-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rust removal from inside gas tank

Beau

I like metal.

I have done a LOT of the electrode stuff, using stainless so it doesn't get as dirty. But it gives off Hydrogen, is nasty and kind of scares me.

Now I'm not sure what it will do to a super rusty tank, but it works! If you leave it to long it will eat the metal until it's gone.

Now I'm not sure what it will do to a super rusty tank, but it works! If you leave it to long it will eat the metal until it's gone.

MrBillohnooo

XS650 Addict

I saw a segment on Texas Country Reporter (a tv show) on a guy that restores license plates...that is what he uses to strip them. I tried it on some really rusty motor mounts and a few axle spacers. It does work, ya just gotta have a little patience. I was suprised that the vinegar actually ate under the paint, not the paint itself....pull out and rinse with water once a day, blow with air gun. Repeat daily till clean...parts did flash rust really quick even in the West Texas dry. But anyways, Yes! It works!

PetesPonies

XS650 Addict

Well vinegar will work, but its not as strong. Understand that even though phosphoric acid sounds dangerous . well its what is in colas that makes them work when removing rust. yes, you are drinking some phosphoric acid when you down that cola.

This site says coke is 55% phosphoric acid. I don't know how to interpret that but it probably doesn't mean it's harmless to mix the chemical grade stuff 50/50 with water and drink it.

http://keepwell.telenet.co.za/cola.htm

http://keepwell.telenet.co.za/cola.htm

lukach4

XS650 Addict

guess this thred proves that there's more than one way to skin a cat..... meow

da evil one

XS650 Addict

im polishing the crap outta a motor im building and im having a time getting between the fins. i should have it bead blasted i know but im too lazy and broke to go have it done. will vinigar clean it out in there?

pa23driver

XS650 Addict

vinegar... who would've thought. i tired the seafoam/gas mix with a bunch of nuts in the tank shaking it every so often which worked ok. i might have to give this vinegar thing a shot before spring

the-oz-slider

XS650 Addict

- Messages

- 170

- Reaction score

- 68

- Points

- 28

Go to your auto parts store and buy electical contact cleaner for your engine fin cleaning. It has some fancy chemicals in it that bring aluminum back to better than new and it wont hurt paint. I have been using it for carb cleaning and general engine cleanup and its absolutley brilliant. It also brings hub fins back to better than new. It will also put the sparkle back in old spokes. Works best on raw aluminum, not polished.

Best part is it doesnt hurt the paint. Its no good however on rust.

For my last tank job I did the electrolysis thing, and that removed about 80% of a 1" layer of rust from a 1969 R5 350 twin tank, then used vinegar over a period of about 3 months and it was just perfect.

Best part is it doesnt hurt the paint. Its no good however on rust.

For my last tank job I did the electrolysis thing, and that removed about 80% of a 1" layer of rust from a 1969 R5 350 twin tank, then used vinegar over a period of about 3 months and it was just perfect.

bluebikerblan

Geezer

What is milk stone remover and where do I buy it??

Thanks

t-o-s

Milk Stone Remover....MSR is a dilute solution of phosphoric acid commonly used to reduce "milkstone" in dairy service equipment....tanks, tubing, containers, equipment etc. It is commonly available at farm service dealers like "Tractor Supply" etc.

It's quite inexpensive, safe, easy to use, can be safely disposed of and does a super job

in reducing/removing iron oxide (rust). Some Home Depots will carry it but "Dairy Service Suppliers" are your best bet.

Here's a piece I put together sometime back on it's use..............

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Gas Tank Cleaning with Milk Stone Remover - MSR

Rust Removal with Phosphoric Acid based 'Milk Stone Remover'

This tip is from another forum.....I too had mixed results using electrolysis and Kreem and was better pleased with MSR (Milk Stone Remover) and a tank lining product called Red Kote which used to be red but now is blue in color. The tip is written by Bill Lane and posted on a CB 45O forum

"MSR is about 70% phosphoric acid, with an orange dye. Mix it 50% with water, fill the tank, come back later. It will save even the worse tanks. It's hell on rust, won't touch chrome. It will mess up paint if left long enough. Some tanks will get de-funkified in a few hours, some may take much longer - days or even a week or more, if they're really nasty. Those of you who have used Naval Jelly to remove rust are already familiar with how phosphoric acid removes (reduces)

rust by reducing red iron (ferric oxide) to loose black (ferrous) oxide and iron phosphate (also gray-black)

It (MSR) is also way less dangerous than muriatic (hydrochloric) or sulfuric acid to work with. If you get some on you, at least you have a chance to make it inside and rinse it off before it burns the livin' snot out of you. No noxious fumes either. I'm a degreed chemist, I've seen what acids can do, so I stay with MSR, it's much safer to work with.

I've also had unsatisfactory results with electrolysis. It works "line of sight", meaning that if the sacrificial electrode can't "see" the area nothing will happen . That means that convoluted volumes or parts (like tanks) will yield indifferent results. MSR also works better on flat pieces. I keep a big 60-quart cooler full of MSR solution which I process nearly everything with it. Some people claim it leaves some sort of protective coating that prevents further rust. I have not found that to be the case at all. In my experience, you can see the rust re-forming before your very eyes. So, you need to quickly either paint the piece, spray with WD 40 or light oil. For a tank case, fill quickly (or swish around) some heavy 2-stroke gas/oil mixture to coat it while you prepare to do something else with it.

Everyone has a favorite tank "sealer" - I prefer Red-Kote myself, use what you prefer. Although Red-Kote has changed recently, it's now blue, but the same stuff. If you go with Red-Kote, mix it down a bit with acetone to make it easier to use. The stuff is really viscous out of the can." -endquote-

Other tank lining products are POR 15 , which a lot of people like as well. And Kreem, both are products I have used with difficulty and mixed results.

Milk Stone Remover, MSR, is available from a variety of Dairy Service products suppliers. I found and purchased MSR from a localTractor Supply store.

Hope this helps with a rather messy and onerous task at best, It did for me and was clearly the best to use of the bunch for me.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Only thing I would add today is to consider KBS Coatings supplied products as well their "Gold Standard" tank liner is also excellent and perhaps even more resistant to ethanol containg gas mixtures even E-85 I am not a fan of "Kreem" either to apply or in service. I prefer Red-Kote (even though now Blue in color) and Gold Standard (newer to me)

Plan to do more tanks soon (when it warms up a bit) and get more experience with both

Evaporust and Gold Standard. Evaporust is a new easy to use de-ruster I picked up at Harbor Freight which worked well in my first recent experience. MSR to de-rust and Red-Kote are still the frame of reference and standbys. Blue

Last edited:

bluebikerblan

Geezer

The working element of Vinegars is acetic acid really effective in removing lime scales etc. in your bathroom, coffee pots, etc.

Phosphoric acid.... also a milder acid when diluted is comparatively safe to use and is particularly effective in reducing red iron oxide (ferric oxide to ferrous oxide) and iron phosphate. It's also the active ingredient in Naval Jelly (rust remover) is btw. Yes, it is an ingredient in coke and many other products and widely used in a variety of food products at low percentages for a variety of reasons.

Apologies.....the previous post is a repeat of a previous repost ....MSR guys...cheap, easy, safe

de-ruster

Phosphoric acid.... also a milder acid when diluted is comparatively safe to use and is particularly effective in reducing red iron oxide (ferric oxide to ferrous oxide) and iron phosphate. It's also the active ingredient in Naval Jelly (rust remover) is btw. Yes, it is an ingredient in coke and many other products and widely used in a variety of food products at low percentages for a variety of reasons.

Apologies.....the previous post is a repeat of a previous repost ....MSR guys...cheap, easy, safe

de-ruster

Last edited:

gentlemanjim

More Wrenchin than Ridin

Once de-rusted with electrolsis are you saying use MSR or Evaporust? You mention both or jsut phosforic acid??

bluebikerblan

Geezer

No Jim.....Using MSR or Evaporust are just chemical derusters an either/or versus electrolysis. All are really just alternative ways of reducing the iron oxide to a non bonded ferrous electrolytic form which can then be cleaned out and removed. 2 chemical methods versus one electro-mechanical.

Many primers (which can also be used to enhance adhesion of the subsequent lining material metal) are also phosphates, usually zinc phosphates not to confuse the matter.

Once de-rusted, cleansed, rinsed... dry the interior tank sufaces well, very well. I use hot air hair dryer blowers and then proceed with whichever lining system you choose, including a priimer if yours calls for one. These surfaces are now very prone to re-oxidize (rust) after derusting...

so proceed as quickly as practical to coat and protect as you choose. All these methods work best, it seems when things are reasonably warm, 70 plus if possible, much like painting.

MSR (dilute phosphoric acid) or Evaporust are just derusting (reducing) agents. I do not have the specific chemistry, at this point into the chemistry of "Evaporust"....will advise if/when known. Update....1/11/11 Evaporust reduces the rust (ferric oxide) by some chelating agent

(not phosphoric acid) to a chelated form of ferrous sulfate (which is also black in color btw).

The reduced (derusted product) result when MSR (dilute phosphoric acid) is used is principally ferrous phosphate also dark grey/black. The two products are hard to distinquish between on a cursory basis without a lab. Blue

Many primers (which can also be used to enhance adhesion of the subsequent lining material metal) are also phosphates, usually zinc phosphates not to confuse the matter.

Once de-rusted, cleansed, rinsed... dry the interior tank sufaces well, very well. I use hot air hair dryer blowers and then proceed with whichever lining system you choose, including a priimer if yours calls for one. These surfaces are now very prone to re-oxidize (rust) after derusting...

so proceed as quickly as practical to coat and protect as you choose. All these methods work best, it seems when things are reasonably warm, 70 plus if possible, much like painting.

MSR (dilute phosphoric acid) or Evaporust are just derusting (reducing) agents. I do not have the specific chemistry, at this point into the chemistry of "Evaporust"....will advise if/when known. Update....1/11/11 Evaporust reduces the rust (ferric oxide) by some chelating agent

(not phosphoric acid) to a chelated form of ferrous sulfate (which is also black in color btw).

The reduced (derusted product) result when MSR (dilute phosphoric acid) is used is principally ferrous phosphate also dark grey/black. The two products are hard to distinquish between on a cursory basis without a lab. Blue

Last edited:

bluebikerblan

Geezer

It seems likely that more and more of us are going to come across and be using Evaporust as a safe, easy and effective derusting agent. Since I had done some work with Milk Stone Remover- MSR diluted phosphoric acid to remove rust from motorcycle fuel tanks, I've been begun some comparative evaluations.

Evaporust is now broadly available http://evaporust.com/evaporust.html

I found it nearby at a Harbor Freight outlet and I've noticed it being carried in their catalog as well.

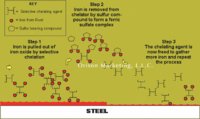

While phosphoric acid reduces rust,(red iron oxide ie ferric oxide bonded to the metal surface of the tank) to loose forms ferrous oxide (black/gray) and ferrous phosphate (black/gray). Evaporust appears to work via a chelating agent which selectively reduces the red iron oxide, (ferric oxide) to a chelated complex of black iron sulfate (ferric sulfate), as illustrated below.

Evaporust appears to be a very interesting and different chemistry to removers employing phosphoric acid. Once I can get my garage-shop above 70 degrees, I'll be doing more extensive comparisons to my longtime favorite MSR. Either method needs some warmth to work quickly and well. Even more safety and green disposability are attractive features. Blue

Evaporust is now broadly available http://evaporust.com/evaporust.html

I found it nearby at a Harbor Freight outlet and I've noticed it being carried in their catalog as well.

While phosphoric acid reduces rust,(red iron oxide ie ferric oxide bonded to the metal surface of the tank) to loose forms ferrous oxide (black/gray) and ferrous phosphate (black/gray). Evaporust appears to work via a chelating agent which selectively reduces the red iron oxide, (ferric oxide) to a chelated complex of black iron sulfate (ferric sulfate), as illustrated below.

Evaporust appears to be a very interesting and different chemistry to removers employing phosphoric acid. Once I can get my garage-shop above 70 degrees, I'll be doing more extensive comparisons to my longtime favorite MSR. Either method needs some warmth to work quickly and well. Even more safety and green disposability are attractive features. Blue

Attachments

Last edited:

gentlemanjim

More Wrenchin than Ridin

I ran the electrolosys for a couple days got a lot of rusty crud out and then it started eating the sacrafical anode. So I shut it down.

I wonder why that took place???

Next I want to flush with evaporust before sealing with Red-Kote, I used it in the past and it did a good job on imersed parts.

How to maximize 1 gallon of evaporust in a 4 gallon tank??

1. Let it soak on the bottom overnight?

2. Rotate it on each side and them upside down for a day each?

3. Dilute it with water?

4. Buy more than one gallon? its not cheap.

I wonder why that took place???

Next I want to flush with evaporust before sealing with Red-Kote, I used it in the past and it did a good job on imersed parts.

How to maximize 1 gallon of evaporust in a 4 gallon tank??

1. Let it soak on the bottom overnight?

2. Rotate it on each side and them upside down for a day each?

3. Dilute it with water?

4. Buy more than one gallon? its not cheap.

I'd pass on the evaporust if I was using Red-Kote. Red-Kote doesn't require a bare metal start.

gentlemanjim

More Wrenchin than Ridin

I just want to get it as clean as possible. This tank was a diaster rusted right through in places. I had to braze weld metal patches and then sealed the outside with expoxy just incse there were smal breaches in my welding. Its been a long process adn I want o be sure its done right. The tank is an unobtainium item only found one used in the UK. NOS is around $500.00

Check it out

Check it out

bluebikerblan

Geezer

Next I want to flush with evaporust before sealing with Red-Kote, I used it in the past and it did a good job on imersed parts.

How to maximize 1 gallon of evaporust in a 4 gallon tank??

1. Let it soak on the bottom overnight?

2. Rotate it on each side and them upside down for a day each?

3. Dilute it with water?

4. Buy more than one gallon? its not cheap.

GMJ....Some combinations of 1, 2, 4 may be good ideas......skip #3. Remember to save your solution, it can be used several times, don't let the black color fool you. Make sure things are warm ....tank, solutions, ambient air. 70 degrees +++

What you want is wet interior surface area contact. I have used things like #5. partially inflated kitchen garbage bags acting as bladders to displace fluid tp wet more surface area. then move things about now and then.....makes less go further and do more.

However.....I bought 4 gallons, have put it in a 5 gallon heavy duty jug with a tap/spigot and will re-use and re-use. Doing the tank in some sort of catch-tub..kiddy swimming pool? is a good idea too. accidents do happen. Reasons why I like both MSR & Evaporust (hopefully) they are both quite safe to use/spill.

(I've not done a tank with Evaporust yet, just pieces Pls. advise your results) Blue

I'm not an Electrolysis guru (in fact I had a couple of disasters) Perhaps we can get TRG (The Retired Gentleman) or others to chime in on that one. Blue

PS....One good reason to use Evaporust or MSR even though the liner material (Red-Kote or POR-15 will encapsulate it obviating the need to remove it) is. It kills the oxidation process and environment at the metal/metal-oxide interface. The liner then protects clean metal surfaces rather than encapsulating a lot of reduced rust crud which usually plugs you tap spouts too btw.

Pipe cleaners to clear the spouts near the end.

Last edited:

gentlemanjim

More Wrenchin than Ridin

Thanks BlueBB - that's my plan to use Evaposrust worked good on parts. I'm gonna try some inflated zip looks to displace the solution to cover more of the inner surface. After a few days I'll drain, filter the evaporust and re-apply if necessary. Its warm down here in S. FL. so temps will be ok. I'm not in a rush just want to do the best prep and seal job possible.

zeroxs650

XS650 Addict

I used CLR in my Yamaha tank and left it in for a week. I would turn the tank over and over and after a week, drain and flushed and it was clean. Cheapest mod I did...

Similar threads

- Replies

- 16

- Views

- 237