Counting the turns only requires looking at the counter periodically. Yeah, measuring the length would also work, but you'd need to know what length is required and a means to measure it without creating a spaghetti monster in the process.Is it easier to count turns or simply use up a measured length of wire? The end result will be the same.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rotor Winding Tooling

- Thread starter Jim

- Start date

How many Watts is that soldering iron? My old iron from 89 is only 15W and a bit limited for use on the bike harness, no good for those wires on the rotor, but great for PCB work. Combined with an air gun it is fab for desoldering ICs, just blasted the melted solder off but aim at the floor or out the door because the fine solder spray goes everywhere.

Recently I bought a new 80W iron with adjustable temperature. 7 Weeks ago I successfully used it to remove its first wart. Set it to 200 Celsius, gently tapped the wart until the nerves ceased to register pain, then held it on for 2x 4 seconds. It blistered and died. I had tried every medicated approach but none worked. Just have a slight red patch remaining now.

Recently I bought a new 80W iron with adjustable temperature. 7 Weeks ago I successfully used it to remove its first wart. Set it to 200 Celsius, gently tapped the wart until the nerves ceased to register pain, then held it on for 2x 4 seconds. It blistered and died. I had tried every medicated approach but none worked. Just have a slight red patch remaining now.

I successfully used it to remove its first wart.

Is that from the book of do-it-yourself surgery entitled Suture Self ?

Is that from the book of do-it-yourself surgery entitled Suture Self ?And, generally, for electronic work, a 30 - 40 watt iron is sufficient.

This may qualify as the greatest thread segue of all time!How many Watts is that soldering iron? My old iron from 89 is only 15W and a bit limited for use on the bike harness, no good for those wires on the rotor, but great for PCB work. Combined with an air gun it is fab for desoldering ICs, just blasted the melted solder off but aim at the floor or out the door because the fine solder spray goes everywhere.

Recently I bought a new 80W iron with adjustable temperature. 7 Weeks ago I successfully used it to remove its first wart. Set it to 200 Celsius, gently tapped the wart until the nerves ceased to register pain, then held it on for 2x 4 seconds. It blistered and died. I had tried every medicated approach but none worked. Just have a slight red patch remaining now.

59Tebo, the 80W is max output. If I set the controller to 300 Celsius then the element only fires up enough to maintain temperature. I checked the temperature control and it consistently gives the tip temp as within 10 - 15 Celsius.

Comes with a range of tips.

Comes with a range of tips.

It's an ancient dual heat Radio Shack. 20 or 40 watts. It's so old the wire are getting stiff. Do I replace the wires... or move into the 21st century? Hmmm....How many Watts is that soldering iron? My old iron from 89 is only 15W and a bit limited

Replace the wires, or don't, but it looks like a perfectly adequate tool to me. For the "heavy" stuff, I've got a Weller from the '70's, and it still works every time I pull the trigger. Even the "headlights" work! As long as I can get replacement tips, (I just put a new one on not that long ago, so it oughta last me for years), I'll keep it. It heats up fast, and it's great for auto/cycle/trailer wiring...

Last edited:

And regularly tighten the tip holding nuts.Replace the wires, or don't, but it looks like a perfectly adequate tool to me. For the "heavy" stuff, I've got a Weller from the '70's, and it still works every time I pull the trigger. Even the "headlights" work! As long as I can get replacement tips, (I just put a new one on not that long ago, so it oughta last me for years), I'll keep it. It heats up fast, and it's great for auto/cycle/trailer wiring...

Hondo57

XS650 Member

Reserved.....

Hondo57

XS650 Member

It's an ancient dual heat Radio Shack. 20 or 40 watts. It's so old the wire are getting stiff. Do I replace the wires... or move into the 21st century? Hmmm....

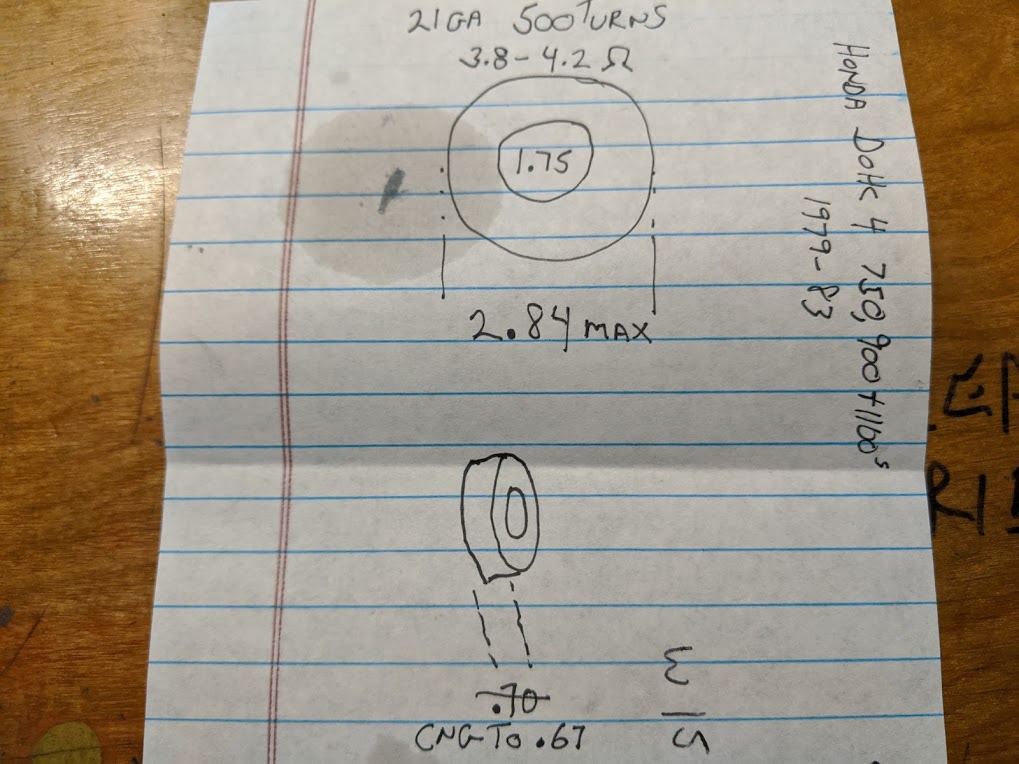

View attachment 158821

Hondo57

XS650 Member

Hi Jim, I have sent you a PM over on the 1100F forum about winding a rotor for me..Thanks

Thanks for letting me know Hondo. I'll pop on over there..

Hondo57

XS650 Member

It will be in your message box..not on the thread. Just need to send you the rotor and looking for an address..Thanks Jim.Thanks for letting me know Hondo. I'll pop on over there..

Hondo57

XS650 Member

Sorry you are having trouble with the log in. The code letters need to be capitalized when you enter them. Maybe that is the problem?Thanks for letting me know Hondo. I'll pop on over there..

I have read the terms and agree so I will mail it out tomorrow Jim. I left you another message on the other forum with my address and phone number.

The rotor is an Yamaha XJ 650. They mount right up on the CB900F engine and are lighter in weight. The details on the rotor are in my other message and I got them from the XJ forum. Thanks Jim..give a call or email with any questions.

Greg

Yeah, that's been the problem I guess. Not used to that stuff. Anyway, finally got logged in. I'll keep you updated one way or another.The code letters need to be capitalized when you enter them. Maybe that is the problem?

Just adding info here for a backup. Move along folks... nuttin' to see here....

Good Old Hogan's Heroes. I loved that Gonkulator Episode and how it fooled the Germans. I remember watching it mid to late 60s on a friends portable TV with a 6" screen. It was the thing to watch on Saturday night TV in NZ. I think it was replaced by Love American Style.

JAX71224

jax71224

Used machinisd friend for remove mass from ring on back of rodor on '83 cb750sc Nighdhawk and removed around a pound of spinning mass! Helped a bunch.. Rode once w/no rodor and WOW big acceleradion, quick revs........Burnoud for 80 feed!

Similar threads

- Replies

- 35

- Views

- 5K