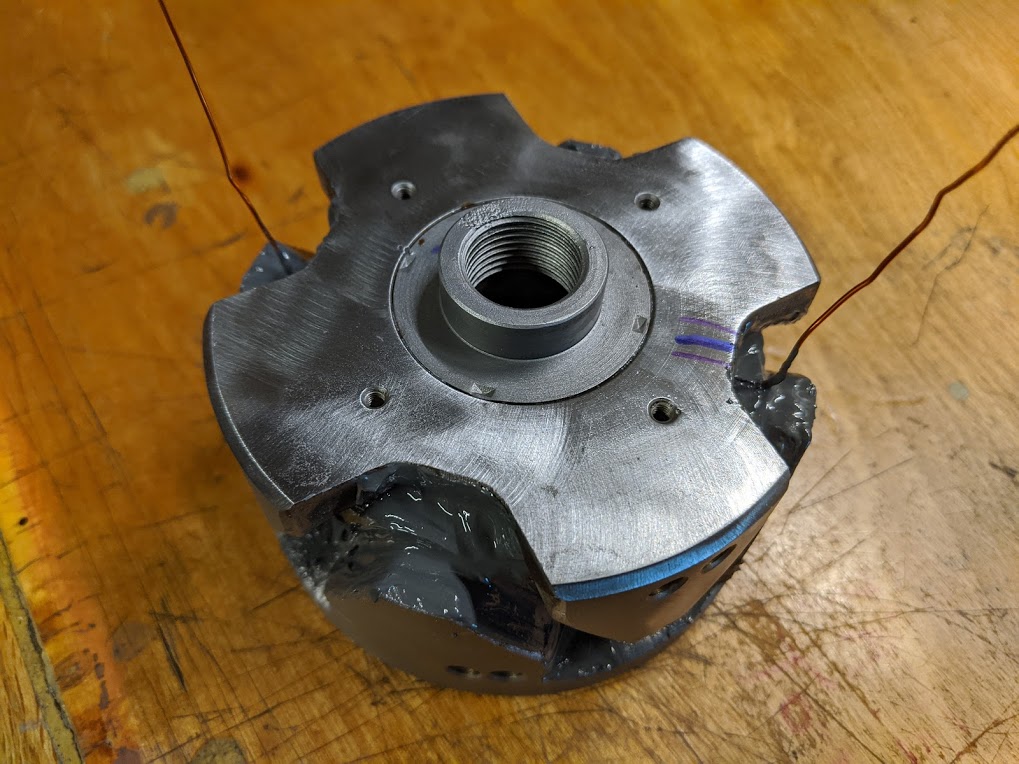

Making the winding form was straightforward. All I had to do was make a new inner piece. The rest of it worked just fine.

Cranked out 500 turns.

Wrapped in fiberglass tape just like the XS coils (didn't get a pic) and pressed it back together.

It's not splined like the XS rotors, so I made a punch mark when I took it apart. Wound up nailing the alignment, so balance should be pretty close.

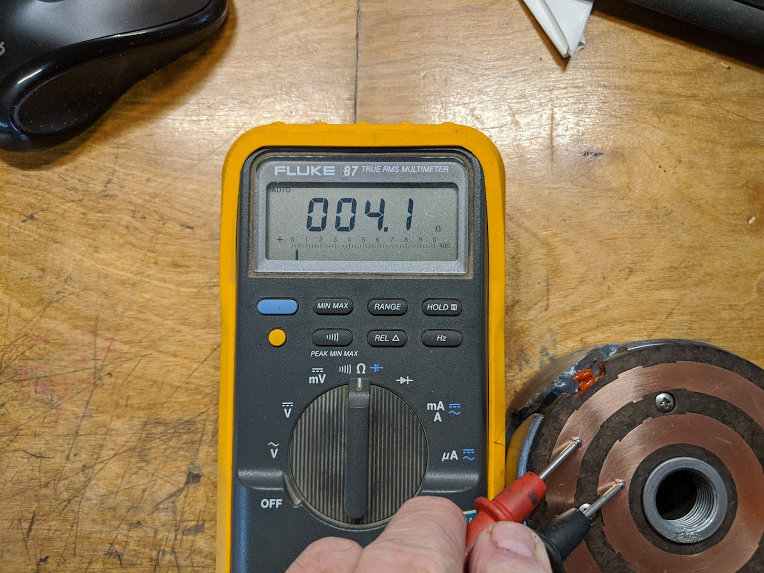

Was shootin' for 3.8 to 4Ω... ♬ ♬ nailed it ♬ ♬

I'll let the JB Weld harden overnight and finish putting it together. The taper on the hole turns out to be identical to the XS taper, so balance and runout tooling will work for this rotor.

Cranked out 500 turns.

Wrapped in fiberglass tape just like the XS coils (didn't get a pic) and pressed it back together.

It's not splined like the XS rotors, so I made a punch mark when I took it apart. Wound up nailing the alignment, so balance should be pretty close.

Was shootin' for 3.8 to 4Ω... ♬ ♬ nailed it ♬ ♬

I'll let the JB Weld harden overnight and finish putting it together. The taper on the hole turns out to be identical to the XS taper, so balance and runout tooling will work for this rotor.

I like the punch marks for alignment. Sometimes its the simple things similar to this that help greatly!

Which CB750 is this for? The DOHC 750 from '79 up, or the SOHC CB750 built up till '78?

The DOHC 750 and 900 have a big following now, they'll always be looking for rotors.

The DOHC 750 and 900 have a big following now, they'll always be looking for rotors.

I believe it's for the DOHC750 Scott.

Hey, Jim, you've got quite the cottage industry in the works there. A "side job" that could pay for all your other projects (and keep you off the streets at night!  ). Catalog all you winding forms and tooling, keep detailed notes (i'm guessing you already have), and you'll have built the "better mouse trap" the world beats a path to your door for....

). Catalog all you winding forms and tooling, keep detailed notes (i'm guessing you already have), and you'll have built the "better mouse trap" the world beats a path to your door for....

). Catalog all you winding forms and tooling, keep detailed notes (i'm guessing you already have), and you'll have built the "better mouse trap" the world beats a path to your door for....

). Catalog all you winding forms and tooling, keep detailed notes (i'm guessing you already have), and you'll have built the "better mouse trap" the world beats a path to your door for....

You sure do nice work Jim!

Sweet Jim!

Those DOHC STATORS were fragile, bump the RH crank cover and plan on a new stator.

Those DOHC STATORS were fragile, bump the RH crank cover and plan on a new stator.

Grumpy32

XS650 Member

Jim is correct Scott, that rotor is for the DOHC Honda 4's. It was used on the cb750's, 900's, and 1000's, yrs 1979-83.Which CB750 is this for? The DOHC 750 from '79 up, or the SOHC CB750 built up till '78?

The DOHC 750 and 900 have a big following now, they'll always be looking for rotors.

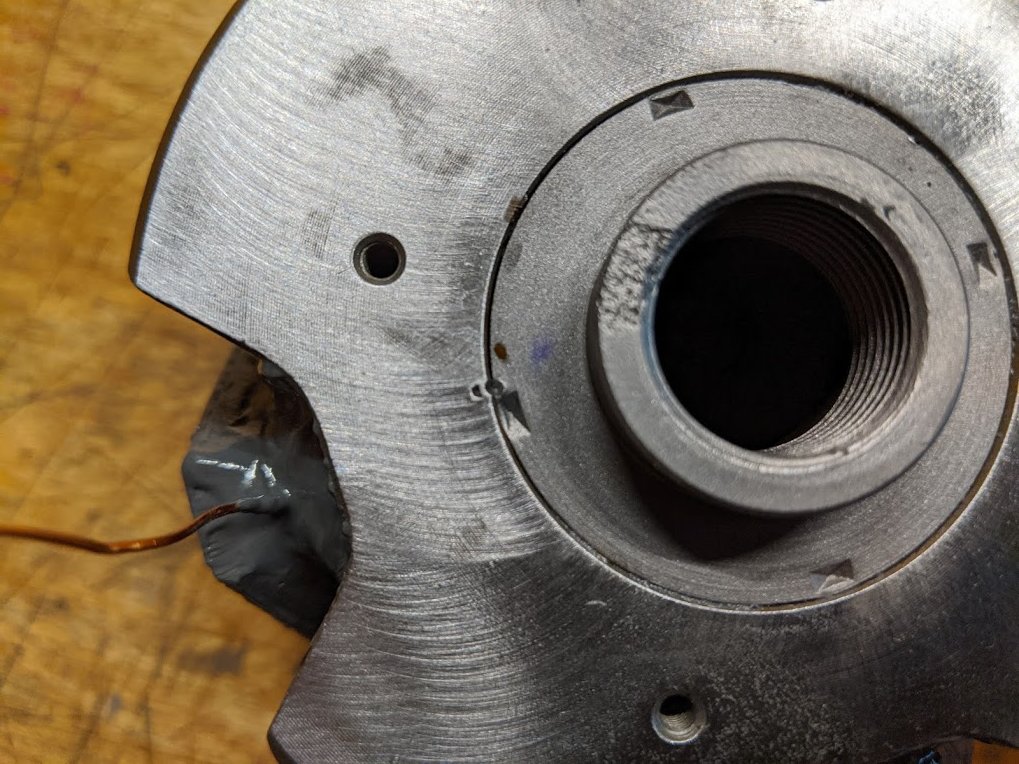

Slip ring looked pretty rough to start with...

Much better now. All back together. As with the XS rotors, there's a slight increase in resistance when it's assembled. I'm guessin' there's a bit of inductive reactance going on when the iron core is pressed together. Still... 4.1 Ω is pretty close to what the guy's on the CB site said was preferred. According to them, the book calls for 4.5 Ω, but their years of experience has showed them that 3.8 to 4 Ω makes for a better charging system. 4.1 will do.

Runout is good, but I can't check the balance because my balance shaft is too light for this much heavier rotor. I'm currently epoxying extra weight to it.

Please stand by...

Much better now. All back together. As with the XS rotors, there's a slight increase in resistance when it's assembled. I'm guessin' there's a bit of inductive reactance going on when the iron core is pressed together. Still... 4.1 Ω is pretty close to what the guy's on the CB site said was preferred. According to them, the book calls for 4.5 Ω, but their years of experience has showed them that 3.8 to 4 Ω makes for a better charging system. 4.1 will do.

Runout is good, but I can't check the balance because my balance shaft is too light for this much heavier rotor. I'm currently epoxying extra weight to it.

Please stand by...

Last edited:

Grumpy32

XS650 Member

Excellent! I'm standing by...

I'm standing by...

Thought something was odd. Went back and looked at the pics. Yesterday was 3.9 Ω and 4.1 Ω today... but in both cases, the coil was already in the rotor. Hmmm.... different temps maybe? Just rechecked it...

Guess we'll call it 3.9 to 4.1... depending on how I hold my tongue.

Guess we'll call it 3.9 to 4.1... depending on how I hold my tongue.

All my meters drift down slowly for about 3-4 seconds before they settle when ohming rotors.

"Temperature Coefficient of Copper. The Temperature Coefficient of Copper (near room temperature) is +0.393 percent per degree C. This means if the temperature increases 1°C, the resistance will increase 0.393%. ... The wire resistance will go up 0.00255 ohms (10 degrees * 0.00393 per degree * 0.0649 ohms = 0.00255 ohms)."

"Temperature Coefficient of Copper. The Temperature Coefficient of Copper (near room temperature) is +0.393 percent per degree C. This means if the temperature increases 1°C, the resistance will increase 0.393%. ... The wire resistance will go up 0.00255 ohms (10 degrees * 0.00393 per degree * 0.0649 ohms = 0.00255 ohms)."

Temperature Coefficient of Copper. The Temperature Coefficient of Copper (near room temperature) is +0.393 percent per degree C. This means if the temperature increases 1°C, the resistance will increase 0.393%. ... The wire resistance will go up 0.00255 ohms (10 degrees * 0.00393 per degree * 0.0649 ohms = 0.00255 ohms).

Yeah, mine too. All my readings are after 20-30 seconds.All my meters drift down slowly for about 3-4 seconds before they settle when ohming rotors.

A fresh Jims rewind rotor , ready to spin forever !

-R

Honda CB750 rotor balanced, clear coated and ready to ship.

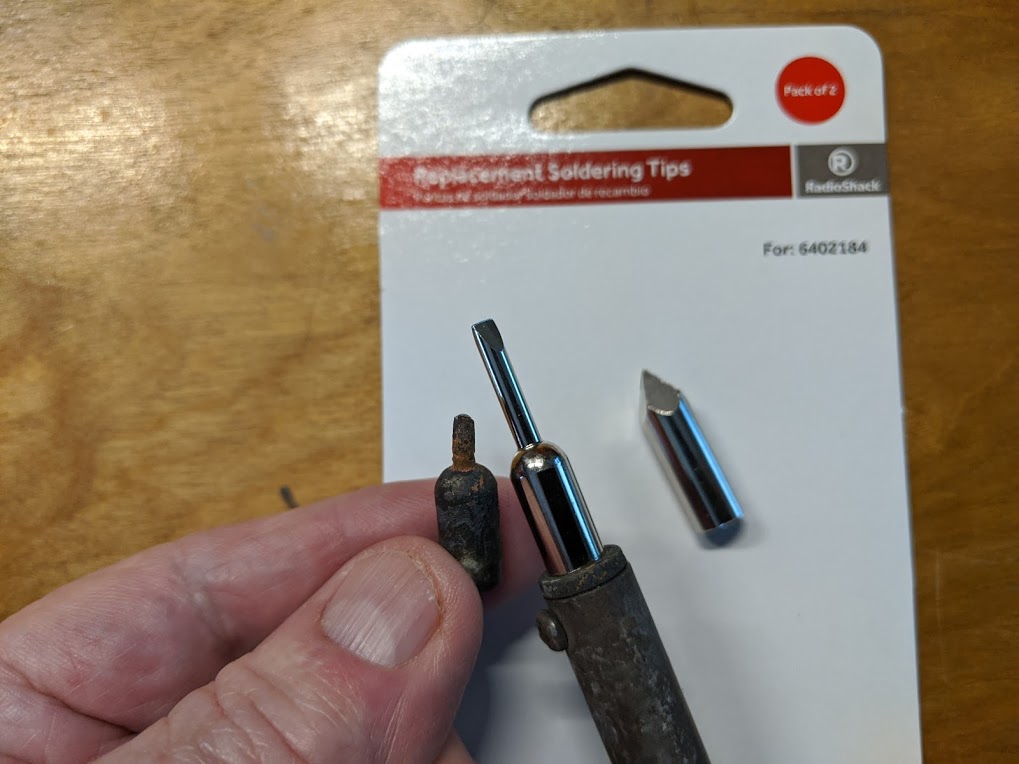

I've had this iron since my Air Force days... and I retired in 94. I guess we can say this tip gave it's all.

Is it easier to count turns or simply use up a measured length of wire? The end result will be the same.

Similar threads

- Replies

- 35

- Views

- 5K