Just look for the most toxic carcinogen on the market , with the biggest warning label , promising pain , death and testicular shrinkage. That’s the one you want, that’s the one that will work the best.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rotor Winding Tooling

- Thread starter Jim

- Start date

Will do. Gimme a few days. I have a weird work schedule.JRAY, find out what epoxy they're using...

OK, the last of the stuff I ordered finally showed up this afternoon. Nothin' else for it.... time to turn out a coil.....

402 turns of 22 ga. wire. Had to stay under 3.03" OD. Came out at 2.92". Yamaha calls for 5.25 ohms +/- 10%. So... 4.725 to 5.775 ohms. I hit exactly 4.8 ohms. I'll take it

I think on the next one I'll try to push 420-430 turns. Now I gotta let the red varnish cure for 12-16 hrs.

I'm gonna buy the wife a new toaster oven so's I can drag the old one out here in the garage..... Then I can cure it in 1 hr. at 185F

Then I can cure it in 1 hr. at 185F

402 turns of 22 ga. wire. Had to stay under 3.03" OD. Came out at 2.92". Yamaha calls for 5.25 ohms +/- 10%. So... 4.725 to 5.775 ohms. I hit exactly 4.8 ohms. I'll take it

I think on the next one I'll try to push 420-430 turns. Now I gotta let the red varnish cure for 12-16 hrs.

I'm gonna buy the wife a new toaster oven so's I can drag the old one out here in the garage.....

Well that’s really interesting. That’s really all there is inside a rotor? I always thought it was some crazy complex pattern, like an armature winding. That’s pretty cool!

Nope... just a plain wound, round coil. You could literally do a one off by hand.......I always thought it was some crazy complex pattern

One end of the coil, from the innermost winding, has to emerge from the inner, and is in contact with each layer. Given that many failed rotors show 0 ohms, I wonder if that's a risk zone, possible abrasion creating dead short. Would it be worth it to have a thin dielectric film, or spaghetti tube, to isolate/protect that emerging wire?

Putting it all together.

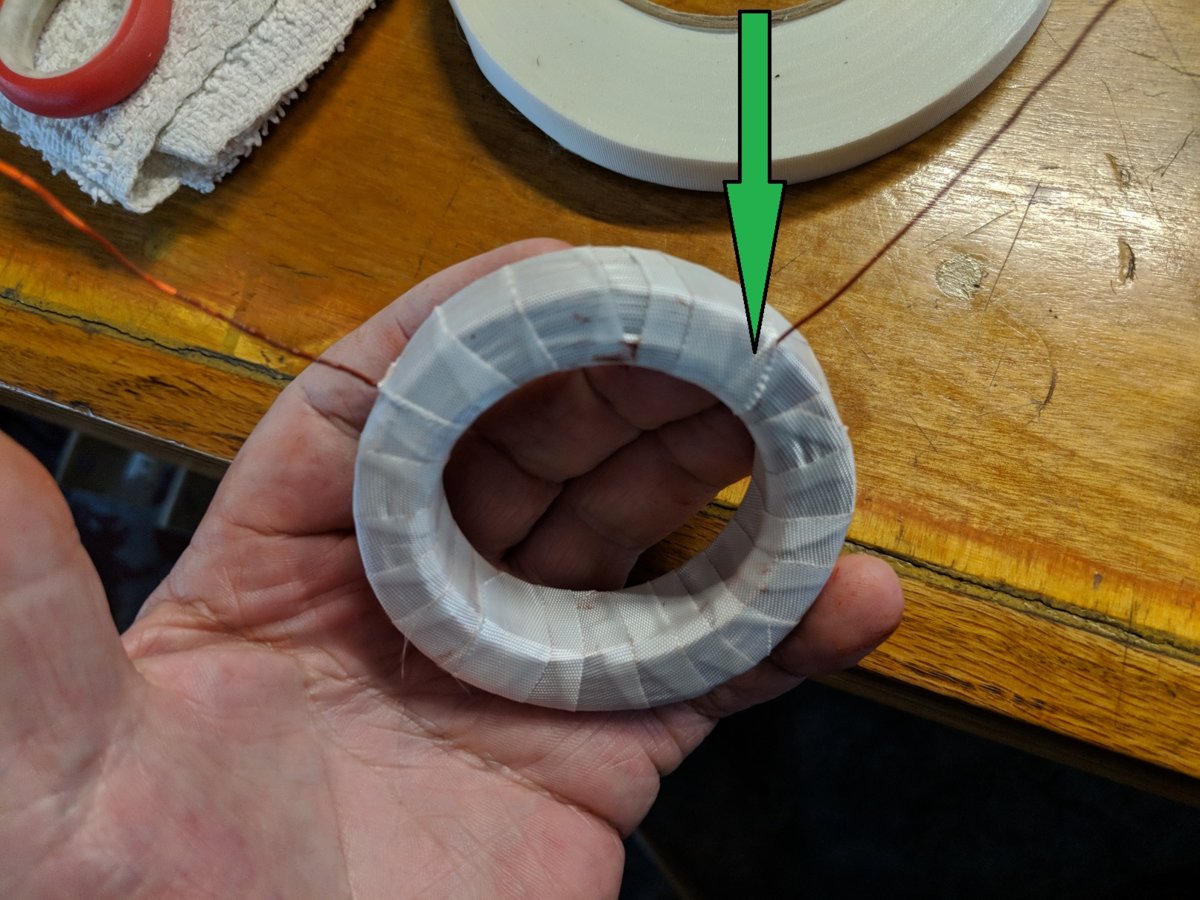

Removed the coil from it's winding form. The varnish was still a little tacky in places. Started wrapping with fiberglass tape....

That's been a concern to me also Steve. What I did was separate the wire and run a double wrap of tape around the coil, laid the wire radially across the coil and ran another double wrap around it. Should be well protected from abrasion...

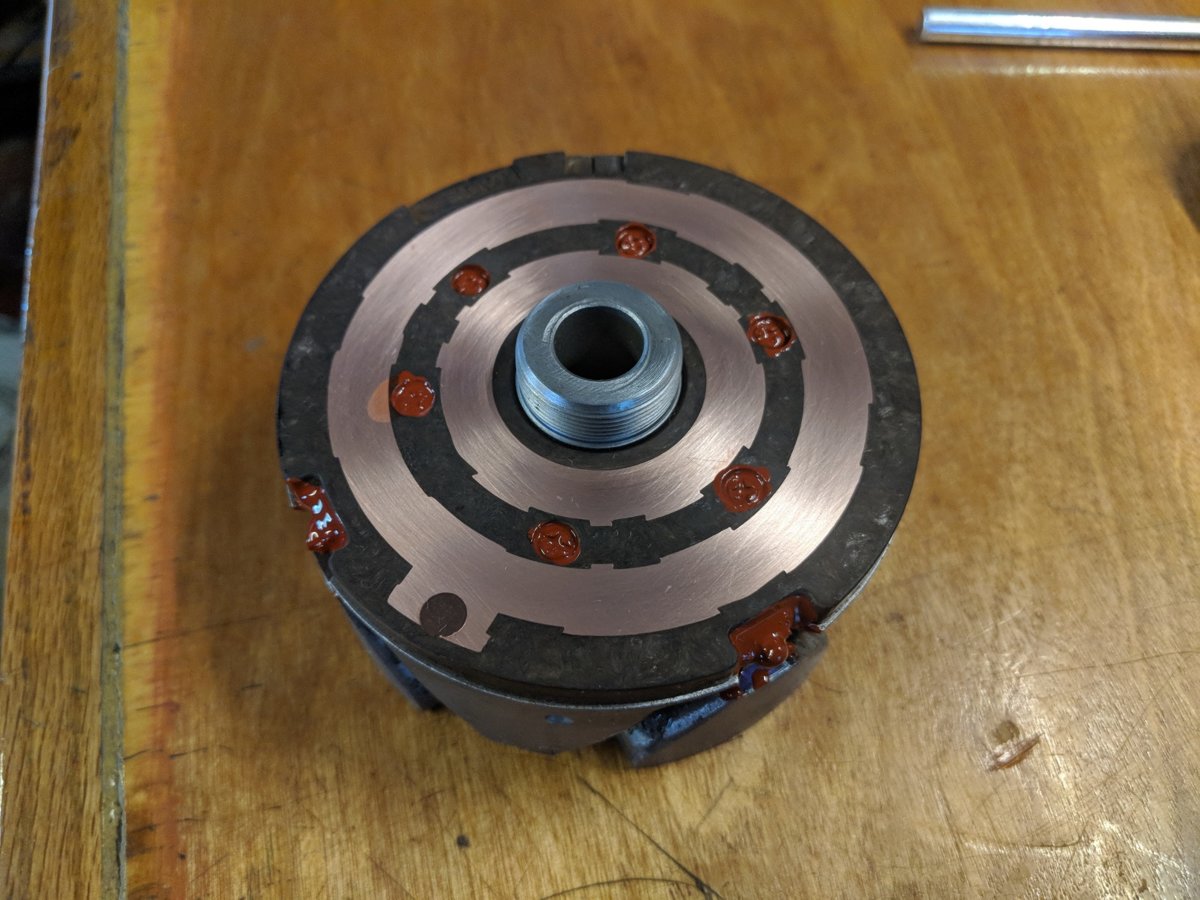

Here's a shot of the test fit........

Coated the coil in epoxy and pressed it all back together...

Reinstalled the slip ring and soldered the wires back on.....

.... and coated the solder and screws with the insulating varnish.

After it's all cured up, I can finally get the left side of my engine back together.

Removed the coil from it's winding form. The varnish was still a little tacky in places. Started wrapping with fiberglass tape....

One end of the coil, from the innermost winding, has to emerge from the inner, and is in contact with each layer. Given that many failed rotors show 0 ohms, I wonder if that's a risk zone, possible abrasion creating dead short. Would it be worth it to have a thin dielectric film, or spaghetti tube, to isolate/protect that emerging wire?

That's been a concern to me also Steve. What I did was separate the wire and run a double wrap of tape around the coil, laid the wire radially across the coil and ran another double wrap around it. Should be well protected from abrasion...

Here's a shot of the test fit........

Coated the coil in epoxy and pressed it all back together...

Reinstalled the slip ring and soldered the wires back on.....

.... and coated the solder and screws with the insulating varnish.

After it's all cured up, I can finally get the left side of my engine back together.

Last edited:

Awesome work Jim! Getting close......

Man that’s a slick bit of work! Very nice craftsmanship.

Too funny how simple it really is for something to cause headache for so many. You would think that the aftermarket would do a little more R&D to ensure the rotor would be at or over what stock is......wait a minute, that would be a stupid amount of money to do. Nevermind, lets see what the backyard guys can do first then copy and bring to market lol fingers crossed Jimd for your prototype to perform and last!!! Great details and write up!

Jim, how far is this going from here? You have some time and money into this. Do you have the time to take this further? Some "test beds" are needed now, some "test beds" that promise lots of mileage and proper installation.

Scott

Scott

Count me in!

Jim I would just like to say how much I enjoy these technical articles written by you and some of the other more knowledgeable members. I frankly never gave much thought to the construction and design of these components, but it has made me think and do some research to be able to better understand it. You also take excellent photos and write in a clear and concise manner. Good stuff!

Thanks Bob.

You're on the list Pete.

Scott, yeah.... I'm gonna move forward with this. Mine will be a test bed and there's an 80SG out in Az. that's gettin one for testing. I have 4 more "cores" I'll put out there for testing when I get 'em rewound. But right now, Fall is fast approaching and I want my resto on the road before the snow flies. So the next few weeks will be back on that.

You're on the list Pete.

Scott, yeah.... I'm gonna move forward with this. Mine will be a test bed and there's an 80SG out in Az. that's gettin one for testing. I have 4 more "cores" I'll put out there for testing when I get 'em rewound. But right now, Fall is fast approaching and I want my resto on the road before the snow flies. So the next few weeks will be back on that.

Thanks.......fingers crossed Jimd for your prototype to perform and last!!! Great details and write up!

If you were to let some of your epoxy fully cure, and then applied some more epoxy to the cured epoxy...…….would the uncured epoxy reactivate the cured epoxy? Would they separate at the glue line, or not?

Scott

Scott

Once an epoxy 'cooks off', it won't reactivate. It's a one time chemical reaction. The only way to bond fresh epoxy to 'cured' epoxy is to roughen the surface. That gets you to about 60-80% of original strength.

Glue line separation at the centrifugal forces we're talkin' is a distinct possibility.

Glue line separation at the centrifugal forces we're talkin' is a distinct possibility.

Good answer Jim. So, winding, potting and assembly, done without delays, could be an important factor.

Scott

Scott

Sorry Steve, forgot to respond to this...... I put punch marks on the three parts before I pressed it apart. A simple matter of lining up the dots.When these 3 are reassembled, is the alignment of the keyway with the timing mark assured, or do you have to keep your wits about you?

Similar threads

- Replies

- 35

- Views

- 5K